Device and method for separation of thin bottle sheet and label paper

A separation device and label paper technology, which is applied in the field of chemical fiber separation label paper devices, can solve problems such as difficulty in separation, and achieve the effects of reducing the labor of workers, improving the stability of discharging materials, and having a simple structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The specific implementation manner of the present invention will be described in detail below in conjunction with the accompanying drawings.

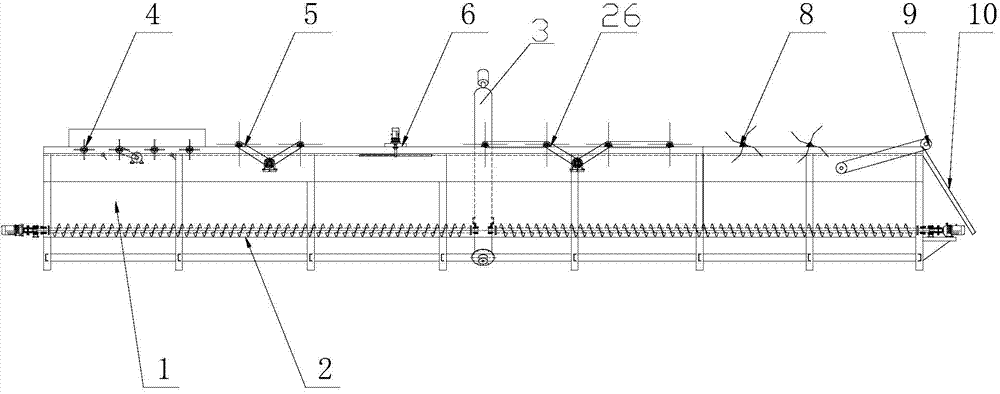

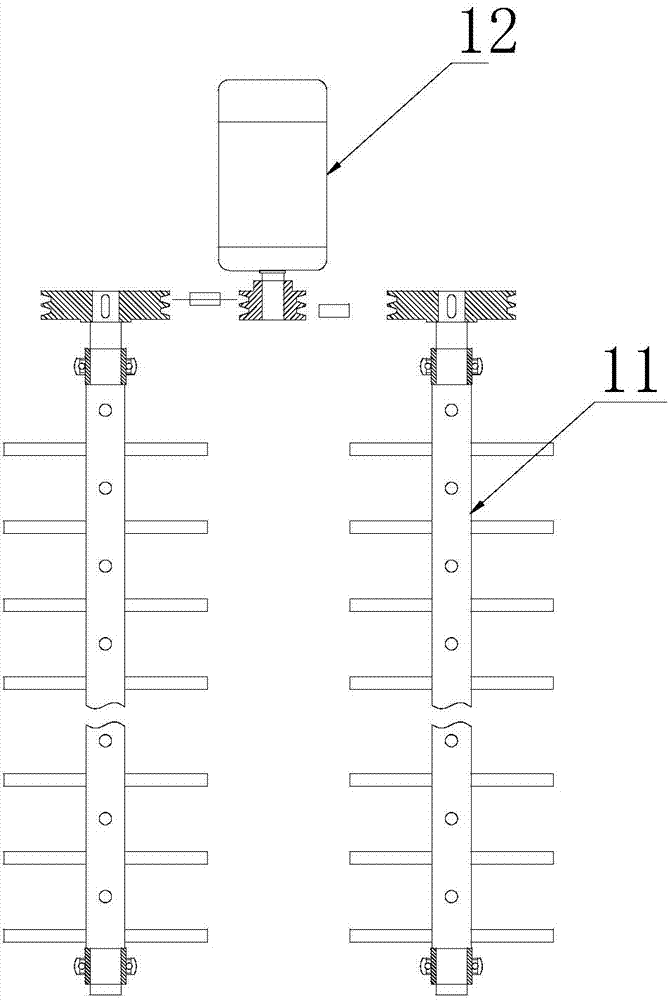

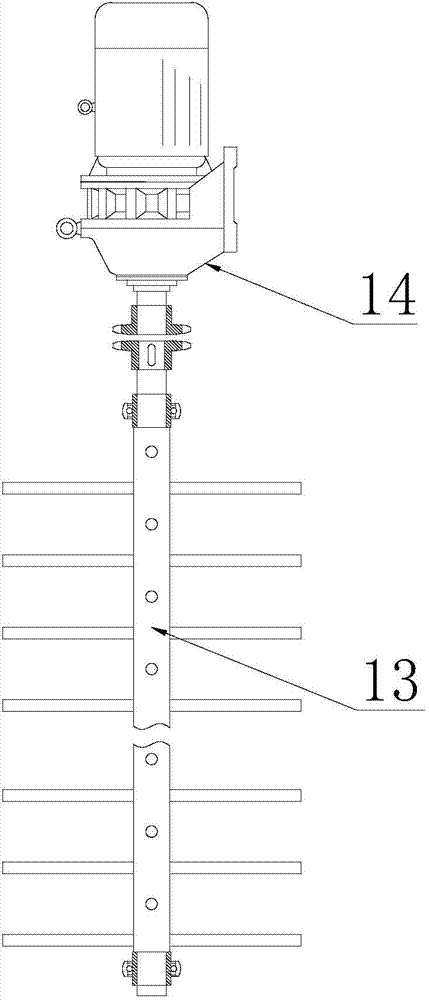

[0029] Such as figure 1 A separation device for thin bottle flakes and label paper is shown, the separation device is a separation tank, and an auger semi-cylinder is provided at the bottom of the separation tank 1, and two mutual Connected flat push auger 2; the upper part of the separation tank 1 is respectively provided with four groups of rod-making bulk material mechanism 4, the first slow-speed rod-drawing push mechanism 5, the pressing rotation mechanism 6, the second slow-speed rod-stroke push mechanism 26, Two sets of scraper pushing mechanism 8 and net-type discharge inclined conveyor belt device 9 are provided with an inclined discharge water filter mechanism 10 at the outlet of the separation tank 1, and after the separation tank 1 is behind the pressing rotating mechanism 6 End is provided with a notch, is provided ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com