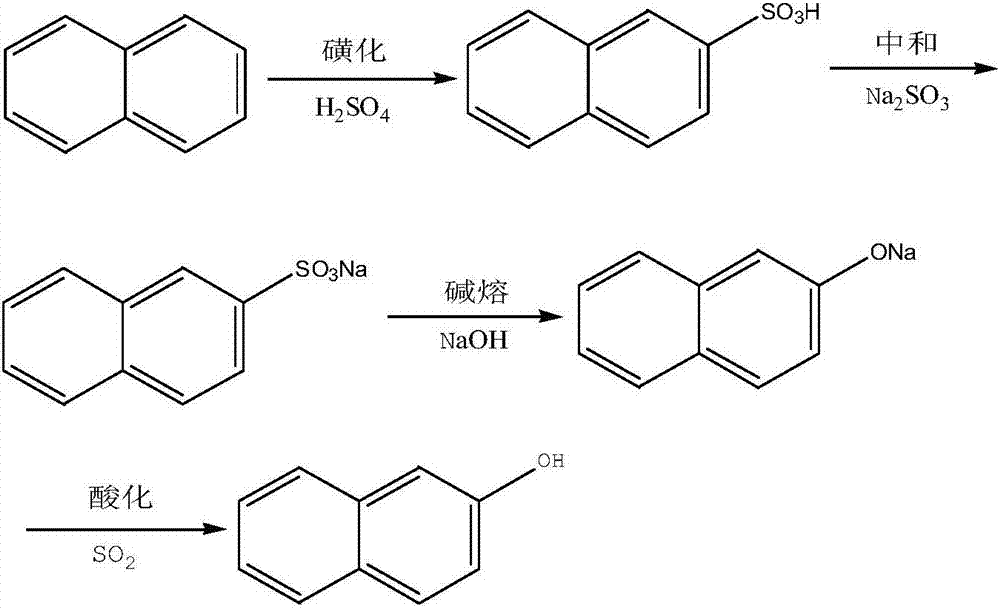

Method for treating and resourcefully utilizing dye intermediate such as 2-naphthol production wastewater

A technology for dye intermediates and wastewater production, which is used in neutralizing water/sewage treatment, water/sewage treatment, chemical instruments and methods, etc. The problem is solved, the treatment method is simple, and the treatment cost is reduced.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] A treatment method for neutralizing wastewater in the production of 2-naphthol, wherein the neutralizing wastewater contains about 3-5 wt% of sodium sulfite, about 7-9 wt% of sodium sulfate and about 2-4 wt% of sodium 2-naphthalenesulfonate, COD It is 44000mg / L.

[0026] Treatment methods for this wastewater include:

[0027] (1) Acidification and separation: use sulfuric acid to adjust the pH value of the wastewater to 2.5-3, vacuumize to 250-300 mm Hg, heat to 80-90°C, stir and react until no sulfur dioxide gas is produced, and the generated sulfur dioxide gas returns to the Used in the acid analysis process of 2-naphthol production process;

[0028] (2), MVR evaporative concentration: the pH value of the waste water after acidification and separation is adjusted to 7.5-8, and MVR evaporative concentration is carried out to obtain evaporative condensed clear water and high-salt, high-concentration organic waste water with a salt content of about 50%, wherein evaporat...

Embodiment 2

[0031] A method for treating hydrolyzed waste water in J acid production. The hydrolyzed waste water contains 500-550 g / L of sulfuric acid, about 50-100 g / L of sodium sulfate, and about 35000 mg / L of CODcr.

[0032] Treatment methods for this wastewater include:

[0033] (1) MVR evaporation and concentration: adjust the pH value of the wastewater to 7.5-8 with liquid caustic soda, and carry out MVR evaporation and concentration to obtain evaporative condensed water and high-salt, high-concentration organic wastewater with a salt content of about 50%, and evaporated condensed water COD≤300mg / L, back to production;

[0034] (2) Oxidation and drying of spray oxidation tower: High-salt, high-concentration organic wastewater is oxidized and dried by spray oxidation tower, and it is specifically treated in sequence by pre-concentration section, solidification section, high-temperature carbonization section, and oxidation section. The temperature of the oxidation section is ≥1100 ° ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

| whiteness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com