Assembled parking lot and paving method thereof

A parking lot, prefabricated technology, applied in the parking lot field, can solve the problems of low cost, short construction period, and difficulty in standardizing parking in urban idle vacant land, so as to achieve the effect of reducing construction waste, low cost, and solving long-term maintenance and management problems.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

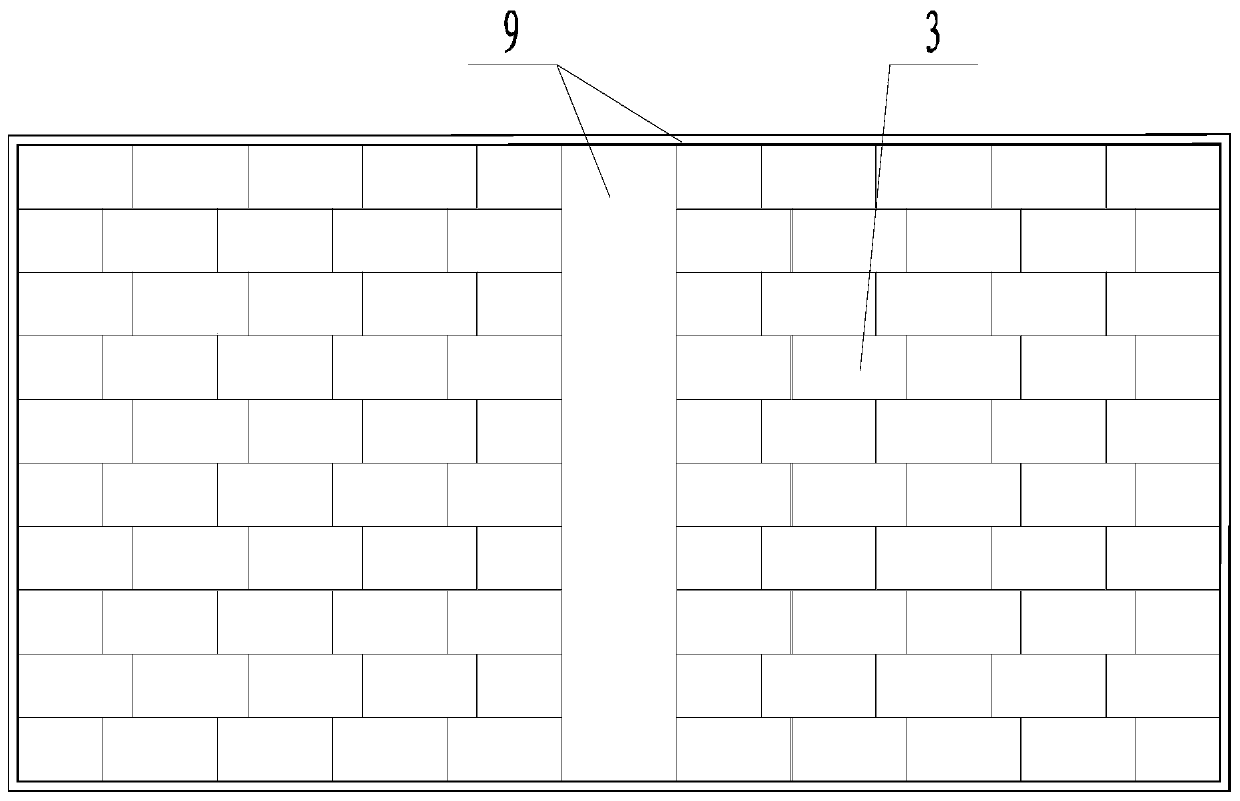

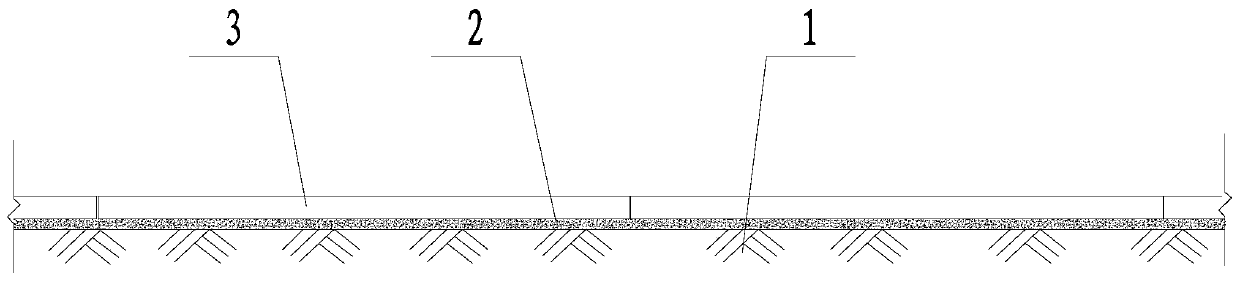

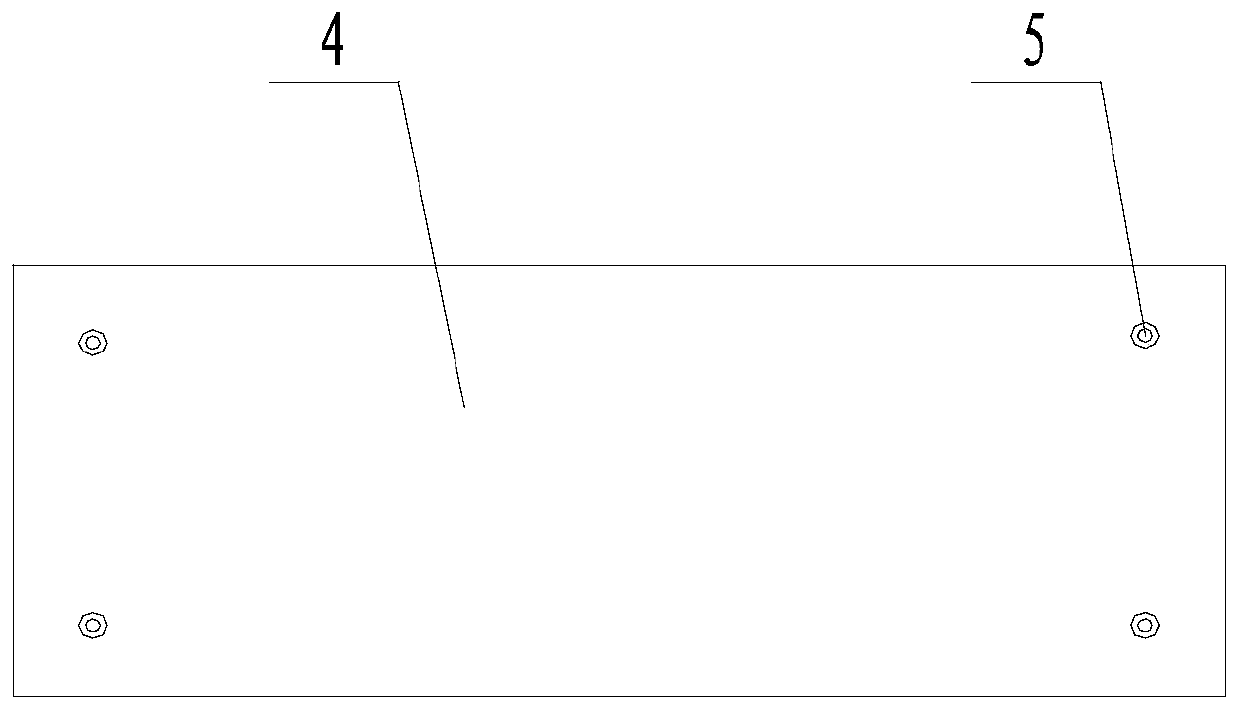

[0038] Such as Figure 1 to Figure 4 A prefabricated parking lot shown includes a plain soil layer 1, a leveling layer 2 on the plain soil layer 1, a parking lot prefabricated panel group 3 laid on the leveling layer 2, and the parking lot prefabricated panel group 3 is formed by laying several adjacent prefabricated facing bricks. The prefabricated facing bricks include a precast concrete slab 4, a sleeve 5 inside the precast concrete slab 4, and an anti-drawing steel plate 6 fixedly sleeved outside the sleeve 5. Pulling steel plate 6 is located in prefabricated concrete slab 4. The prefabricated facing bricks are square, and sleeves 5 are arranged at four corners of the prefabricated facing bricks. The bottom end of the sleeve 5 is flush with the bottom surface of the precast concrete slab 4, the sleeve 5 is provided with an internal thread, and also includes a screw 15 threaded in the sleeve 5, and the top end of the screw 15 is fixedly connected to the cover plate 7 . A...

Embodiment 2

[0042] Such as Figure 1 to Figure 5 The shown prefabricated parking lot, on the basis of Embodiment 1, also includes a prefabricated lawn 9 located at the edge of the prefabricated slab group 3 in the parking lot and / or between the prefabricated slab groups 3 in the adjacent parking lot. The prefabricated lawn 9 includes a plain soil layer 1 , a gravel layer 10 , and a prefabricated lawn slab 11 distributed sequentially from bottom to top, and artificial turf 12 is laid on the prefabricated lawn slab 11 . Several prefabricated drainage ditches 13 are arranged in the prefabricated lawn 9 , the bottom ends of the prefabricated drainage ditches 13 are connected to the plain soil layer 1 , and the tops of the prefabricated drainage ditches 13 are detachably connected to the prefabricated ditch cover plate 14 .

[0043] The paving method of the prefabricated lawn ground 9 is:

[0044] Sa, tamp the plain soil layer 1, and insert some prefabricated drainage ditches 13 into the plai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com