Composite admixture for cement or high-performance concrete and preparation method thereof

A technology of high-performance concrete and composite admixtures, applied in the direction of climate sustainability, sustainable waste treatment, solid waste management, etc., to achieve the effects of optimized performance, optimized particle gradation, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The present invention will be further described below by way of examples.

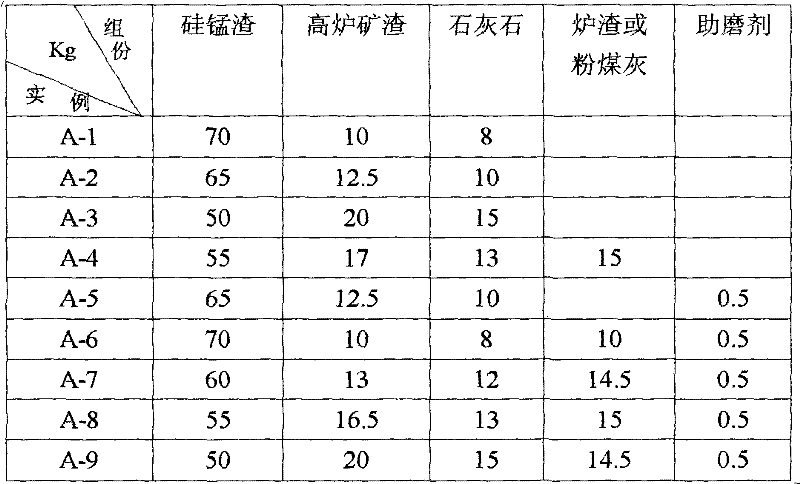

[0047] Table 1 Admixture ingredients for cement (A)

[0048]

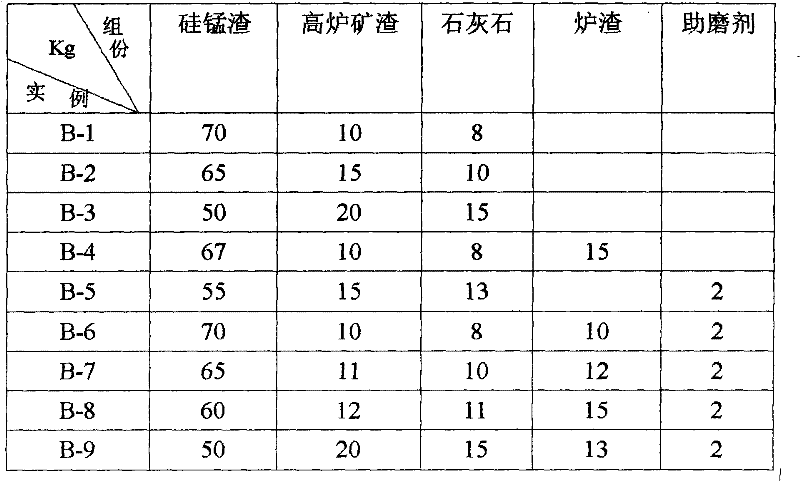

[0049] Table 2 Ingredients of admixtures used in high performance concrete (B)

[0050]

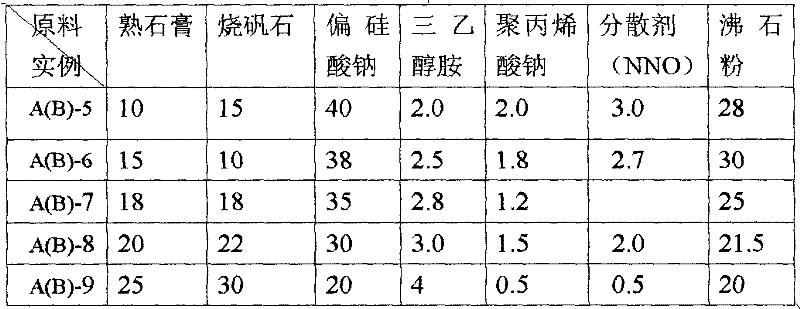

[0051] The composition of the grinding aids in Table 1 and Table 2 is shown in Attached Table 1.

[0052] Attached Table 1 Ingredients of Grinding Aids (Mass Percent%)

[0053]

[0054] The samples in Table 1 and Table 2 were tested with reference to the S95 grade slag powder in GB / T 18046-2008 Granulated Blast Furnace Slag Powder Used in Cement and Concrete, and the results are shown in Table 3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com