Treatment method and treatment system for ternary positive electrode material production wastewater

A cathode material, a technology for producing wastewater, which is applied in the fields of water/sewage multi-stage treatment, heating water/sewage treatment, water/sludge/sewage treatment, etc. The effect of high water recovery rate and simple method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

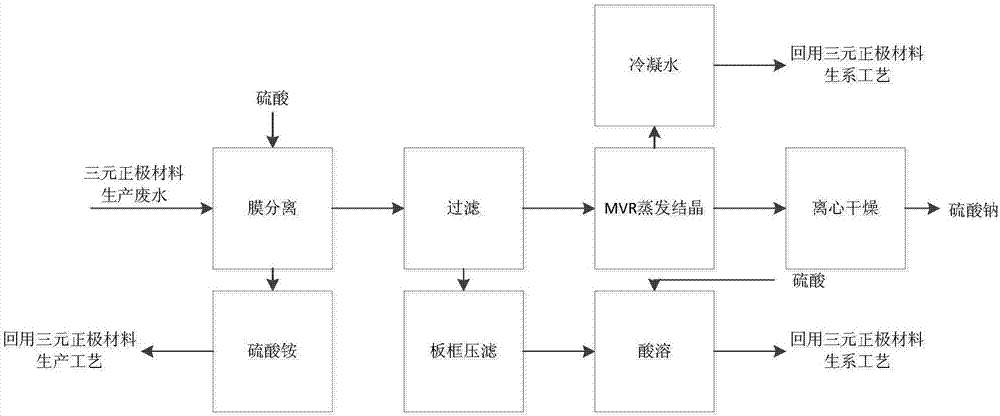

Method used

Image

Examples

Embodiment 1

[0070] Taking a domestic ternary precursor manufacturer with an annual output of 6,000 tons as an example, the wastewater volume is 350m 3 / d. The pollutant concentration test of wastewater discharge is as follows:

[0071] Pollutants pH Na 2 SO 4

NH 3 -N

M 2+

Concentration(g / L) 12.95 100 10.2 0.243

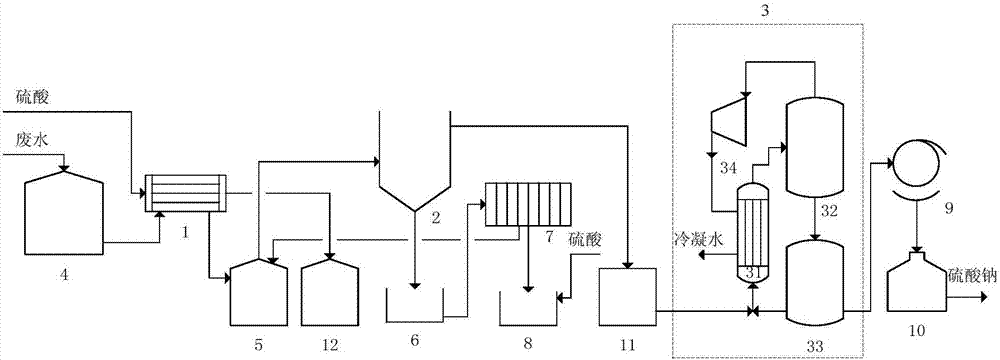

[0072] A treatment system for waste water produced by ternary cathode materials, such as figure 2 As shown, it includes: a membrane separation device 1, which is used to perform membrane separation on the production wastewater of the ternary positive electrode material to obtain deamination wastewater; Inlet, the shell side outlet for discharging the deammonization waste water out of the membrane separation device, the tube side inlet for entering the sulfuric acid into the membrane separation device and the tube side outlet for discharging the ammonium sulfate solution out of the membrane separation device, the membrane separation de...

Embodiment 2

[0080] Taking a domestic ternary precursor manufacturer with an annual output of 10,000 tons as an example, the wastewater volume is 1,000m 3 / d. The pollutant concentration test of wastewater discharge is as follows:

[0081] Pollutants pH Na 2 SO 4

NH 3 -N

M 2+

Concentration(g / L) 11.5 75 4.5 0.07

[0082] For a schematic diagram of the process, see figure 2 . In the figure, the membrane is separated into polytetrafluoroethylene (PTFE) hydrophobic hollow fiber membrane, the operating relative pressure is 0.25MPa, the temperature is 45°C, and the flow rate of dilute sulfuric acid with pH=5 is 3600m 3 / h; the liquid filter is CNII3300 filter, with a single processing capacity of 30m 3 / h, a total of 2 units; the design evaporation capacity of the evaporation and crystallization device is 42t / h, 2 sets are designed, each set is 21t / h, the design temperature difference of the steam compressor is 18°C, and the design temperature rise...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com