Preparation method and application of a mesoporous ferrous disulfide/silica microsphere composite solid-phase iron source

A microsphere and mesoporous technology is applied in the field of treatment of refractory organic pollutants, which can solve the problems of rapid loss of mineral iron sources, less surface active adsorption sites, incomplete degradation of pollutants, etc., so as to avoid secondary environmental pollution problems, Enhanced removal effect, wide-ranging effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Example 1: Mesoporous FeS 2 / SiO2 Microsphere composite catalyst (mesoporous FeS 2 / SiO 2 Preparation of Microsphere Composite Solid Phase Iron Source)

[0029] First crush, grind, sieve and wash the massive pyrite to obtain the pretreated FeS 2 particles. Then 0.2g of dodecylamine was dissolved in ethanol, and 0.5g of pretreated FeS was added under the condition of stirring. 2 The particles formed a mixture and kept stirring for 10 min. Then, add 1.2 g of tetraethyl orthosilicate to the above mixture and keep stirring for 180 minutes to form a solid gel, use centrifugation to separate the solid gel, wash the impurities on the surface of the solid gel with ethanol, and place the solid gel in a vacuum desiccator Keep at 60°C for 240min, and finally place it in a muffle furnace for calcination and keep at 600°C for 240min to remove the template to obtain mesoporous FeS 2 / SiO 2 Microsphere composite solid phase iron source.

[0030] Mesoporous SiO 2 Preparation m...

Embodiment 2

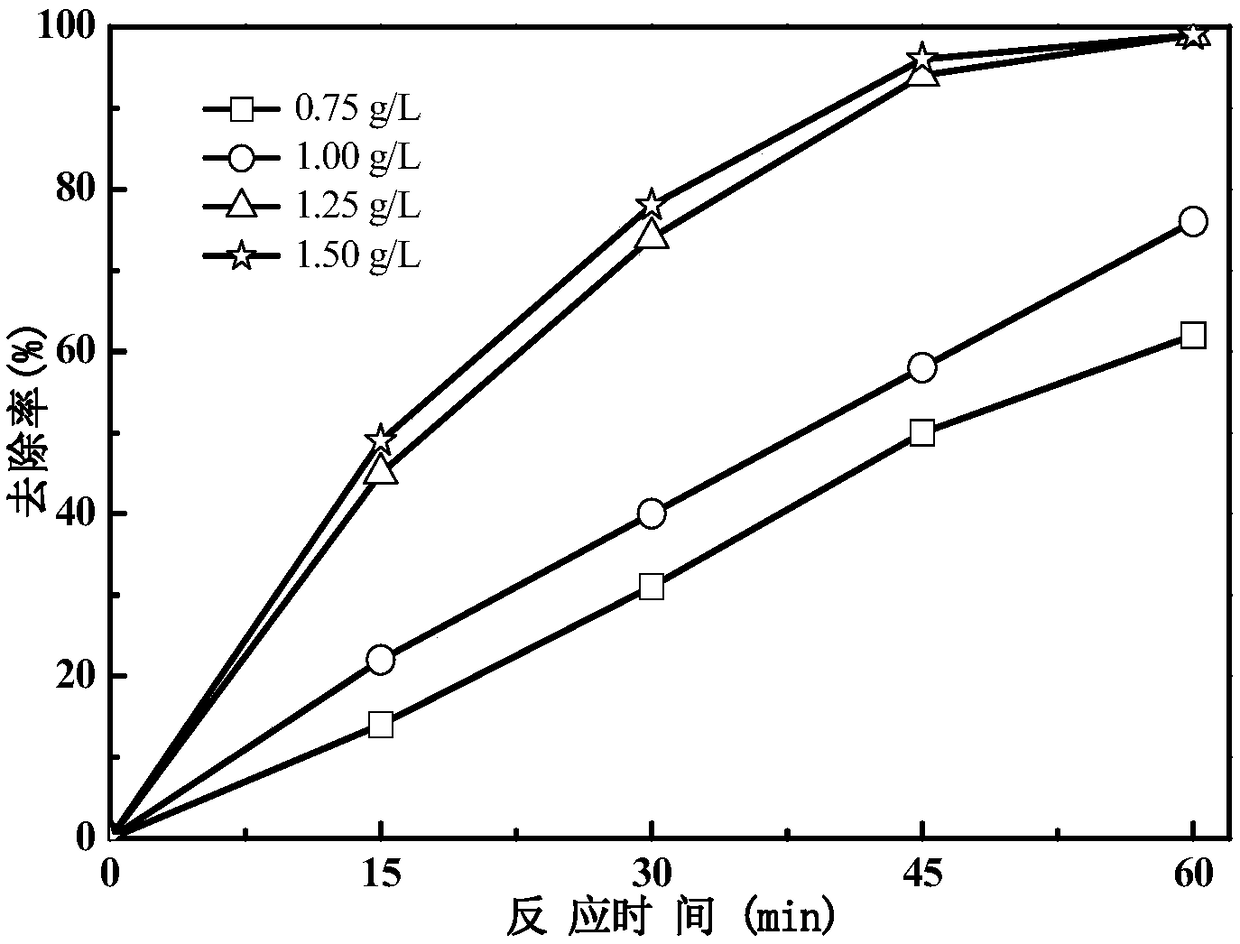

[0032] Add the mesoporous FeS prepared in Example 1 to the water containing ciprofloxacin 2 / SiO 2 Microsphere composite solid-phase iron source, with H 2 o 2 A new Fenton oxidation system was jointly constructed for the removal of ciprofloxacin in water. The specific steps of the method for removing ciprofloxacin are as follows: a 100mL Erlenmeyer flask is used as a reactor, and 50mL of water with a concentration of ciprofloxacin of 0.10mM is used as the treatment object, and the pH of the water is adjusted to 3.0. Adding mesoporous FeS to the reactor 2 / SiO 2 The microspheres were compounded with a solid-phase iron source so that the final concentration was 1.25g / L, and then added H 2 o 2 , so that the final concentration was 3 mM, and the reactor was placed on a magnetic stirrer to maintain uniform stirring, and the reaction time was 60 min.

Embodiment 3

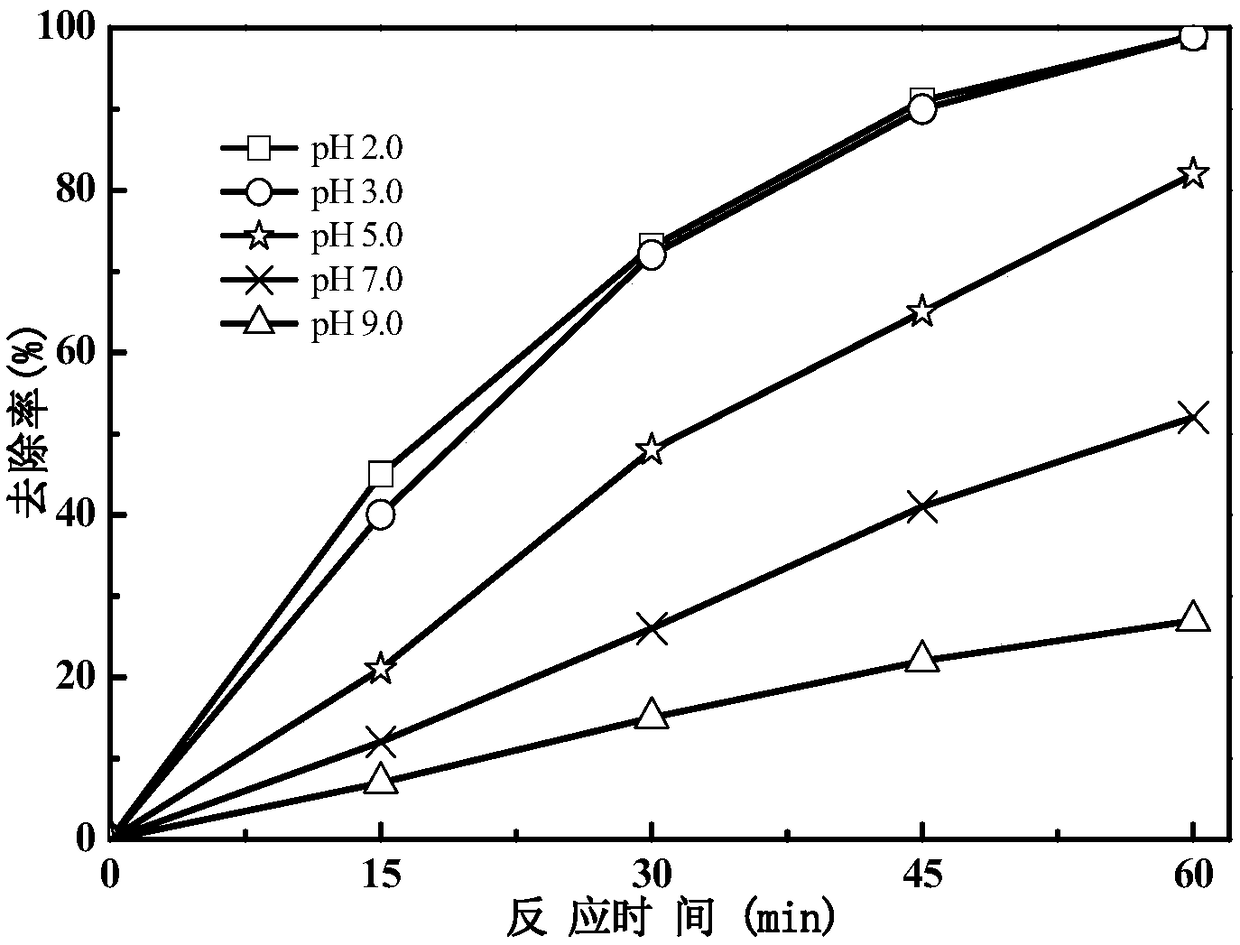

[0047] This embodiment is basically the same as Example 2, except that the pH of the water in the reactor is adjusted to 2, 3, 5, 7 and 9 respectively, and all the other conditions are the same as those in Example 2 to measure the removal of ciprofloxacin in the water. Effect. The result is as figure 1 shown. Depend on figure 1 It can be seen that under this new Fenton oxidation system, the removal rate of ciprofloxacin decreases with the increase of pH. During the reaction period of 60 minutes, the removal rate of ciprofloxacin reached the maximum (nearly 100%) in the range of pH 2-3. Subsequently, the removal rate of ciprofloxacin showed a trend of rapid decline with the increase of pH.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com