Nanofiltration membrane blending based high salinity wastewater zero discharge processing method and device

A technology of high-salt wastewater and treatment device, applied in the field of water treatment, can solve problems such as the enrichment of salt-containing wastewater, and achieve the effects of reducing the amount of mother liquor, wide adaptability, and realizing resource utilization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

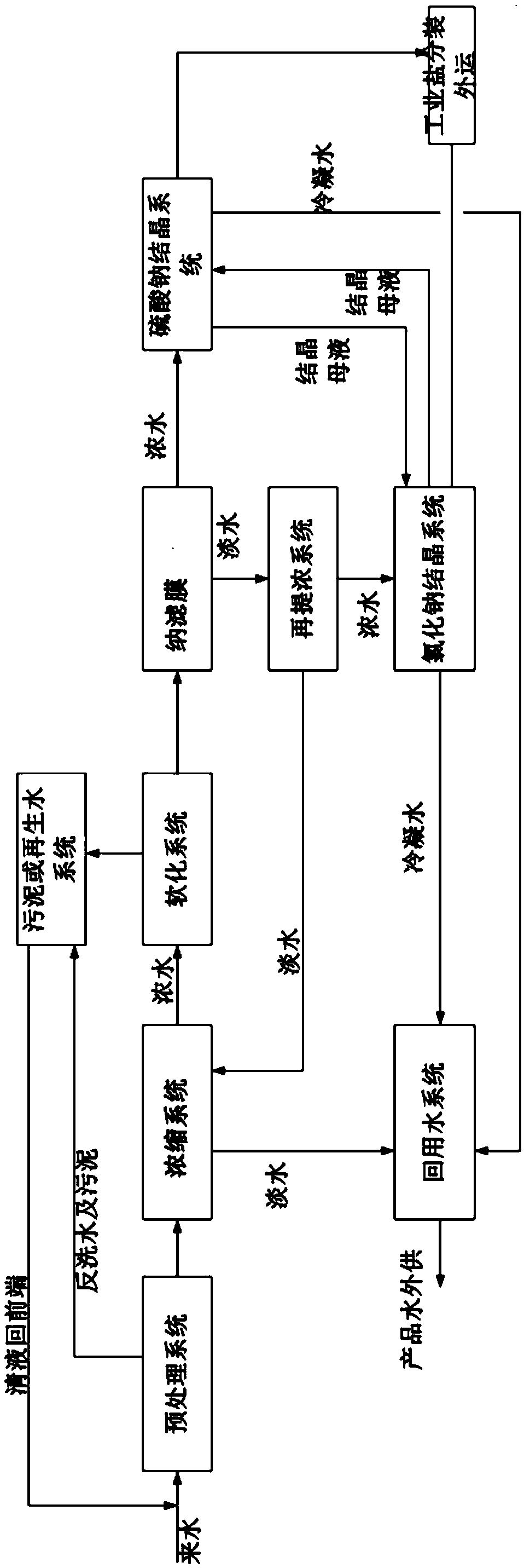

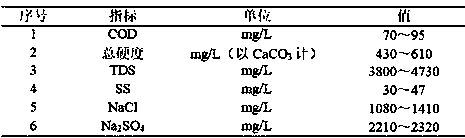

[0088] For a certain pulping wastewater, nanofiltration and crystallization cogeneration process was adopted to realize zero discharge of wastewater and recovery and reuse of industrial salt. The daily treatment capacity of pulping wastewater raw water is 40,000 tons. The main water quality parameters are shown in the table below:

[0089]

[0090] The raw water of pulping wastewater is homogenized by the homogenization tank, and then the incoming water is pretreated by sand filtration, ozone and activated carbon biological filter process. The ozone concentration is 150ppm, the ozone oxidation time is 40min; the hydraulic retention time is 15min; the carbon bed height of the activated carbon biological filter 2.0m, treatment temperature 25-30°C, empty bed contact time 20min; after pretreatment, the SS of wastewater is reduced to 12-18mg / L, the concentration of COD is reduced to 45-53mg / L, and the recovery rate of pretreated water is greater than 97%.

[0091] The pretreate...

Embodiment 2

[0098] A coal chemical company currently has a sewage treatment station with a wastewater discharge of 2750m 3 / h, the wastewater can meet the standard discharge requirements. The discharge water quality indicators are as follows:

[0099]

[0100] Inorganic salts in wastewater are mainly sodium chloride and sodium sulfate. Adopt nanofiltration and crystallization co-production process to treat wastewater with zero discharge.

[0101] Coal chemical wastewater is transported from the factory area to the zero-discharge raw water. After being homogenized in the homogenization tank, the incoming water is pretreated by sand filtration, ozone, and activated carbon adsorption processes. The ozone concentration is 200ppm, and the ozone oxidation time is 50 minutes; the activated carbon adsorption temperature is 20°C, and the hydraulic retention The time is 12 minutes; after pretreatment, the SS of wastewater is reduced to 5-9mg / L, the concentration of COD is reduced to 20-31mg / L,...

Embodiment 3

[0110] For a certain pulping wastewater, nanofiltration and crystallization cogeneration process was adopted to realize zero discharge of wastewater and recovery and reuse of industrial salt. The daily treatment capacity of pulping wastewater raw water is 40,000 tons. The main water quality parameters are shown in the table below:

[0111]

[0112] The raw water of pulping wastewater is homogenized by the homogenization tank, and then the incoming water is pretreated by sand filtration, ozone and activated carbon biological filter process. The ozone concentration is 150ppm, the ozone oxidation time is 40min; the hydraulic retention time is 15min; the carbon bed height of the activated carbon biological filter 2.0m, treatment temperature 25-30°C, empty bed contact time 20min; after pretreatment, the SS of wastewater is reduced to 12-18mg / L, the concentration of COD is reduced to 45-53mg / L, and the recovery rate of pretreated water is greater than 97%.

[0113] The pretreate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Hardness | aaaaa | aaaaa |

| Hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com