A kind of hydrocyclone with cone slit structure

A technology of hydrocyclones and cones, which is applied in the direction of swirling devices and devices in which the axial direction of the swirling flow can be reversed, etc., which can solve the problems of increased pressure drop, large pressure drop, and high energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

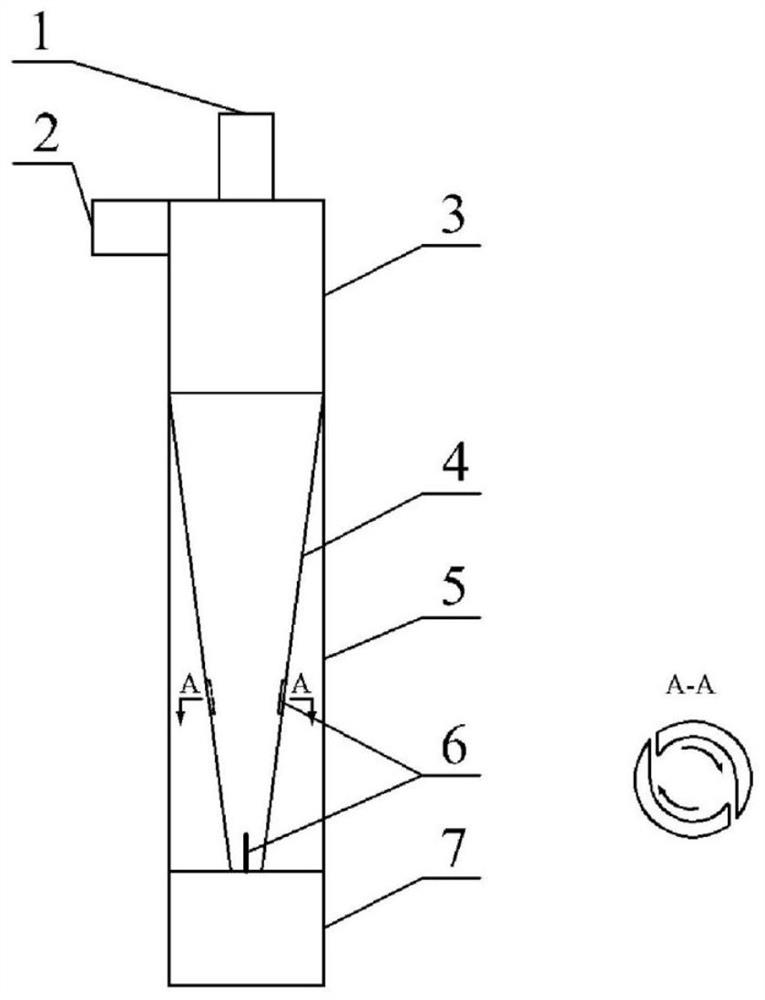

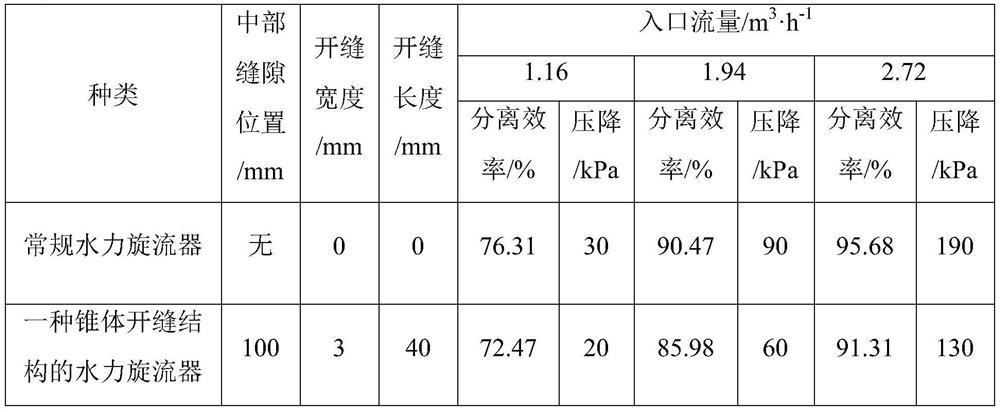

[0016] In this embodiment, the feed pipe 2 of the hydrocyclone and the cylindrical section 3 are self-contained, the overflow pipe 1 and the cylindrical section 3, the cylindrical section 3 and the conical section 4 and the casing 5, the casing 5 and the underflow pipe 7 are all Connection by flange. The cylindrical section 3 is 70mm high and 50mm in diameter, and the conical section 4 is 380mm high. Two symmetrical slits with an interval of 180° are opened at the bottom and the middle of the cone section 4 respectively, with a length of 40mm and a width of 3mm.

[0017] The liquid-solid mixture to be separated is transported to the feed pipe 2 through the slurry pump, and then enters the cylindrical section 3 of the hydrocyclone horizontally and tangentially to form a swirling flow. Due to the density difference of the liquid-solid mixture, under the action of centrifugal force, the solid particles are thrown to the side wall as a heavy phase, and make a spiral motion downwa...

Embodiment 2

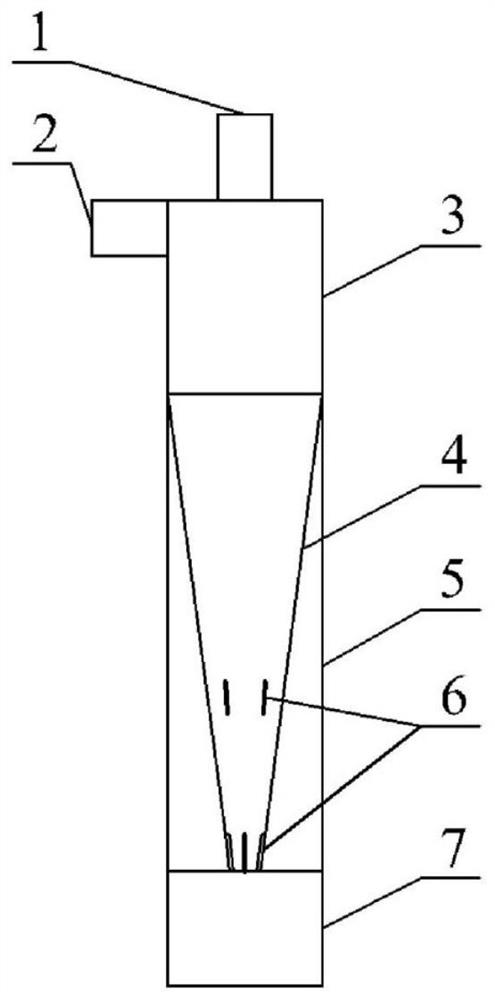

[0023] In this embodiment, the feed pipe 2 of the hydrocyclone and the cylindrical section 3 are self-contained, the overflow pipe 1 and the cylindrical section 3, the cylindrical section 3 and the conical section 4 and the casing 5, the casing 5 and the underflow pipe 7 are all Connection by flange. The cylindrical section 3 is 70mm high and 50mm in diameter, and the conical section 4 is 380mm high. Four symmetrical slits with an interval of 90° are opened at the bottom and the middle of the cone section 4 respectively, the length is 20mm, the width is 1mm, and the lower end of the middle slit is 120mm from the bottom of the cone section 4.

[0024] The liquid-solid mixture to be separated is transported to the feed pipe 2 through the slurry pump, and then enters the cylindrical section 3 of the hydrocyclone horizontally and tangentially to form a swirling flow. Due to the density difference of the liquid-solid mixture, under the action of centrifugal force, the solid partic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com