Selective oxidative light catalyst and preparing method thereof

A photocatalyst, selective technology, applied in physical/chemical process catalysts, chemical instruments and methods, organic compound/hydride/coordination complex catalysts, etc., to achieve the effect of increasing efficiency, high selectivity, and reducing reaction costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

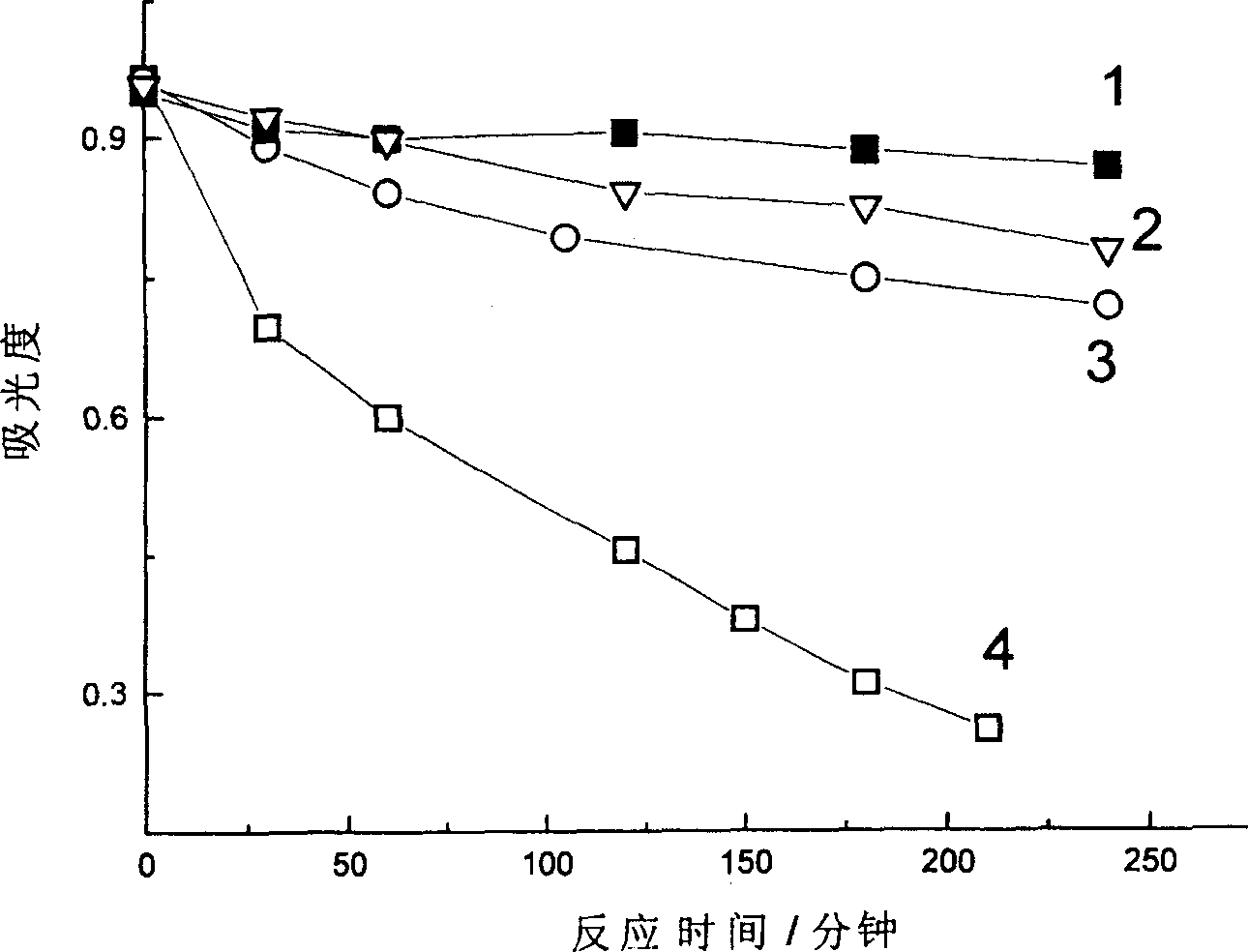

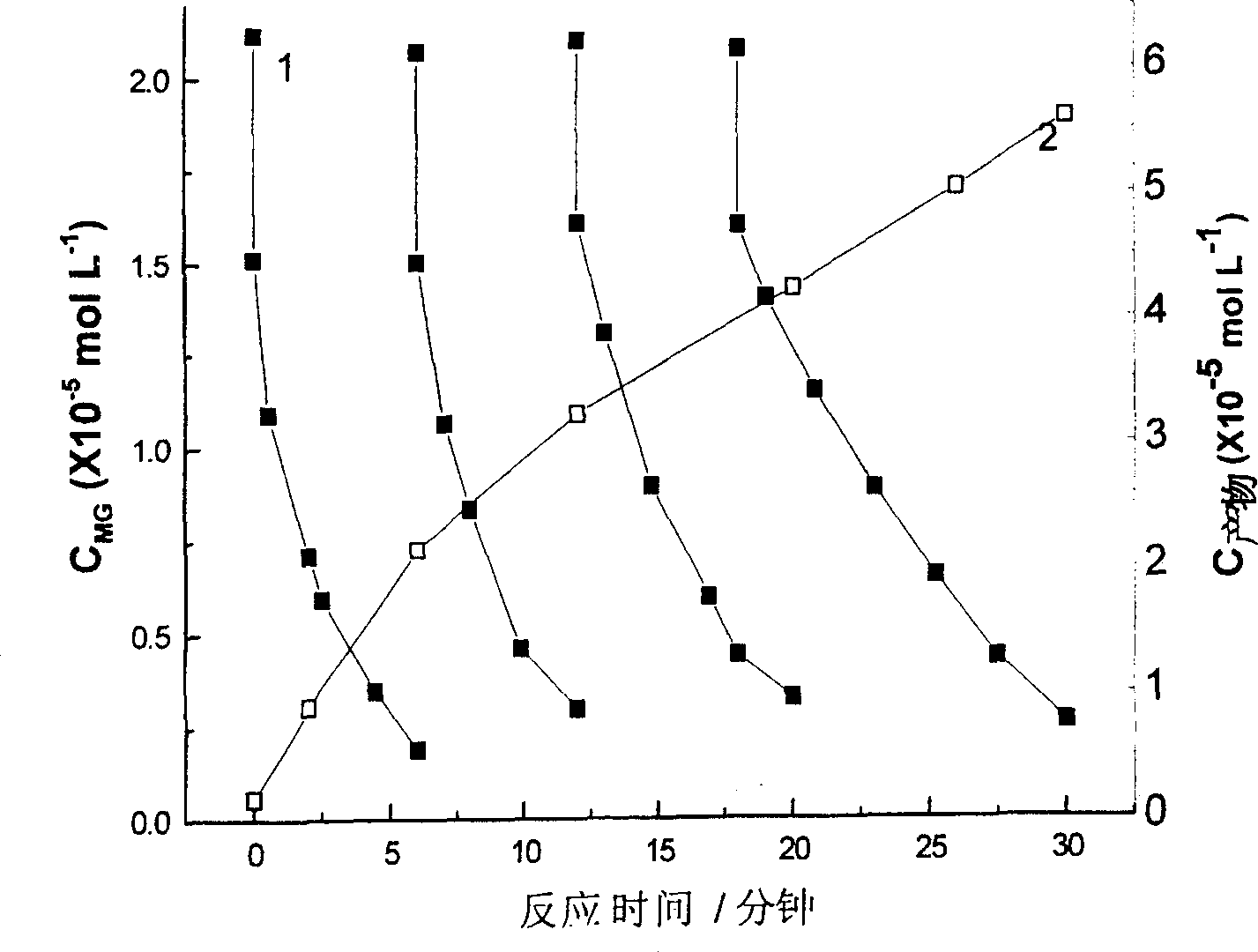

Image

Examples

Embodiment 1

[0041] Get selected 10 grams of molecular sieves, join in the reactor after pretreatment, ferric dichloride (FeCl 2 4H 2 O) dubbed 2×10 -3 The aqueous solution of M was 0.5 liters, stirred for more than 5 hours to fully load the metal ions. Continue to wash with water without iron ions and dry for later use. Mix 2 g of α, α'-bipyridine with the prepared molecular sieve, grind it thoroughly, place it in a closed container, and heat it to 90° C. in a tube furnace for 24 hours to react. Wrap the obtained crude product with filter paper, and use CH 2 Cl 2 As a solvent, use a Soxhlet extractor to remove excess ligands, heat and dry at 50°C under nitrogen protection before use.

Embodiment 2

[0043] Prepare 10 grams of molecular sieves loaded with ferrous iron with Example 1, and take by weighing 1,10-phenanthroline (C 12 h 8 N 2 ·H 2 (0) 3 grams, mixed evenly, placed in a closed container, heated to 90°C in a tube furnace to react for 24 hours. Wrap the prepared crude product with filter paper, use acetone as a solvent, remove excess ligands with a Soxhlet extractor, heat and dry at 50°C under nitrogen protection, and then use it.

Embodiment 3

[0045] 10 grams of ferrous iron-loaded molecular sieves were prepared in the same manner as in Example 1, and 2 grams of Schiff bases were weighed, mixed evenly, placed in a closed container, and heated to 90° C. in a tube furnace for 24 hours to react. Wrap the obtained crude product with filter paper, and use CH 2 Cl 2 As a solvent, use a Soxhlet extractor to remove excess ligands, heat and dry at 50°C under nitrogen protection before use.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com