An optical-mechanical-electric-hydraulic integrated flexible manufacturing system

A flexible manufacturing system, electrical technology, applied in educational appliances, instruments, teaching models, etc., can solve problems such as shortage of teaching equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to have a further understanding and understanding of the structural features of the present invention and the achieved effects, the preferred embodiments and accompanying drawings are used for a detailed description, as follows:

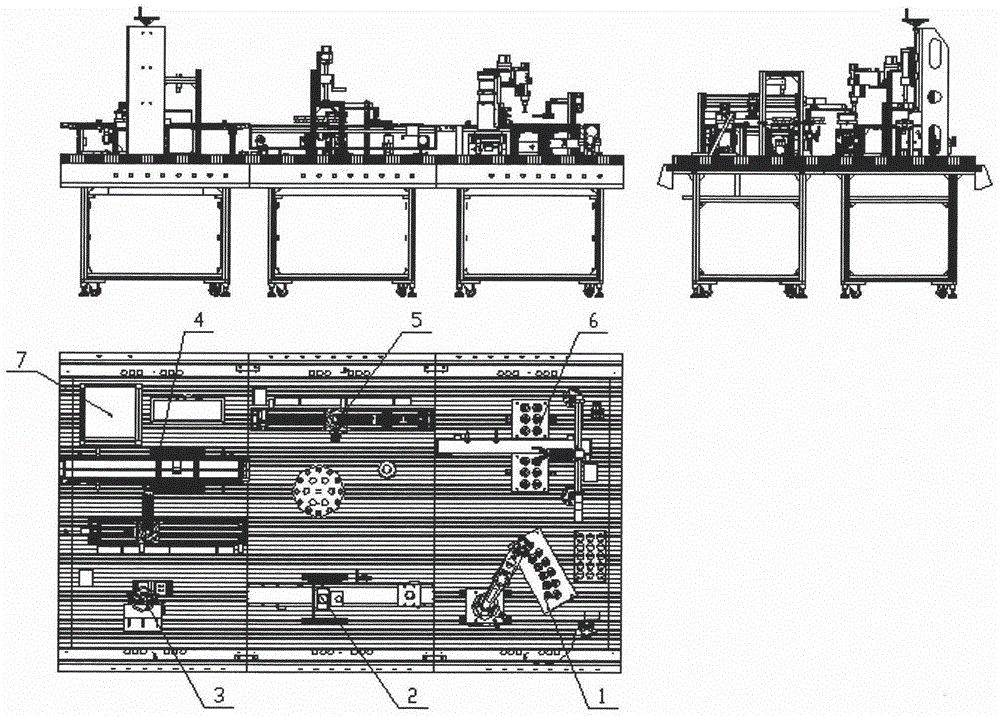

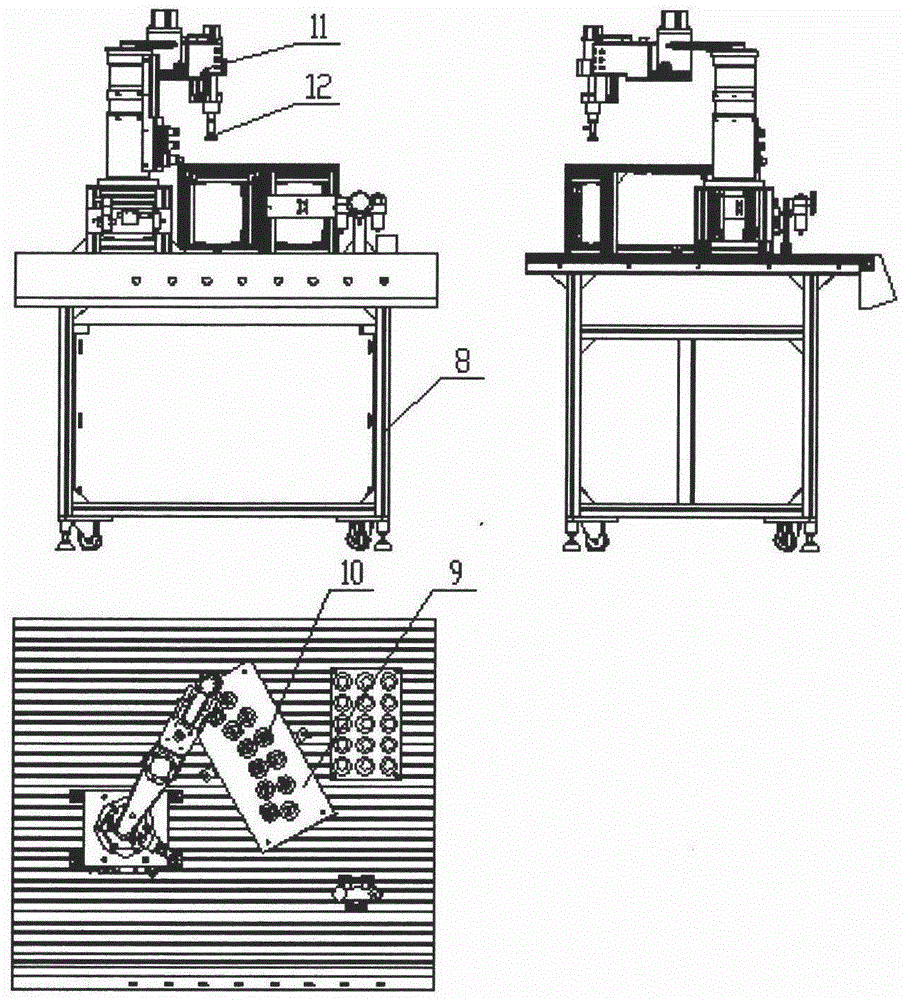

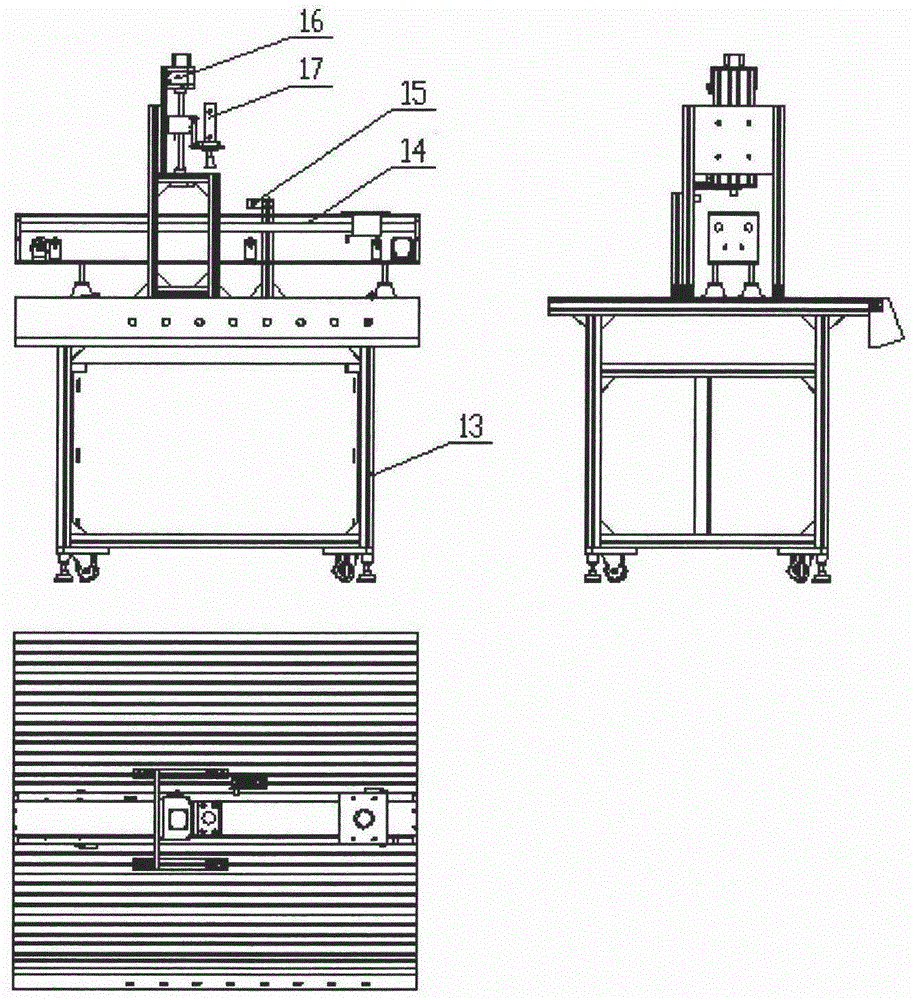

[0024] Such as figure 1 The optical-mechanical-electric-hydraulic integrated flexible manufacturing system consists of a four-degree-of-freedom SCARA robot outbound unit 1, a hydraulic stamping unit 2, a hydraulic processing unit 3, a CCD color recognition unit 4, an automatic assembly unit 5, and an automatic classification storage unit 6 It is composed of a computer master control system 7 and a pneumatic system. The system is equipped with a master control computer, and the unit has stand-alone / online functions. The aluminum alloy desktop of each unit can operate independently from the system, and all stand-alone devices in the system can be highly and efficiently integrated through the industrial ProfiBus-DP bus. The six groups o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com