Method and equipment for extracting potassium salt from sintering machine head electroprecipitating dust in metallurgical industry

An electrostatic precipitator and potassium salt technology, which is applied in the purification of alkali metal sulfite/sulfate and alkali metal halide, etc., can solve problems such as adverse effects, and achieve less impurity metal elements, simple structure, and efficient extraction. and separate effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

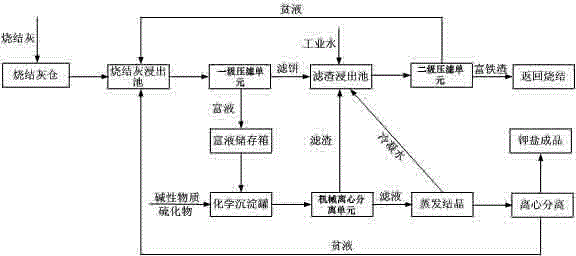

[0028] The present invention will be further described below in conjunction with the accompanying drawings.

[0029] The invention discloses a method for extracting potassium salt from electric dust of sintering head in the metallurgical industry, the steps comprising: stirring and leaching, chemical precipitation, mechanical centrifugal separation and evaporation crystallization.

[0030] The stirring and leaching step comprises:

[0031] (1) Add industrial water and leach the sintered ash under stirring conditions. After the leaching is completed, the formed suspension is sent to the first-stage filter press unit for solid-liquid separation; The rich solution enters the rich solution storage tank, while the filter cake enters the filter residue leaching tank for releaching;

[0032] (2) After the filter cake is stirred and leached in the filter residue leaching tank, it is pumped to the secondary filter press unit for filtration, and the resulting filter residue is dried a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com