High pier continuous beam side span cast-in-place section and closed section integrated construction system and construction method

A technology of closing long sections and side spans, which is applied in the direction of bridges, bridge construction, erection/assembly of bridges, etc., can solve the problems of difficult foundation treatment for support erection, poor stability of support slenderness, and difficulty in erecting support, etc., to achieve high resolution The problem of erecting pier brackets, convenient construction, and the effect of avoiding construction of a large number of brackets

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to enable those skilled in the art to better understand, the technical solution of the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

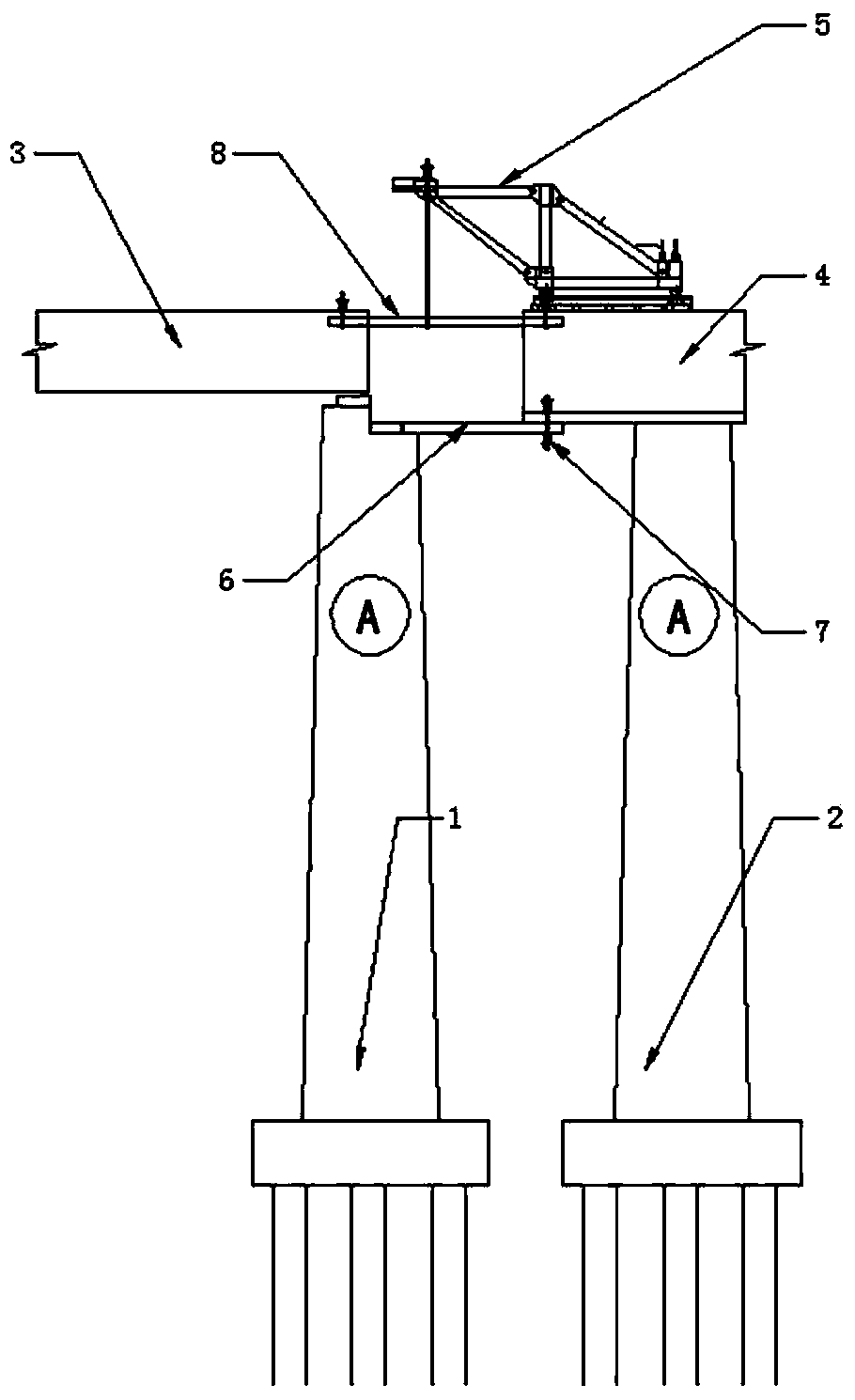

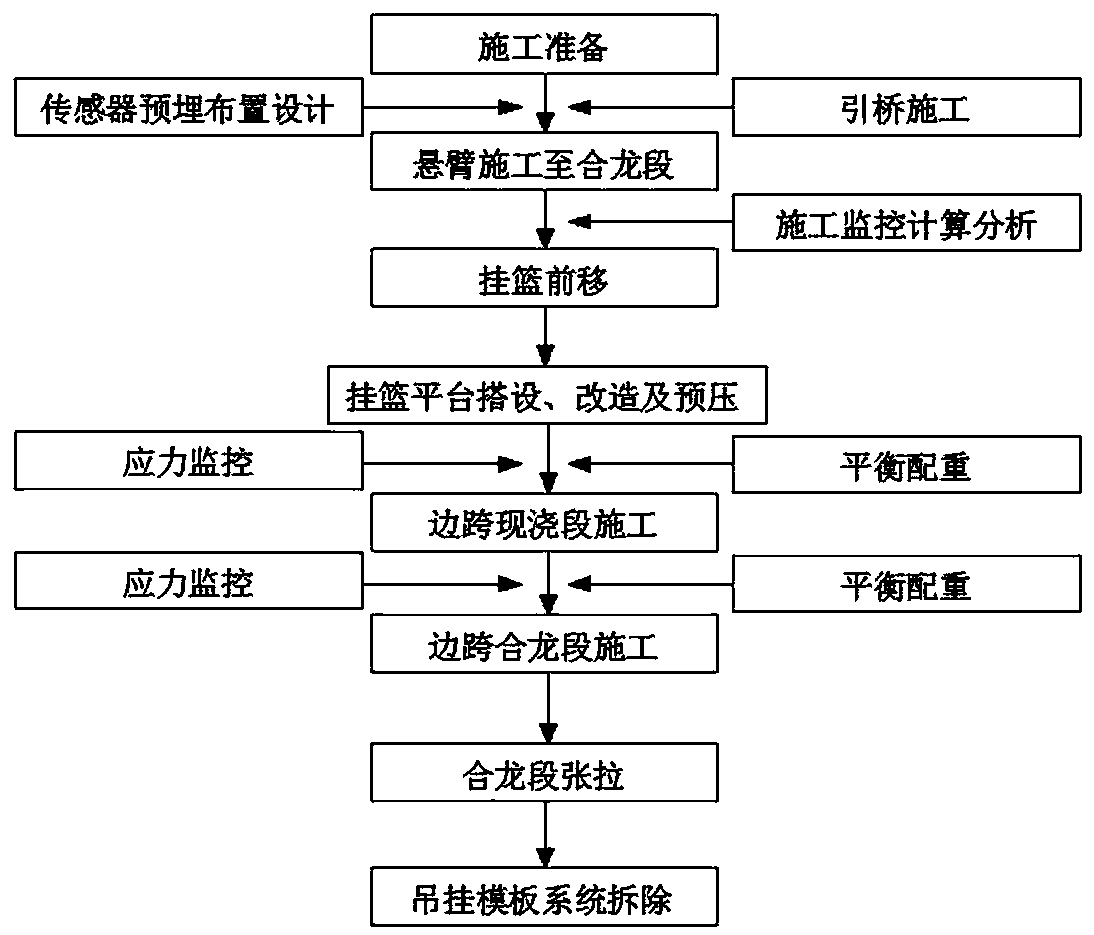

[0028] like figure 1 The integrated construction system of the side-span cast-in-situ section and closing section of the continuous beam of the high pier shown includes the side-span pier body 1, the mid-span pier body 2 closest to the side-span pier body 1, the side-span pier body 1 erected on the side-span pier body 1 The constructed beam 3 and the continuous beam 4 erected on the mid-span pier body 2 and close to the side of the constructed beam 3 are characterized in that it also includes a hanging basket 5, a bottom plate longitudinal beam 6 and a bottom plate crossbeam 7, and the hanging basket 5 The function is installed on the continuous beam 4, one end of the floor longitudinal beam 6 is erected on the side span pier body 2, and the other end is erected ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com