Process for removing nitrogen and phosphor using traditional waste water treatment process

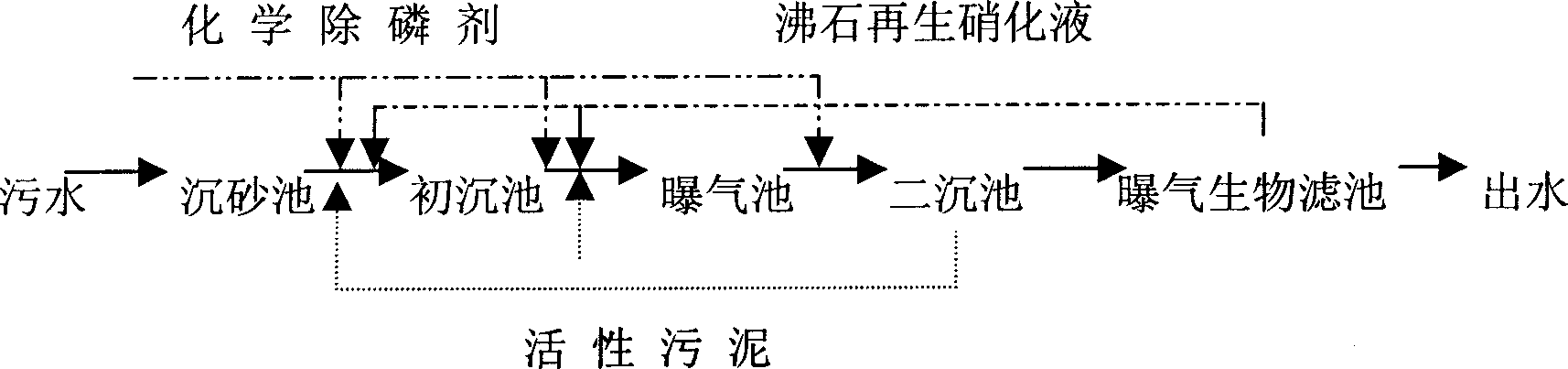

A technology for nitrogen and phosphorus removal and sewage treatment, applied in water/sewage multi-stage treatment, biological water/sewage treatment, water/sludge/sewage treatment, etc., can solve the problems of low removal rate of nitrogen and phosphorus, and maintain Processing capacity, convenient transformation, good technical and economical effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0014] An urban sewage treatment plant adopts the adsorption regeneration process. The removal rate of ammonia nitrogen is 10% to 30%, and the removal rate of TP is less than 20%.

[0015] The technical transformation of the sewage treatment plant adopts this nitrogen and phosphorus removal process, that is, the sewage enters the aeration tank and the secondary sedimentation tank after passing through the grit chamber (the original process technical parameters are still used for the grit chamber, aeration tank and secondary sedimentation tank), and the muddy water After separation, the sewage enters the biological aerated filter, and is discharged after being adsorbed for 45 minutes. 60% of the activated sludge is returned to the aeration tank, and the remaining part of the activated sludge and the remaining sludge are returned to the primary sedimentation tank. Add the mixed salt of aluminum sulfate and ferrous sulfate to the end of the grit chamber, the end of the primary se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com