Method for treating wastewater generated in production of 2-naphthol

A technology for producing wastewater and treatment methods, applied in water/sewage treatment, natural water treatment, extraction water/sewage treatment, etc., can solve the problems of high oxidant cost, technical difficulty, complicated process, etc., and achieve easy control, cost reduction, Simple to use effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

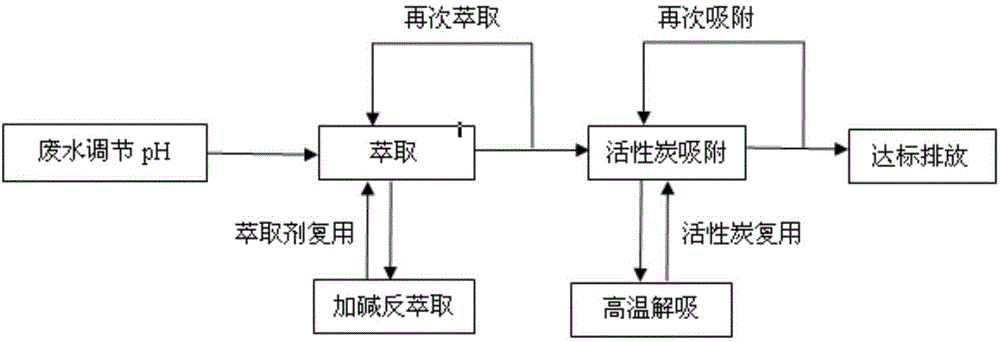

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] (1) Extraction process

[0031] Get TBP 7.5mL, n-octanol 7.5mL, hexanaphthene 35mL mix and be mixed with extraction agent, regulate the pH of waste water to 0.5 with dilute sulfuric acid, be 1: 1 with extraction agent (50mL) and waste water to be treated ( 50mL) together into a 250mL Erlenmeyer flask, oscillated and extracted at a constant speed on an air bath constant temperature oscillator (temperature 30°C, speed 150r / min) for 60min, then placed in a separatory funnel for phase separation for 30min.

[0032] (2) Activated carbon adsorption

[0033] Add 2.0 g of activated carbon to the raffinate, and vibrate at a constant speed for 1.5 h in a constant temperature shaker in a water bath (temperature 45° C., rotation speed 150 r / min).

[0034] (3) Stripping and desorption

[0035] Finally, after testing, the COD of wastewater was reduced from 11120mg / L to 480mg / L, and the removal rate reached 95.68%.

Embodiment 2

[0037] (1) Extraction process

[0038] Get TBP 7.5mL, n-octanol 10mL, hexanaphthene 32.5mL mix and be mixed with extraction agent, adjust the pH of waste water to 0.5 with dilute sulfuric acid, be 1:1.2 with extraction agent (50mL) and waste water to be treated ( 60mL) together into a 250mL Erlenmeyer flask, oscillated and extracted at a constant speed on an air bath constant temperature oscillator (30°C, 150r / min) for 60min, then placed in a separatory funnel for 30min to separate phases.

[0039] (2) Activated carbon adsorption

[0040] Add 2.0 g of activated carbon to the raffinate, and vibrate at a constant speed for 1.5 h in a constant temperature shaker in a water bath (temperature 45° C., rotation speed 150 r / min).

[0041] (3) Stripping and desorption

[0042] Finally, after testing, the COD of wastewater was reduced from 11120mg / L to 475mg / L, and the removal rate reached 95.73%.

Embodiment 3

[0044] (1) Extraction process

[0045]Get TBP 10mL, n-octanol 10mL, cyclohexane 30mL and mix and prepare extractant, adjust the pH of waste water to 0.5 with sulfuric acid, be 1: 1 by oil-water volume ratio, extractant (50mL) and waste water to be treated (50mL) together Put it into a 250mL Erlenmeyer flask, shake and extract at a constant speed for 60min on an air bath constant temperature oscillator (temperature: 35°C, speed: 150r / min), then place it in a separatory funnel for phase separation for 30min.

[0046] (2) Activated carbon adsorption

[0047] Add 2.0 g of activated carbon to the raffinate, and shake at a constant speed for 1.5 h in a constant temperature shaker in a water bath (temperature 45° C., rotation speed 200 r / min).

[0048] (3) Stripping and desorption

[0049] Finally, after testing, the COD of wastewater was reduced from 11120mg / L to 440mg / L, and the removal rate reached 96.04%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Removal rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com