Process and system of recycling magnesium sulfate and ammonium sulfate mixed wastewater

A technology of mixed wastewater and treatment process, which is applied in multi-stage water treatment, water/sewage treatment, water/sludge/sewage treatment, etc., which can solve the problems of difficult and low-cost effective separation, lack of market demand for mixtures, and secondary pollution of the environment and other issues, to achieve significant technical and economic effects, easy industrial implementation, and reduce the cost of waste liquid treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

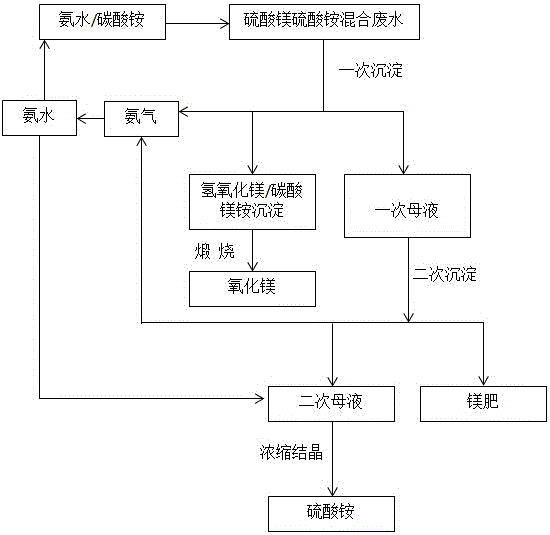

[0020] A magnesium sulfate ammonium sulfate mixed wastewater resource treatment process, the steps are as follows:

[0021] 1. One-time sedimentation and separation of magnesium ions in mixed wastewater

[0022] In the first-time circulation reactor, start stirring, add 2% magnesium-containing ammonium sulfate-magnesium sulfate mixed wastewater and ammonium carbonate solution in sequence, keep the pH value of the reaction system at 9.5, control the temperature at 65°C during the reaction process, mix and stir for 40 minutes, and once Precipitation reaction; after the reaction, the material enters the primary filter press to obtain a magnesium carbonate filter cake, and the filter cake goes to step 3. The mother liquor contains ammonium sulfate and 0.1%-0.5% magnesium ions, and is transported to the secondary precipitation tank, and the tail gas enters the absorption tower Ammonia water is produced, and the produced ammonia water is added to the ammonium carbonate solution and ...

Embodiment 2

[0030] A magnesium sulfate ammonium sulfate mixed wastewater resource treatment process, the steps are as follows:

[0031] 1. One-time sedimentation and separation of magnesium ions in mixed wastewater

[0032] In the primary circulation reactor, start the stirring, add 4% magnesium-containing ammonium sulfate magnesium sulfate mixed wastewater and ammonia solution in sequence, keep the pH value of the reaction system at 10.5, control the temperature at 55°C during the reaction process, and mix and stir for 45 minutes. Precipitation reaction; after the reaction, the material enters the primary filter press for pressure filtration, and the filter cake goes to step 3. The mother liquor contains ammonium sulfate and 0.1%-0.5% magnesium ions, and is transported to the secondary precipitation tank, and the tail gas enters the absorption tower to produce ammonia water. The ammonia water taken is added to the ammonium carbonate solution and the ammonium sulfate recovery system to pa...

Embodiment 3

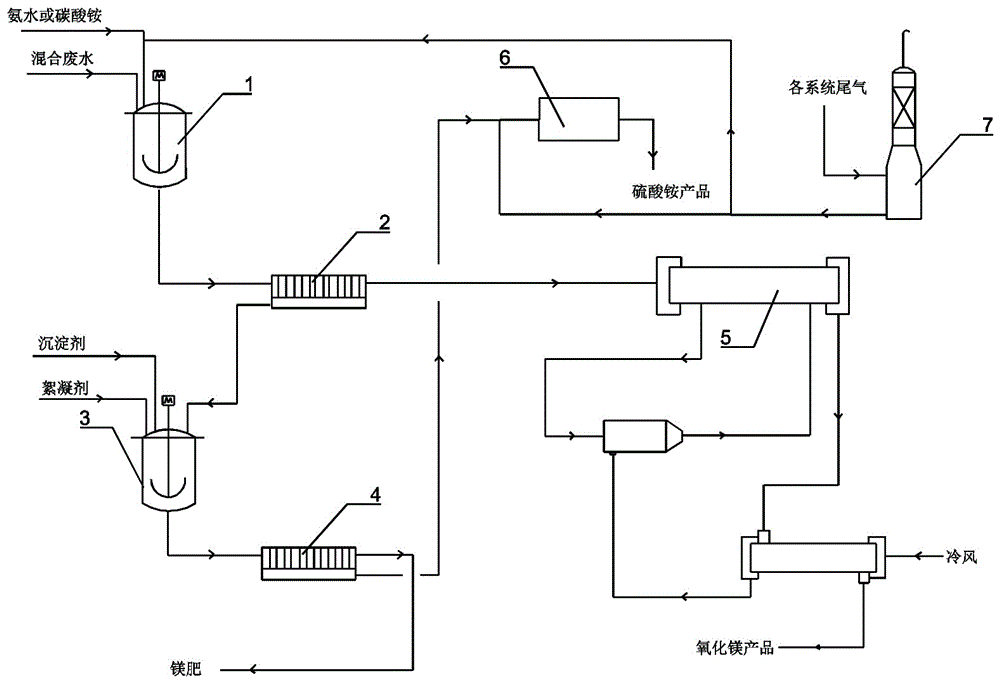

[0040] Such as figure 2 As shown, a magnesium sulfate ammonium sulfate mixed wastewater resource treatment system described in this embodiment includes a primary circulation reactor 1, a primary filter press 2, a secondary precipitation kettle 3, a secondary filter press 4, and a calcination system 5 , ammonium sulfate recovery system 6 and tail gas absorption system 7; the outlet of primary circulation reactor 1 is connected with the inlet of primary filter press 2, the solid outlet of primary filter press 2 is connected with the inlet of calcining system 5, and the outlet of primary filter press 2 The liquid outlet is connected to the inlet of the secondary sedimentation kettle 3, the outlet of the secondary sedimentation kettle 3 is connected to the inlet of the secondary filter press 4, the solid outlet of the secondary filter press 4 is discharged, and the liquid outlet of the secondary filter press 4 is connected to The inlet of the ammonium sulfate recovery system 6, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com