Production method for increasing nitrate removal capacity by membrane method

A production method, membrane denitrification technology, applied in alkali metal sulfite/sulfate purification, alkali metal chloride, etc., to achieve the effect of simple daily operation, stable and efficient operation of the device, high operating rate and load rate of the device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

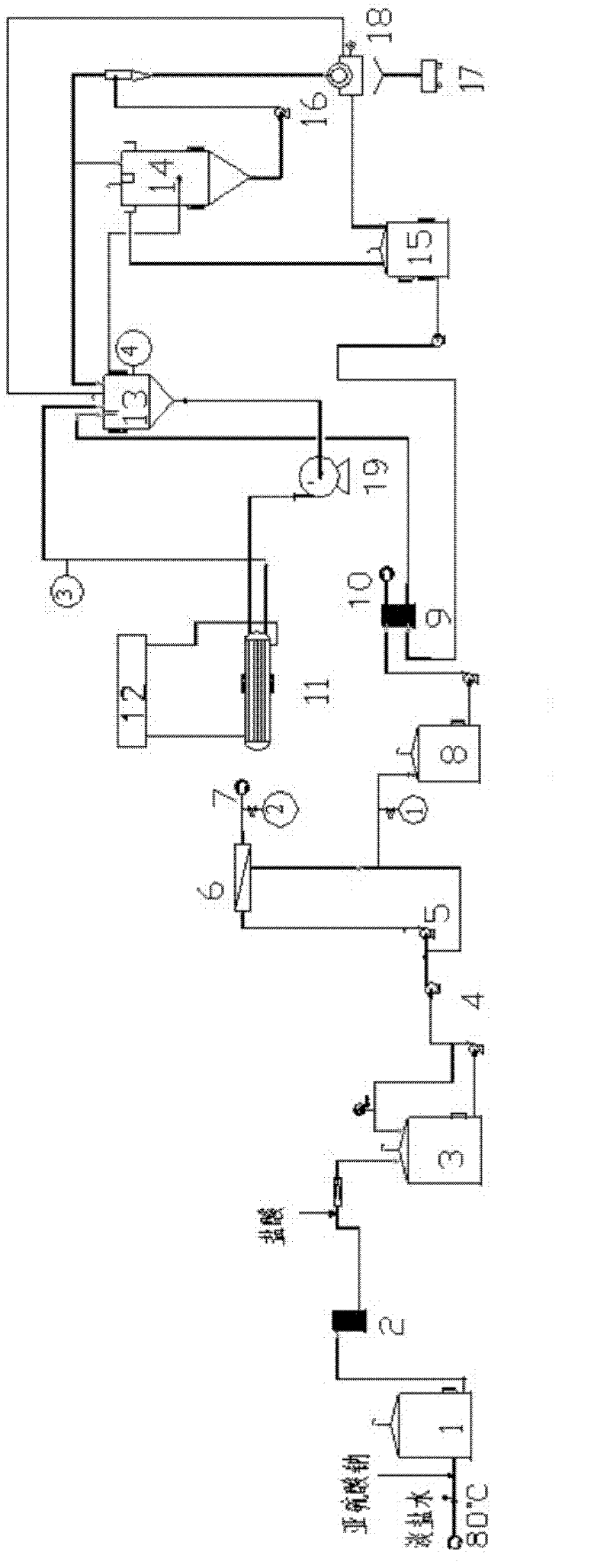

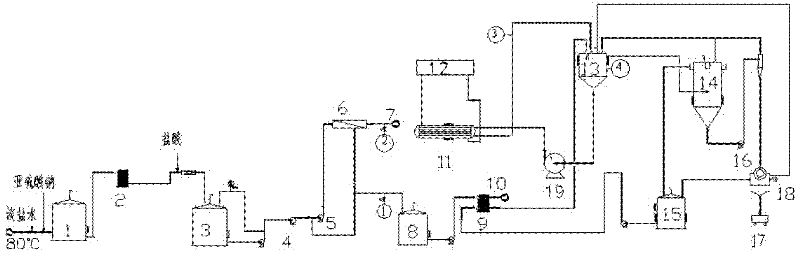

Method used

Image

Examples

Embodiment 1

[0033] In the embodiment, the raw material adopts light brine from the ionic membrane of the brine electrolytic dechlorination section, the content of sodium chloride is 200g / L, and about 10g / L of sodium sulfate is obtained by an integrated internal circulation nanofiltration membrane device (Hangzhou Kaijie Membrane Separation Technology Co., Ltd. ) membrane separation and concentration to about 46g / L, and enter the refrigerator (Hangzhou Kaijie Membrane Separation Technology Co., Ltd). The method consists of three parts: pretreatment, membrane separation and freezing unit. The details are as follows:

[0034] The light brine from the brine electrolytic dechlorination section is pretreated to meet the membrane entry conditions and then enters the integrated internal circulation nanofiltration membrane device for filtering sodium sulfate for membrane separation. The water separated by the membrane is divided into two streams, one of which is less than 3g / l The depleted nitrat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com