Annular bearing forging triple-package forging technology

A ring bearing and forging technology, applied in the field of bearing forging, can solve the problems of low material utilization and heavy weight

Inactive Publication Date: 2010-08-25

李金国 +1

View PDF5 Cites 22 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

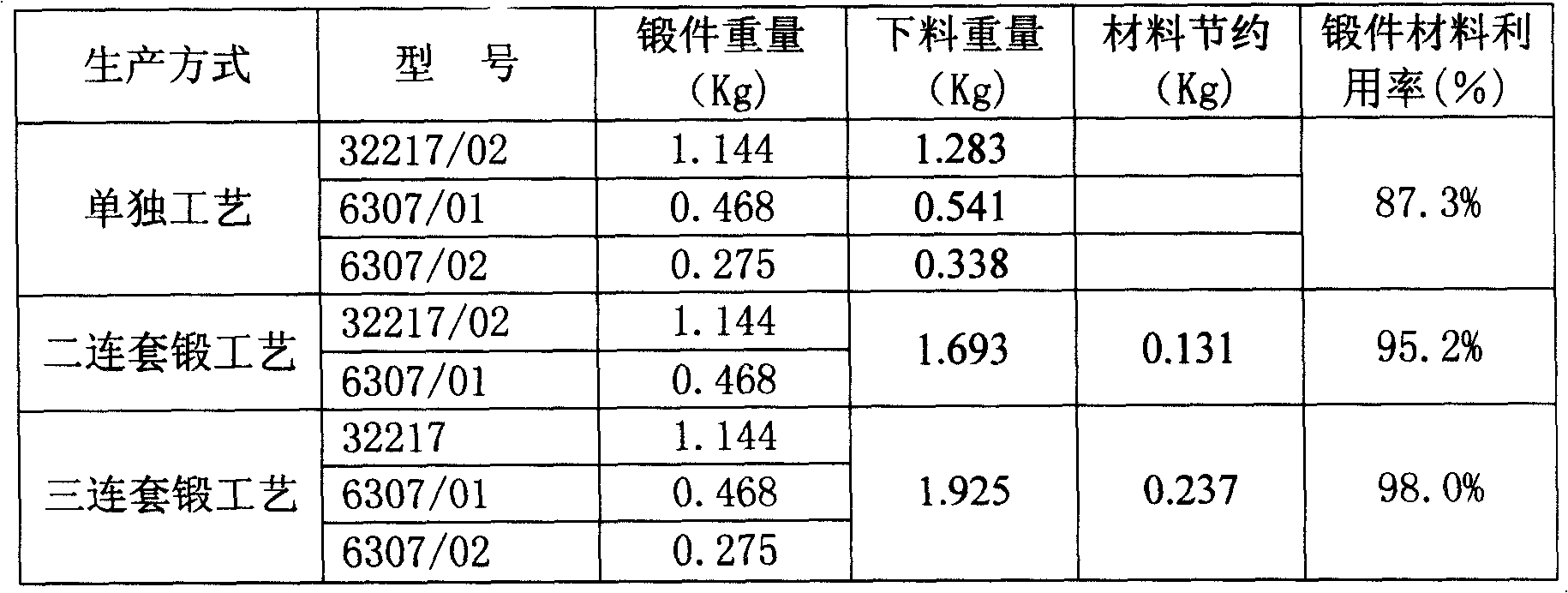

At present, most of the ring bearing forgings in automobiles, motorcycles and machinery are produced in a single piece on pressure equipment such as crank presses and hole reaming machines. , heavier weight, lower material utilization

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

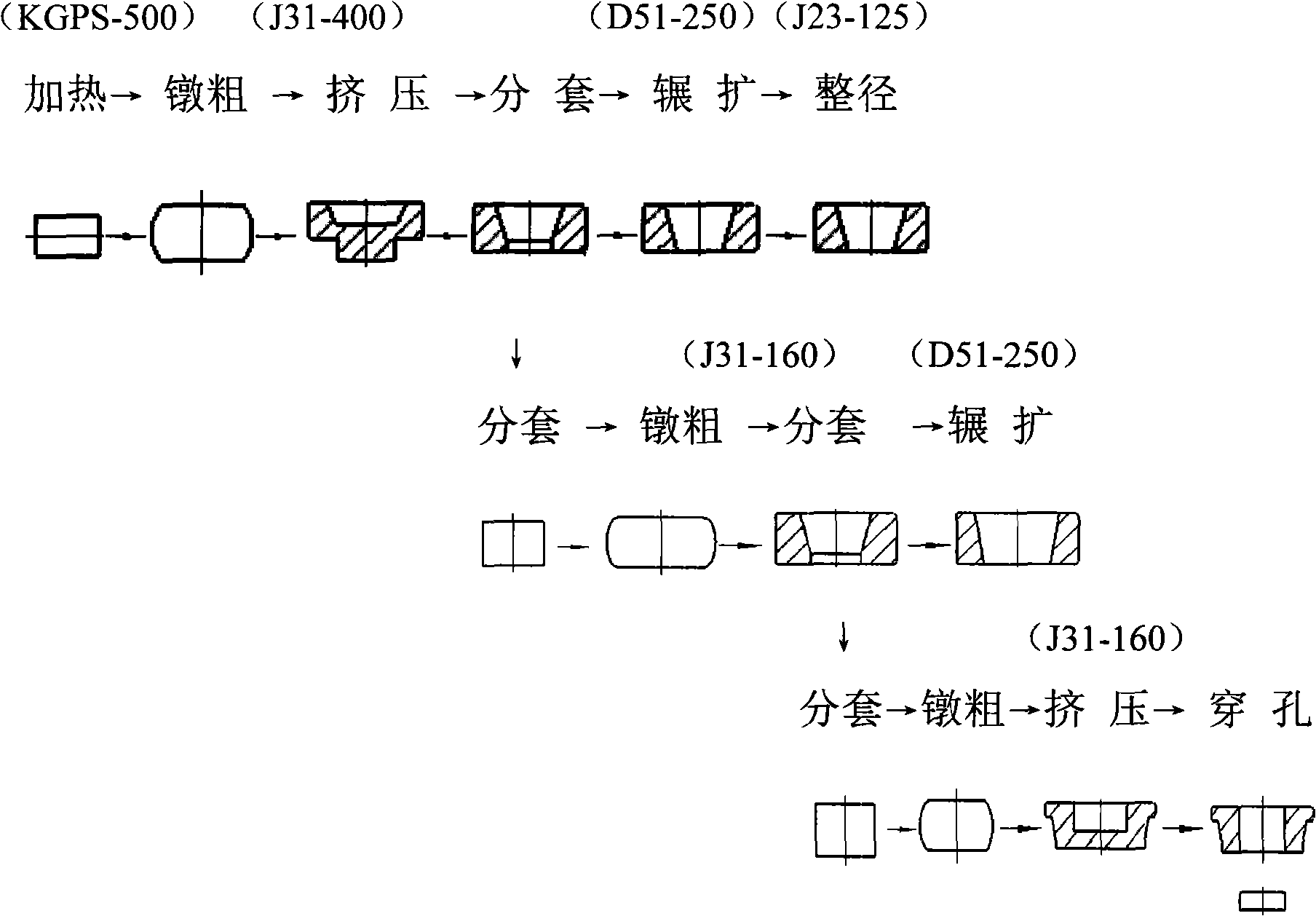

The invention relates to an annular bearing forging triple-package forging technology belonging to the technical field of bearing forging and mainly solving the problem of lower stock utilization in the traditional annular bearing single and double-package forging technology. The technology is mainly characterized in that: (1) a steel section with the weight of 1.500-2.700kg and the diameter of 55-70 is heated to forging temperature, divided into two parts, i.e., an annular big bloom and an annular medium-small bloom, after the processes of upsetting and package separation; (2) the annular big bloom is made into a big annular bearing forge by the processes of ring rolling, restricking and cooling; (3) the annular medium-small bloom is separated into two parts, i.e., an annular medium bloom and an annular small bloom, after the processes of upsetting and package separation; (4) the annular medium bloom is made into a medium annular bearing forge by to the processes of ring rolling and cooling; and (5) the annular small bloom is made into a small annular bearing forge by the processes of ring rooling, extrusion, punching and cooling. The invention mainly adopts a novel technology of punching-expanding horizontal package separation and the annular bearing forging triple-package forging technology, thereby realizing the simultaneous production of annular bearing forgings in big, medium and small sizes.

Description

technical field The invention belongs to the technical field of bearing forging. In particular, it relates to a three-set forging process for ring bearing forgings. Background technique At present, most of the ring bearing forgings in automobiles, motorcycles and machinery are produced in a single piece on pressure equipment such as crank presses and hole reaming machines. , heavier weight, lower material utilization. How to further reduce core weight and improve material utilization. Finding a new forging process method is of great significance for reducing production costs. Contents of the invention The object of the present invention is to provide a triple-set forging process with high material utilization rate and low production cost, which is suitable for the production of ring bearing forgings in small batches or large batches. The technical solution of the present invention is: a three-set forging process for ring bearing forgings, which is characterized in th...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): B23P15/00B21J1/06B21J5/06B21H1/06

Inventor 李金国程学正

Owner 李金国

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com