High-salt-content industrial wastewater electrodialysis-high pressure nanofiltration combined salt separation system

A high-pressure nanofiltration and industrial wastewater technology, applied in the field of water treatment, can solve the problems of reducing energy consumption and operating costs, accumulation of hazardous waste, secondary pollution, etc. stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

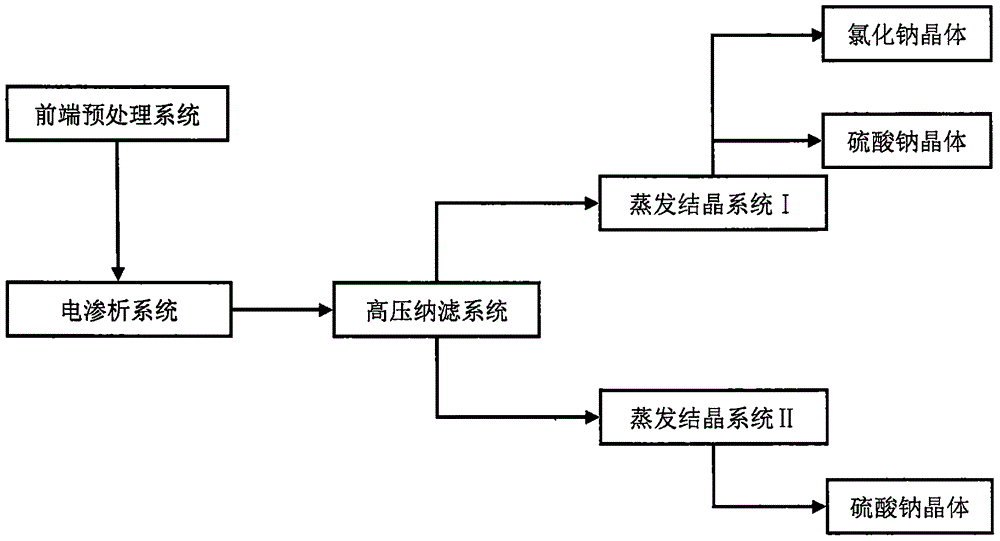

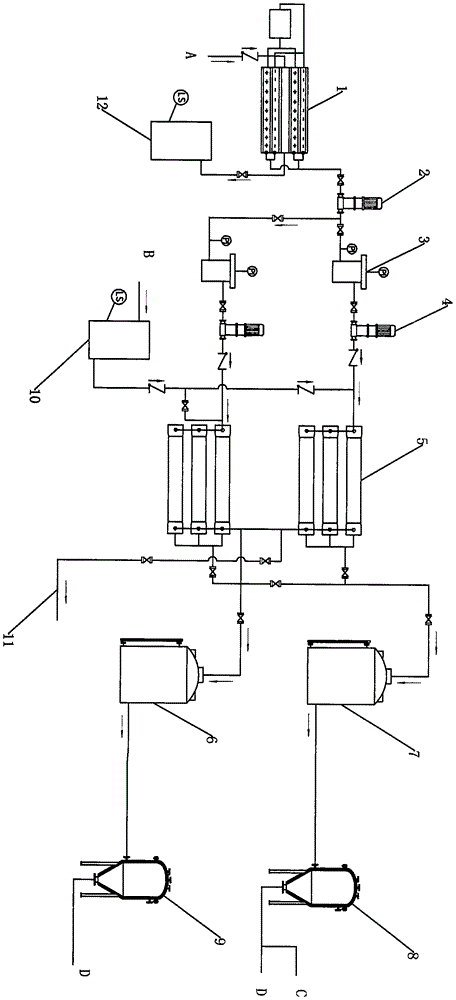

[0034] In order to verify the effect of the high-pressure nanofiltration system of the present invention on the high-salt concentrated water concentrated by the electrodialysis system, as figure 1 or figure 2 As shown, the high-salt industrial wastewater treatment project of a coal chemical enterprise is taken as an example to illustrate.

[0035] (1) The high-salt industrial wastewater fluctuates greatly, and the composition changes greatly. After the high-salt industrial wastewater to be treated is treated by the front-end pretreatment system and the electrodialysis system 1, the water quality of the high-salt concentrated water entering the high-pressure nanofiltration system The index is: TDS=79220mg / L, Cl - =18374mg / L, SO 4 2- =10819mg / L, the total hardness is 4.15mg / L. The pH is 7.5, and the flow rate is Q=20L / min.

[0036] (2) The high-salt concentrated water after softening and electrodialysis concentration through the front-end pretreatment, the high-salt concen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com