Complete equipment for corn straw efficient impurity removal and impurity removal method thereof

A corn stalk and complete set of equipment technology, applied in chemical instruments and methods, solid separation, sieving and other directions, can solve the problems of comprehensive utilization of straw, increase processing procedures and costs, etc., to promote the construction of ecological civilization, promote resource conservation, The effect of improving agricultural efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

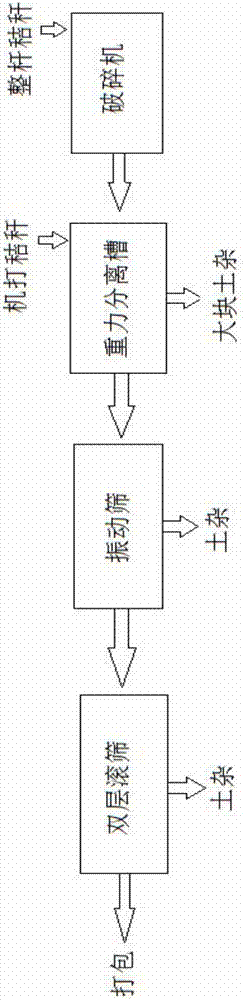

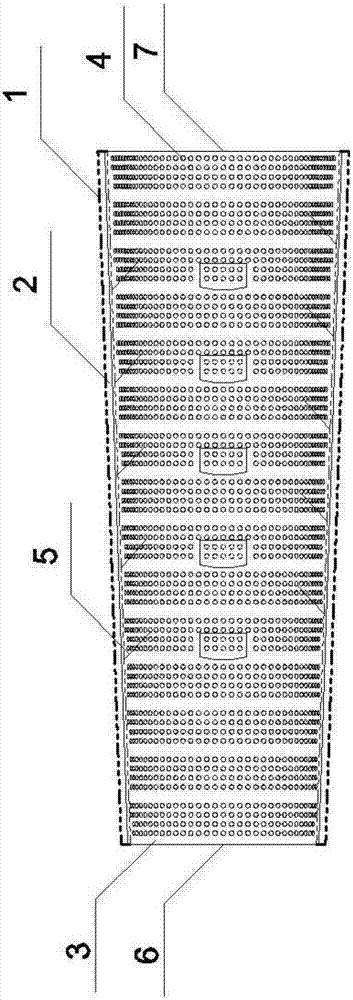

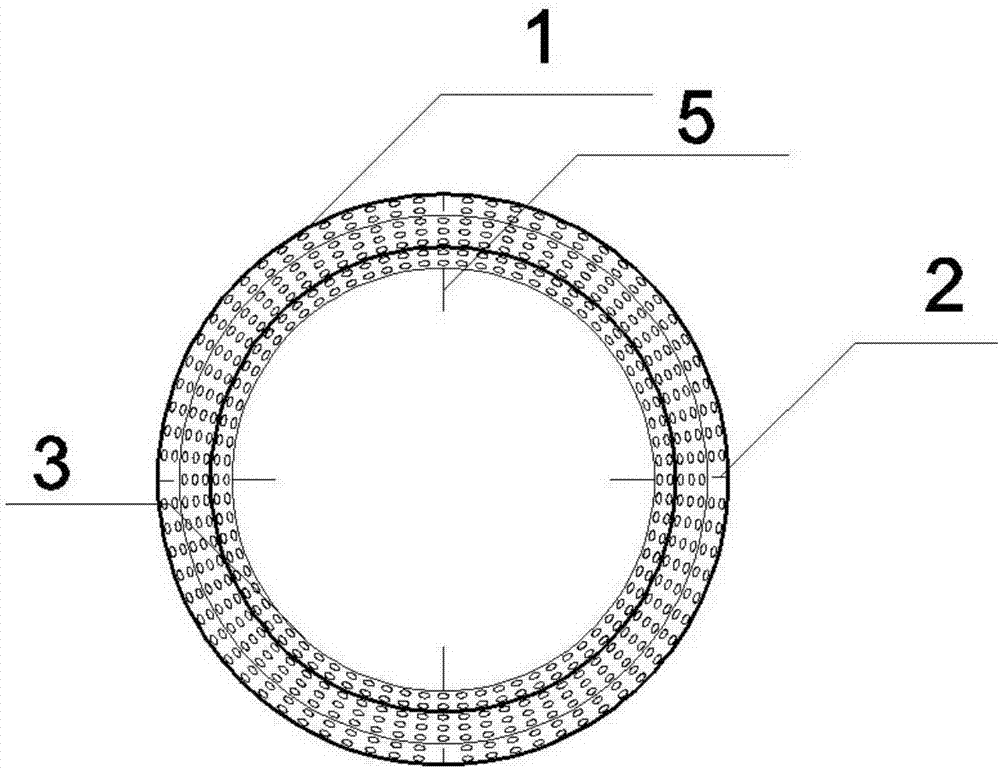

[0063] The technology of the invention provides a complete set of equipment for high-efficiency impurity removal of corn stalks, including a gravity separation tank, a vibrating separation screen and a double-layer rolling separation screen. According to the principle of physical separation, firstly, the principle of gravity separation is used to separate the large pieces of soil and impurities contained in the straw in the gravity separation tank. Then, the soil and impurities adhered to the surface are further separated through the double-layer rolling separation screen. In the double-layer rolling separation screen, three rows of 15-30-degree wedge-shaped baffles (120-degree interval between each row) are set around the center line of the feed inlet. , evenly arranged along the axial direction, the inner drum screen is provided with evenly arranged sieve holes with a diameter of 30-50mm, the soil and impurities adhering to the surface of the straw are discharged from the sie...

Embodiment 2

[0065] The technology of the invention provides a complete set of equipment for high-efficiency impurity removal of corn stalks, including a gravity separation tank, a vibrating separation screen and a double-layer rolling separation screen. According to the principle of physical separation, firstly, the principle of gravity separation is used to separate the large pieces of soil and impurities contained in the straw in the gravity separation tank. Then, the soil and impurities adhered to the surface are further separated through the double-layer rolling separation screen. In the double-layer rolling separation screen, four rows of 15-30-degree wedge-shaped deflectors are arranged around the center line of the feed inlet (the interval between each row is 90 degrees). , evenly arranged along the axial direction, the inner drum screen is provided with evenly arranged sieve holes with a diameter of 30-50mm, the soil and impurities adhering to the surface of the straw are discharge...

Embodiment 3

[0067] The technology of the invention provides a complete set of equipment for high-efficiency impurity removal of corn stalks, including a gravity separation tank, a vibrating separation screen and a double-layer rolling separation screen. According to the principle of physical separation, firstly, the principle of gravity separation is used to separate the large pieces of soil and impurities contained in the straw in the gravity separation tank. Then, the soil and impurities adhered to the surface are further separated through the double-layer rolling separation screen. In the double-layer rolling separation screen, three rows of 15-30-degree fish-scale deflectors are arranged around the center line of the feeding port (the interval between each row is 120 degrees). ), evenly arranged along the axial direction, the inner drum screen is provided with evenly arranged sieve holes with a diameter of 30-50mm, the soil and impurities adhering to the surface of the straw are discha...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Mesh diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com