Process and system for recycling high-chloride high-concentration non-degradable organic wastewater

A high-chloride, organic wastewater technology, applied in the field of resources and environment, can solve the problems of difficult investment and operating costs, narrow process application range, complex process, etc., and achieve the effects of easy industrial implementation, significant technical and economic effects, and low operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

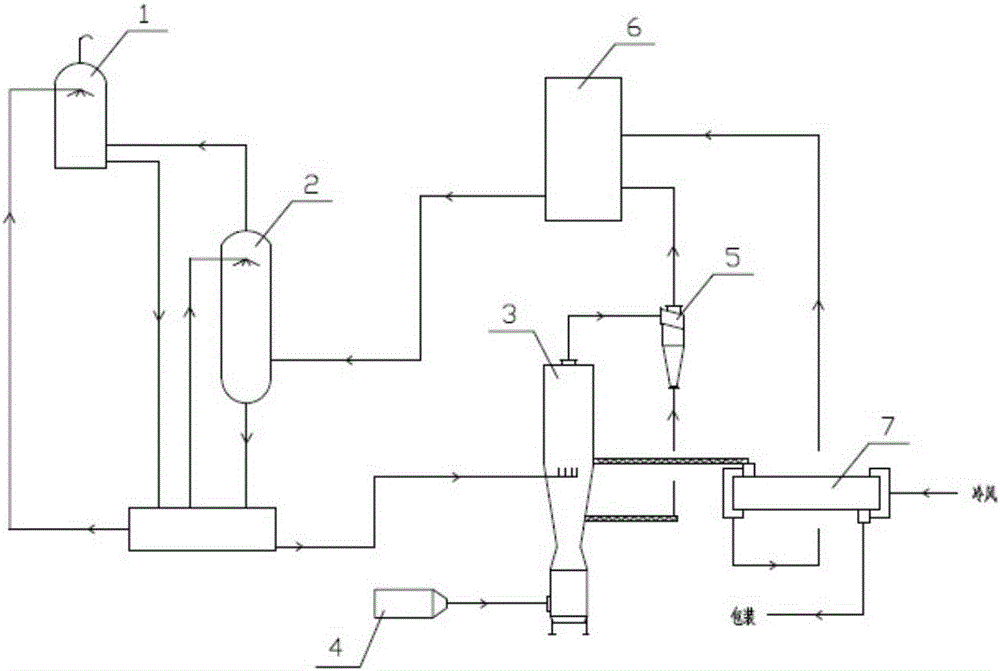

[0027] A high-chloride, high-concentration refractory organic waste water recycling system, the steps are as follows:

[0028] 1) Wastewater spray quenching and concentration process

[0029] Step 2) The high-temperature flue gas at 1100°C from the secondary combustion chamber enters the spray quenching tower from the bottom, and the high-salt and high-organic waste water is sprayed on the upper part of the tower, and the flue gas is cooled to 180°C in an instant, eliminating the conditions for dioxin generation; at the same time, the waste water The water in the water is evaporated rapidly, and the concentration is rapidly increased; the tail gas of the spray quenching concentration tower is treated at 90°C and discharged at 90°C; the tail gas absorption liquid enters step 1) waste water storage tank; the concentrated crystals are transported to step 2) high temperature boiling oxidation process.

[0030] 2) High temperature boiling circulation oxidation system

[0031] From...

Embodiment 2

[0034] A high-chloride, high-concentration refractory organic waste water recycling system, the steps are as follows:

[0035] 1) Wastewater spray quenching and concentration process

[0036] Step 2) The 1200°C high-temperature flue gas from the secondary combustion chamber is sprayed from the bottom of the quenching tower, and the upper part of the quenching tower is sprayed with high-salt and high-organic waste water, and the flue gas is instantly cooled to 180°C, eliminating the conditions for dioxin generation; The water in the water is evaporated rapidly, and the concentration is rapidly increased; the tail gas of the spray quenching tower is discharged at 80°C after passing through the tail gas treatment tower; the tail gas absorption liquid enters step 1); the concentrated crystals are transported to step 2) high-temperature boiling oxidation furnace system to decompose organic matter ,.

[0037] 2) High temperature boiling cycle oxidation process

[0038] From step 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com