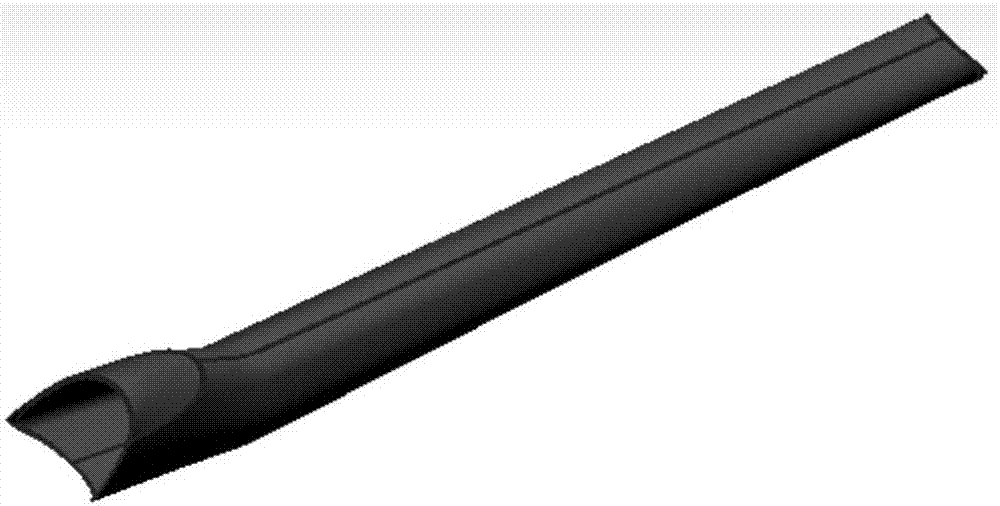

Forming method and application of a thin-walled titanium alloy pipe with complex variable cross-section

A titanium alloy and variable cross-section technology, applied in the field of material processing, can solve problems such as uneven wall thickness distribution, cumbersome process control, and difficulty in mass production, and achieve reliable process technology assurance, high dimensional accuracy, and high dimensional accuracy. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] This embodiment provides a method for superplastic inflatable forming of a thin-walled titanium alloy complex variable-section pipe. The specific steps are as follows:

[0045] 1) Weld a head with an air inlet channel at one end of the pipe;

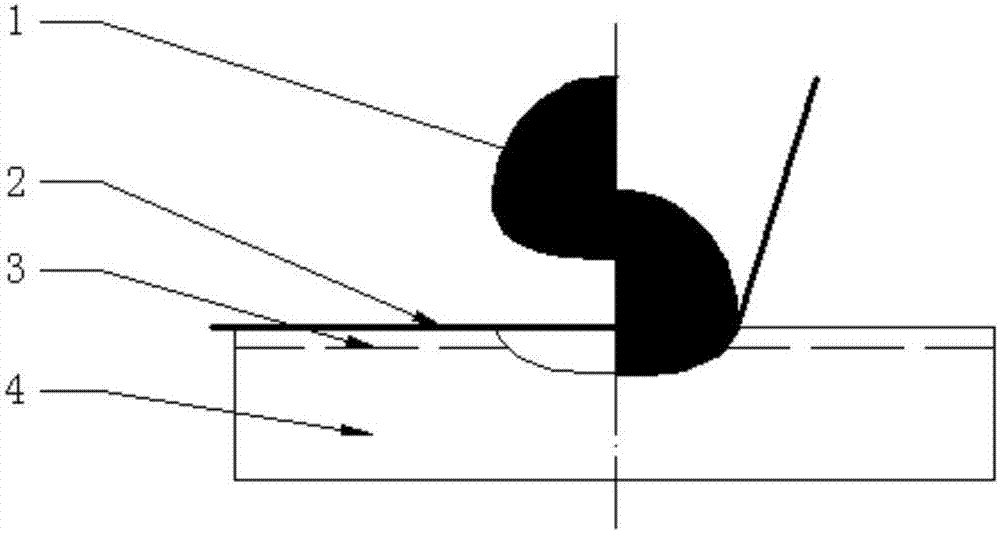

[0046] 2) Spray solder resist on the parts where the die and punch are in contact with the pipe; place the pipe with the air intake channel in the cavity of the die, and close the molds;

[0047] 3) Introduce high-purity argon gas into the mold and pipe, vacuumize, and repeat 3 times to discharge the gas inside the mold and pipe;

[0048] 4) Heat to the superplastic forming process temperature (usually 950°C), keep it warm for 1 hour to ensure that the temperature of the mold and the pipe is uniform, and slowly introduce high-purity argon into the pipe through the air inlet channel to control the strain rate during the deformation of the pipe. 5×10 -4 / s, the forming time is about 3 hours, the pressure is unloaded, and the tempe...

Embodiment 2

[0054] This embodiment provides a method for forming a thin-walled titanium alloy pipe with complex variable cross-section, and the specific steps are as follows:

[0055] 1) Cut the titanium alloy plate according to the expanded size of the variable cross-section special-shaped pipe to obtain the special-shaped titanium plate. The wall thickness of the titanium plate used is 0.2mm, and the material is TC4 titanium alloy;

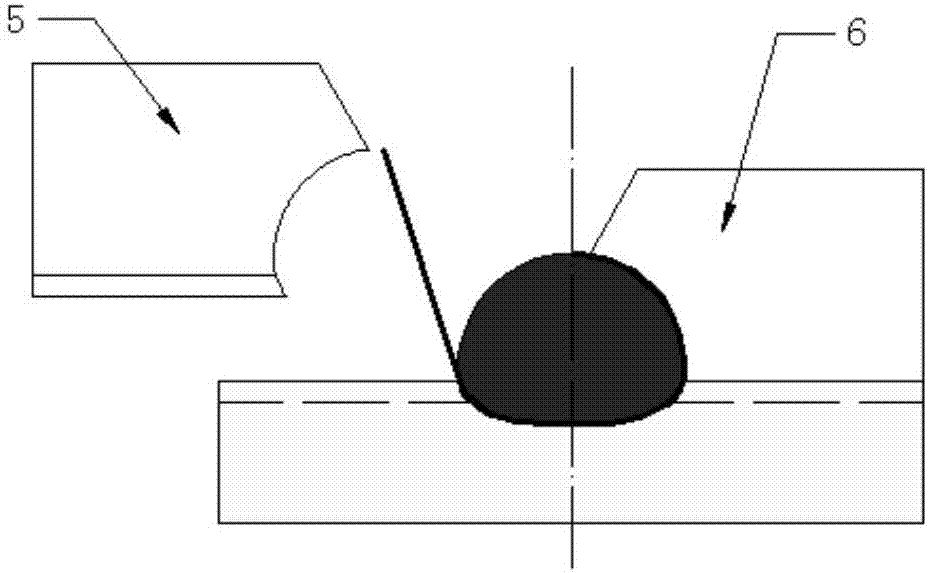

[0056] 2) Spray solder resist at the position where the die, mandrel, upper die, left and right dies are in contact with the pipe; the die is a cavity with the same shape as the outside of the complex variable cross-section pipe; The mold with the same inner shape of the cross-section pipe; the upper mold is a mold with the same curvature as the weld position of the complex variable cross-section pipe; the left and right molds are molds that form the outer shape of the complex variable cross-section pipe surrounded by the die.

[0057] 3) Place the special-...

Embodiment 3

[0063] This embodiment provides a method for forming a thin-walled titanium alloy pipe with complex variable cross-section, and the specific steps are as follows:

[0064] This embodiment provides a method for forming a thin-walled titanium alloy pipe with complex variable cross-section, and the specific steps are as follows:

[0065] 1) Cut the titanium alloy plate according to the expanded size of the variable cross-section special-shaped pipe to obtain the special-shaped titanium plate. The wall thickness of the titanium plate used is 0.5mm, and the material is Ti55 titanium alloy;

[0066] 2) Spray solder resist at the position where the die, mandrel, upper die, left and right dies are in contact with the pipe; the die is a cavity with the same shape as the outside of the complex variable cross-section pipe; The mold with the same inner shape of the cross-section pipe; the upper mold is a mold with the same curvature as the weld position of the complex variable cross-secti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com