Process and device for treating phenol-containing wastewater

A technology for treating phenolic wastewater, which is applied in the field of phenolic wastewater treatment and equipment, can solve the problems of difficult operation of the evaporation system, large amount of regeneration agent used, and short service life of the extractant, etc., to improve biodegradability, The effect of reducing investment costs and reducing salt production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further illustrated below in conjunction with the accompanying drawings and specific embodiments. It should be understood that these embodiments are only used to illustrate the present invention and are not intended to limit the scope of the present invention. After reading the present invention, those skilled in the art all fall into the appended claims of the present application to the amendments of various equivalent forms of the present invention limited range.

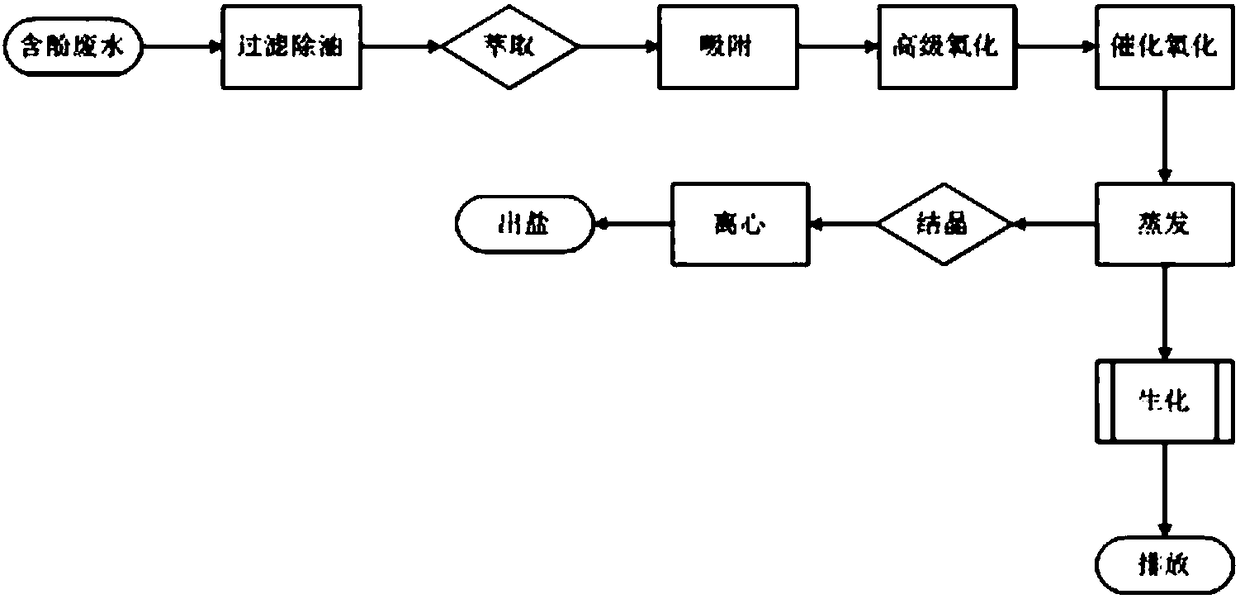

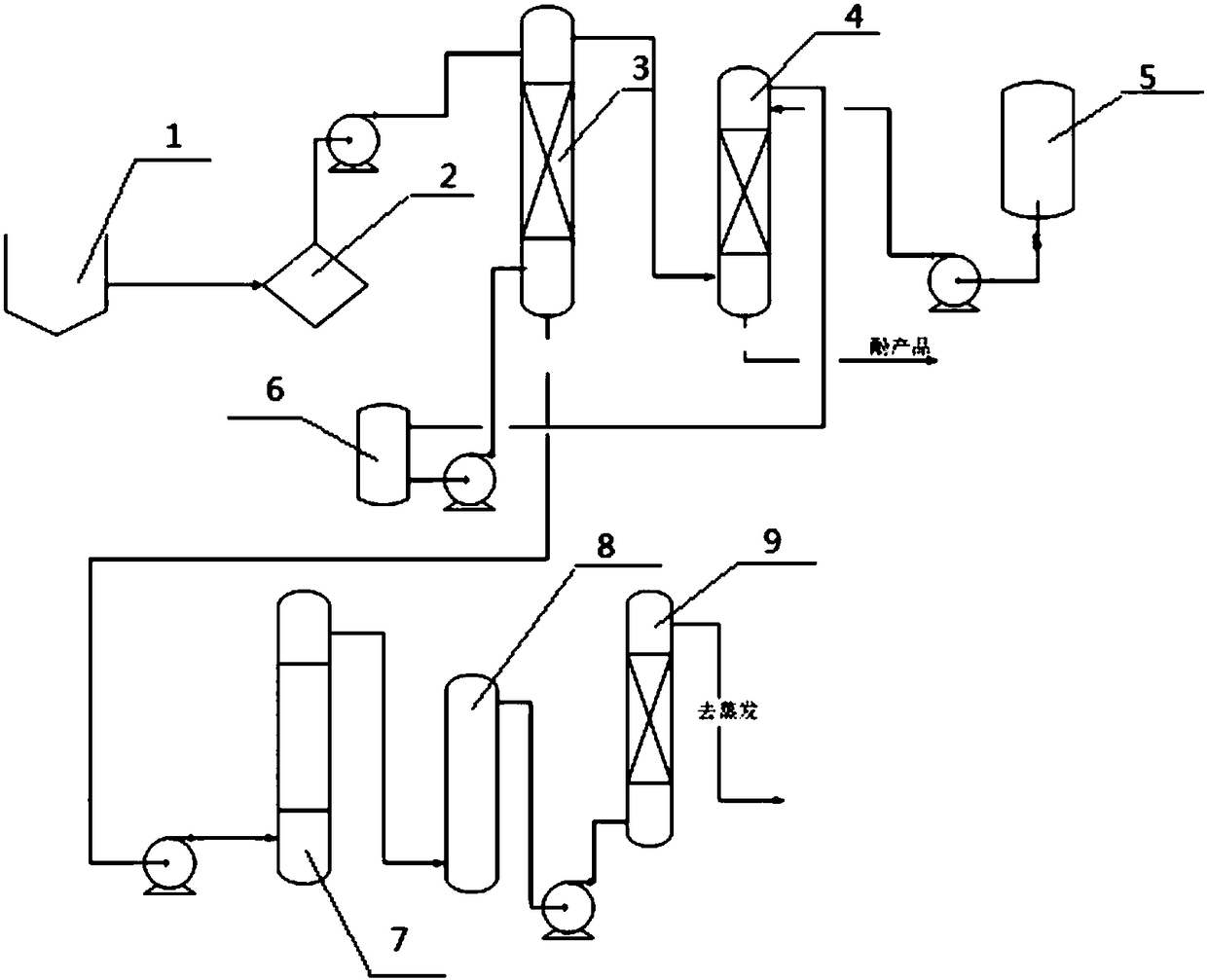

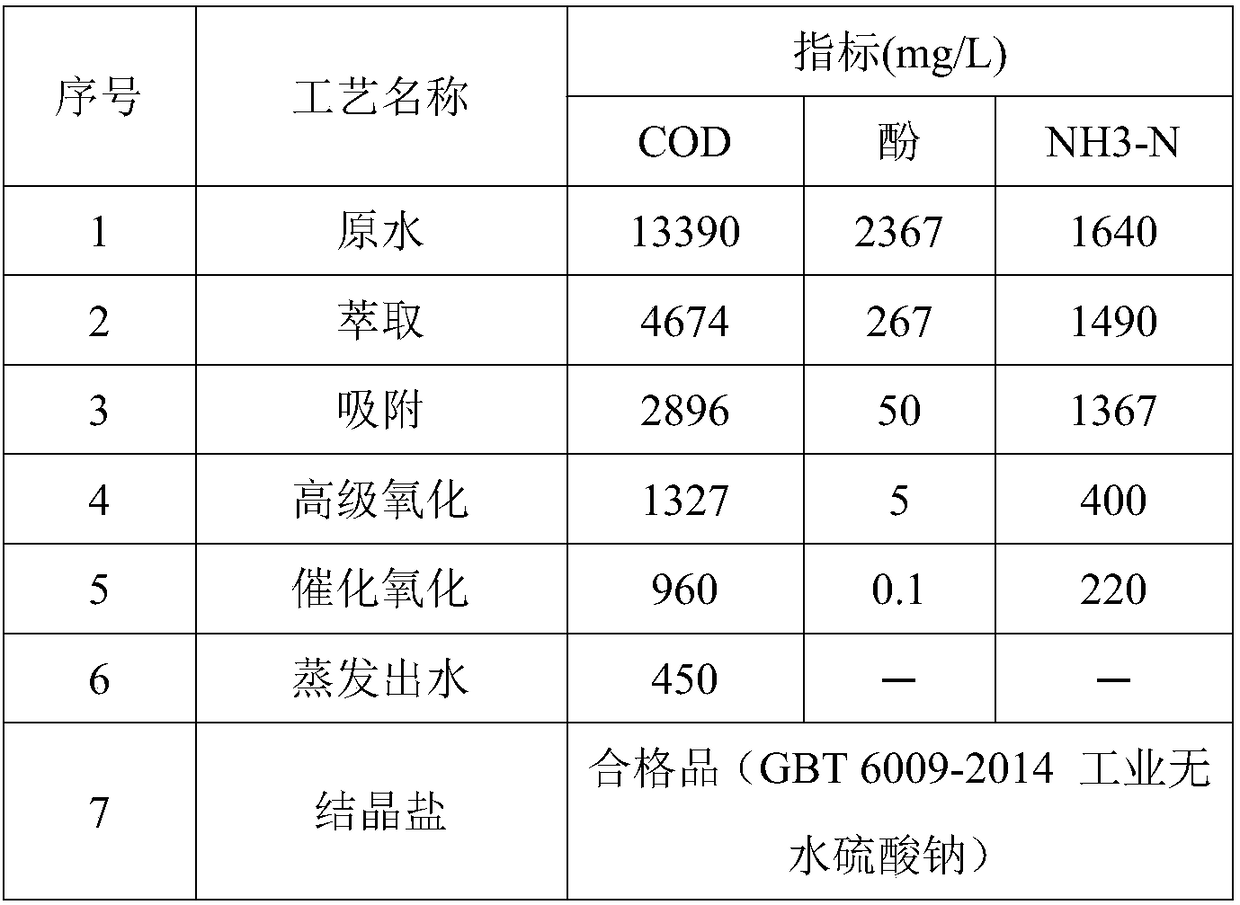

[0031] Such as figure 1 with 2 Shown, the treatment process method of phenolic waste water of the present invention comprises:

[0032] 1: The filtration and degreasing system uses nanofiltration membrane (ceramic\organic material) to remove tar substances in the phenolic sodium salt wastewater, slowing down the damage to the extraction agent and filler in the subsequent extraction process and adsorption process in the wastewater, and prolonging the extraction time of the ext...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com