Preparation method for synthetizing high efficiency water reducing agent by 2-naphthol waste water

A high-efficiency water-reducing agent and naphthol technology, which is applied in the field of preparation of 2-naphthol wastewater synthesizing high-efficiency water-reducing agent, can solve the problem of not seen synthetic high-efficiency water-reducing agent in naphthol wastewater, human and environmental hazards, and high wastewater concentration problems, to achieve the effect of good economic value and social benefits, good dispersion ability, and simple production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] The preparation method of 2-naphthol wastewater synthesis high-efficiency water reducer, put 500g of industrial naphthalene into a four-necked flask with stirring, add 460g of 98% concentrated sulfuric acid dropwise when heated to 140°C, and Keep warm for 2.5 hours under the same conditions, add 220g of 2-naphthol wastewater when the temperature drops to 100°C, hydrolyze for 1 hour, add 37% formaldehyde solution dropwise at 95°C-105°C and keep warm for 5 hours. Cool to room temperature and add 32% liquid caustic soda to neutralize to pH 8 to obtain the final product high-efficiency water reducer.

Embodiment 2

[0029] The preparation method of 2-naphthol wastewater synthesis high-efficiency water reducer, put 500g of industrial naphthalene into a four-necked flask with stirring, add 500g of 98% concentrated sulfuric acid dropwise when heated to 140°C, and heat it at 160°C-165°C Keep warm for 2 hours under the same conditions. When the temperature drops to 100°C, add 200g of 2-naphthol wastewater, hydrolyze for 0.5 hours, keep warm at 95°C-105°C, add dropwise 37% formaldehyde solution and keep warm for 4 hours. Cool to room temperature and add 32% liquid caustic soda to neutralize to pH 8 to obtain the final product high-efficiency water reducer.

Embodiment 3

[0031] The preparation method of 2-naphthol wastewater synthesis high-efficiency water reducer, put 500g of industrial naphthalene into a four-necked flask with stirring, add 500g of 98% concentrated sulfuric acid dropwise when heated to 140°C, and heat it at 160°C-165°C Keep warm for 2 hours under the same conditions, when the temperature drops to 100°C, add 100g of water and 100g of 2-naphthol wastewater, hydrolyze for 0.5 hours, keep warm at 95°C-105°C, add dropwise 37% formaldehyde solution and keep warm for 5 hours, after the condensation is completed , cooling it to room temperature and adding 32% liquid caustic soda to neutralize to pH 8 to obtain the final product high-efficiency water reducer.

[0032] Implementation Effect

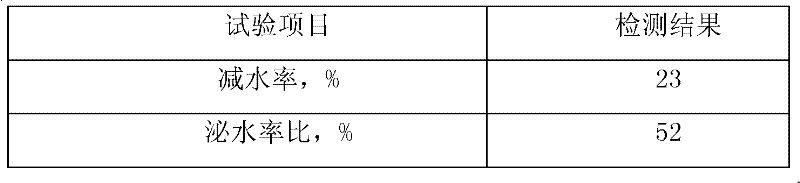

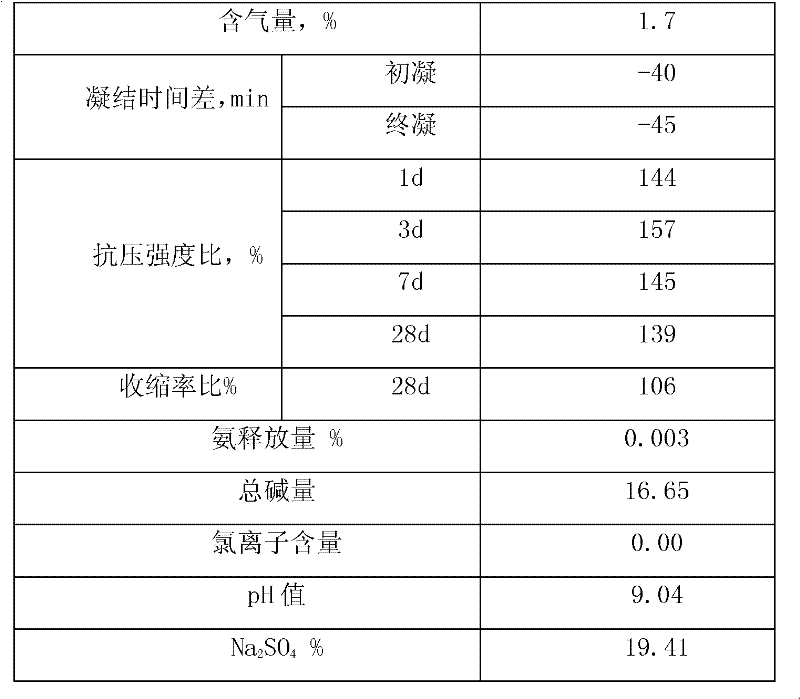

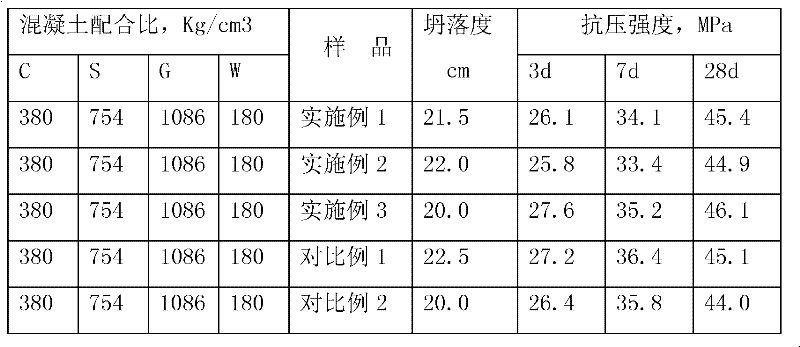

[0033] Table 1. The following is the performance status of the present invention and various performance comparisons with other similar products

[0034]

[0035]

[0036] Table 1 is the performance index of the water reducer prepared by t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com