Method and device for jointly removing mercury from high-acidity chemical mercury-containing waste acid liquid

A technology for waste liquid and mercury removal, applied in the field of mercury treatment, can solve the problems of incomplete mercury removal, inability to meet stable standards, and inability to achieve, and achieve the effects of being beneficial to comprehensive utilization, reducing mercury content, and occupying less land.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

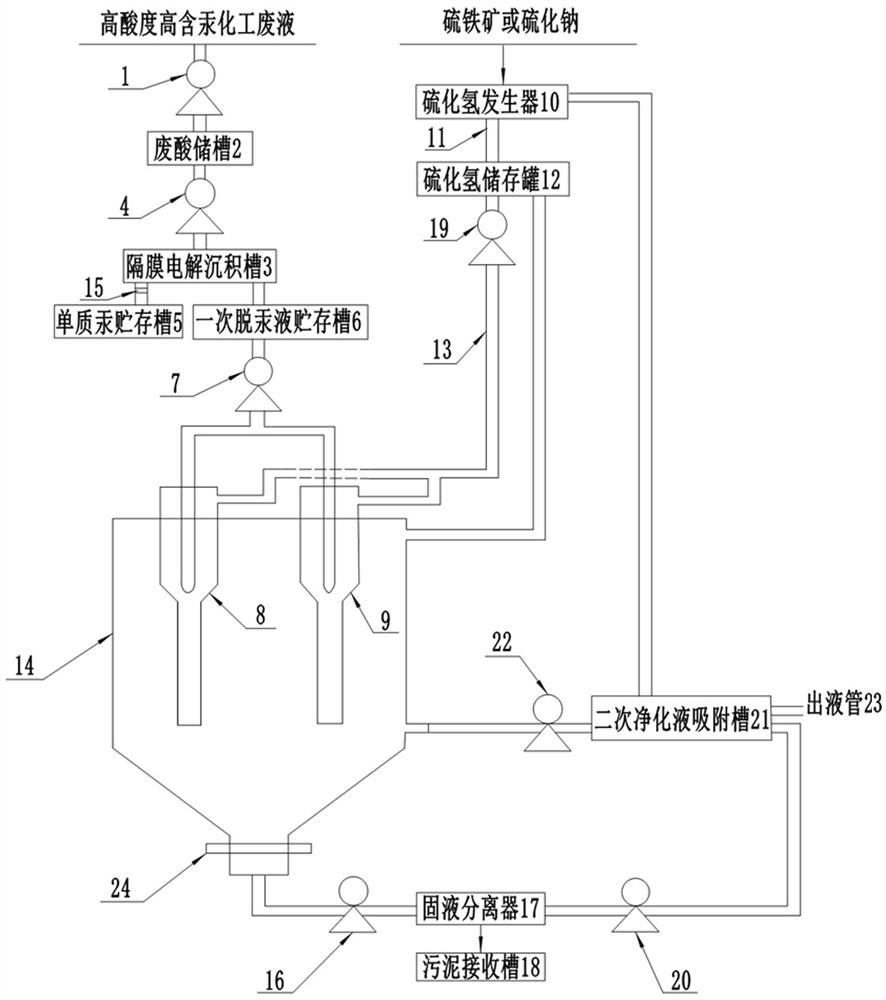

[0036] The high-acidity chemical mercury-containing waste liquid combined mercury removal device in this embodiment includes acid-resistant pumps (1, 4, 7, 20, 22), waste liquid storage tank 2, electrolytic deposition tank 3, elemental mercury storage tank 5, primary Mercury removal liquid storage tank 6, jet tube 8, jet tube 9, hydrogen sulfide generator 10, hydrogen sulfide storage tank 12, continuous vulcanization reaction device 14, mercury release stop valve 15, mud pump 16, solid-liquid separator 17, sewage Mud receiving tank 18, secondary purification liquid adsorption tank 21, liquid outlet pipe 23 and mud discharge stop valve 24.

[0037] The high-acidity chemical industry mercury-containing waste liquid combined mercury removal device in this embodiment consists of three parts:

[0038] (1) Diaphragm electrodeposition unit. Including waste liquid storage tank 2, electrolytic deposition tank 3, elemental mercury storage tank 5 and primary mercury removal liquid stora...

Embodiment 2

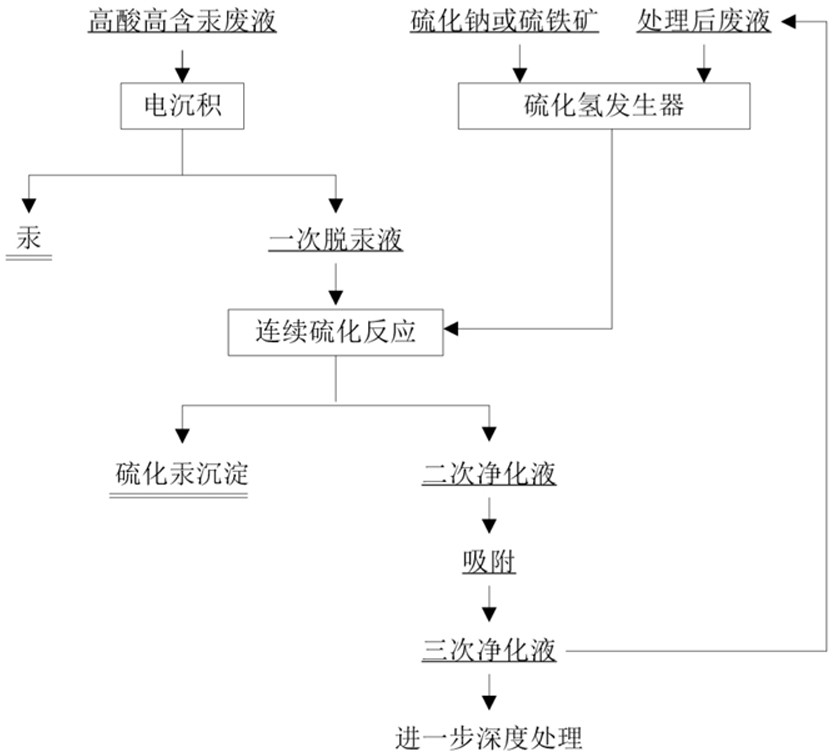

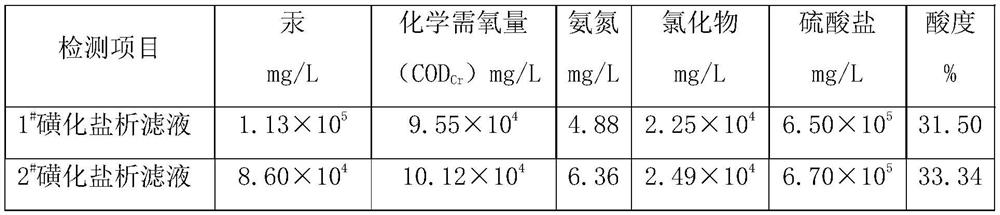

[0047] Take 1# chemical industry sulfonated salting-out filtrate for experimental research, the research process is as follows:

[0048] The first step is the step of removing mercury by diaphragm electrodeposition. The mercury concentration in the initial high-acidity chemical mercury-containing waste liquid is 11300mg / L, and the acid concentration is 31.50%. A vertical diaphragm electrolyzer is used. The diaphragm is a cation exchange membrane. Deposition cathode current density is 60A / m 2 , the same pole distance is 100mm, the additive thiourea is 0.5g / L, and the electrodeposition time is 60min. Cr 9.55×10 4 mg / L decreased to 3.6×10 4 mg / L or less, as shown in Table 2.

[0049] The second step is the step of continuous sulfidation and mercury removal. Seal the two jet tubes at the inlets on both sides of the three-necked flask. The hydrogen sulfide reactor is a conical flask with a sealed tee, and then seal it with a glass tube with a gas outlet. The gas guide tube is ...

Embodiment 3

[0052] Take 1# chemical industry sulfonated salting-out filtrate for experimental research, the research process is as follows:

[0053] The first step is the step of removing mercury by diaphragm electrodeposition. The mercury concentration in the initial high-acidity chemical mercury-containing waste liquid is 11300mg / L, and the acid concentration is 31.50%. A vertical diaphragm electrolyzer is used. The diaphragm is a cation exchange membrane. The anode uses a 10mm graphite plate and the cathode uses a 1mm stainless steel plate. The cathode current density of diaphragm electrodeposition is 70A / m 2 , the same pole distance is 100mm, the additive thiourea is 0.6g / L, and the electrodeposition time is 70min. Cr 9.55×10 4 mg / L decreased to 3.6×10 4 mg / L or less, as shown in Table 2.

[0054] The second step is the step of continuous sulfidation and mercury removal. Seal the two jet tubes at the inlets on both sides of the three-necked flask. The hydrogen sulfide reactor is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com