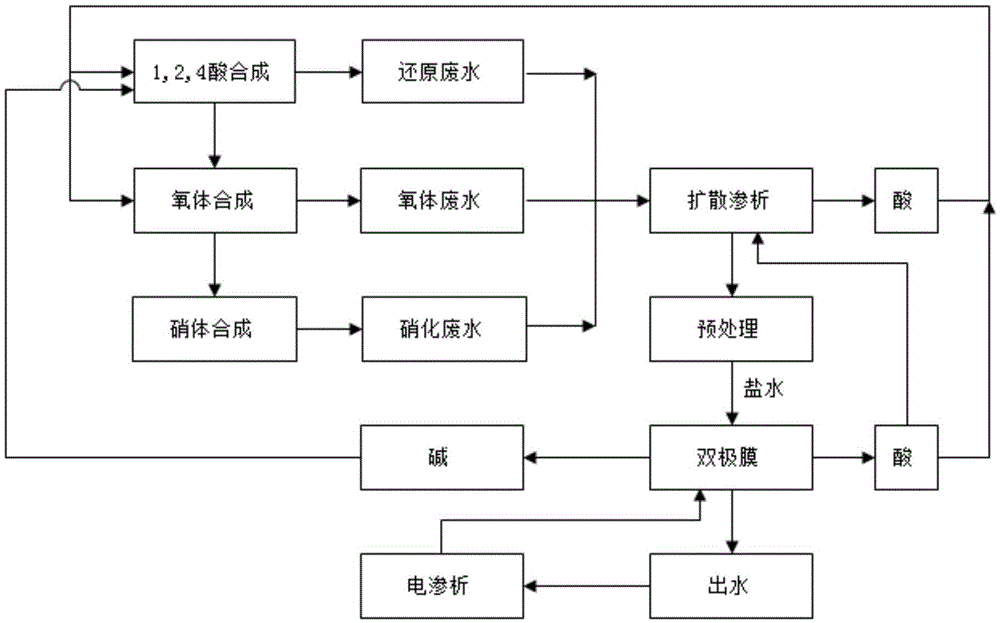

Improved 6-nitro-1-diazo-2-naphthol-4-sulphonic acid production process

A production process and acid oxide technology, which is applied in the production process field of 6-nitro-1,2,4 acid oxide, can solve the problems of difficult utilization, large area and complicated operation, and reduce the input cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0100] 6. The 1, 2, 4 acid wastewater produced in the production process of nitrate is black and red, with a COD of about 28790mg / L and a sulfuric acid content of 11%. The wastewater contains inorganic components such as sodium sulfate, sodium sulfite, and ferric sulfite.

[0101] (1) Acid recovery: After adding 0.4% activated carbon to the above waste water and stirring and adsorbing for 60 min, the COD of the filtrate obtained was about 17090 mg / L. Through the diffusion dialysis membrane, acid liquid and organic waste water are obtained. It is measured that the acid content in the acid solution is 10%, and the COD is about 20mg / L; the acid content in the organic wastewater is 1.1%, and the COD is about 18800mg / L.

[0102] (2) Organic wastewater treatment: the organic wastewater obtained in step (1) is heated to 60°C, and 0.2% FeSO is added 4 ·7H 2 O, uniformly add 11% hydrogen peroxide (the mass fraction of hydrogen peroxide is 28%) within 4 hours, stir while adding, and k...

Embodiment 2

[0105] In the 1,2,4 acid wastewater treatment method described in embodiment 1, step (1) is unchanged, and other steps are as follows:

[0106] Step (2): The organic wastewater obtained in step (1) is extracted, the extractant is trioctylamine, the diluent is sulfonated kerosene, the extractant and the diluent are mixed in a volume ratio of 1:4 to form an oil phase, and the oil-water ratio is 1:1, stirring and extracting for 30 minutes, separated by an oil-water separator, and the lower clear liquid was slightly yellow. Add liquid alkali to the lower layer to adjust the pH to 8, add 0.2% (based on the quality of the lower layer) activated carbon, stir and adsorb for 30 minutes, and filter to obtain the filtrate. The filtrate is almost colorless and transparent, its COD is 56mg / L, and it contains 11% sodium sulfate.

[0107] Step (3): The above-mentioned filtrate is concentrated by MVR to obtain sodium sulfate salt, which meets the industrial salt standard, and is recycled to ...

Embodiment 3

[0109] 6. The 1, 2, 4 acid oxygen body wastewater produced in the production process of nitrate is dark red, with a COD of about 16570mg / L, a sulfuric acid content of 15%, and about 3% of sodium sulfate and about 0.18% of copper in the wastewater.

[0110] (1) Add 0.2% activated carbon to the above waste water, stir and adsorb for 60 min, then filter, and the COD of the filtrate is about 14599 mg / L. The filtrate passes through the diffusion dialysis membrane to obtain acid liquid and organic waste water. The acid content in the acid solution was measured to be 14%, and the COD was about 47mg / L; the COD of the organic wastewater was measured to be about 15098mg / L.

[0111] (2) The organic wastewater obtained in step (1) is subjected to complex extraction, the oil-water ratio is 1:2 (volume ratio, mixed with 1:3 volume of trioctylamine and dichloroethane to form an oil phase, stirred at 50°C Extract for 1h, stand and separate to obtain the upper organic phase and the lower clea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com