Method for treating non-ferrous metal smelting off-gas through copper smelting fume

A technology for non-ferrous metals and smelting flue gas, which is applied in gas treatment, separation methods, chemical instruments and methods, etc., can solve problems affecting economy, high energy consumption, and large consumption, and achieve improved economy, high energy consumption, The effect of less investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

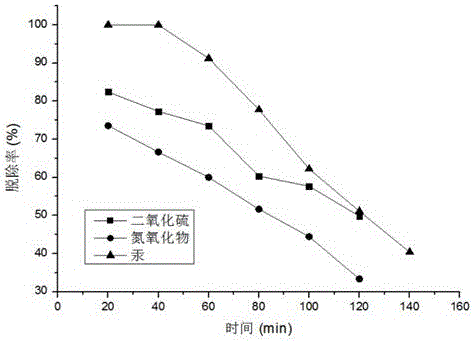

[0023] Collect and grind the dust in the flue gas of copper smelting and sieve it into 200-400 meshes, then mix it with water in a fixed bed reactor at a mass volume ratio of 5:1 to form an absorption liquid at a temperature of 30°C, prepared by a simulated flue gas system Simulated flue gas, of which 1000ppmSO 2 , 300ppmNO, 30mg / m 3 Hg, 3%O 2 , the simulated flue gas is introduced into the fixed bed reactor to react with the absorption liquid, and the NO and NO in the outlet gas 2 and SO 2 The concentration is detected by a multi-component infrared flue gas analyzer, and the Hg concentration in the inlet and outlet gases is detected by a cold atomic absorption mercury analyzer. Such as figure 1 As shown, in the simultaneous desulfurization, denitrification and demercuration laboratory of copper smelting dust, within 60 minutes, the mercury removal efficiency can be maintained above 90%, the desulfurization efficiency can be maintained above 70%, and the denitrification ef...

Embodiment 2

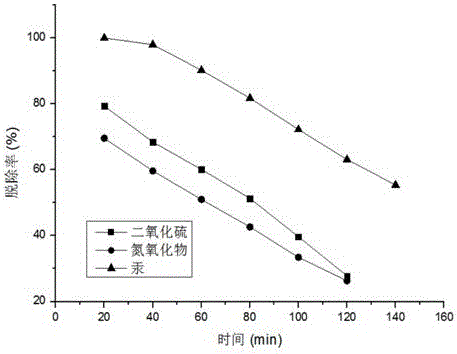

[0025] Collect and grind the dust in the flue gas of copper smelting and sieve it into 200-400 meshes, then mix it with water in a fixed bed reactor at a mass volume ratio of 7:1 to form an absorption liquid at a temperature of 40°C, prepared by a simulated flue gas system Simulated flue gas, of which 1300ppmSO 2 , 400ppmNO, 40mg / m 3 Hg, 5% O 2 , the simulated flue gas is introduced into the fixed bed reactor to react with the absorption liquid, and the NO and NO in the outlet gas 2 and SO 2 The concentration is detected by a multi-component infrared flue gas analyzer, and the Hg concentration in the inlet and outlet gases is detected by a cold atomic absorption mercury analyzer. Such as figure 2 As shown, in the simultaneous desulfurization, denitrification and demercuration laboratory of copper smelting dust, within 60 minutes, the mercury removal efficiency can be maintained above 90%, the desulfurization efficiency can be maintained above 60%, and the denitrification ...

Embodiment 3

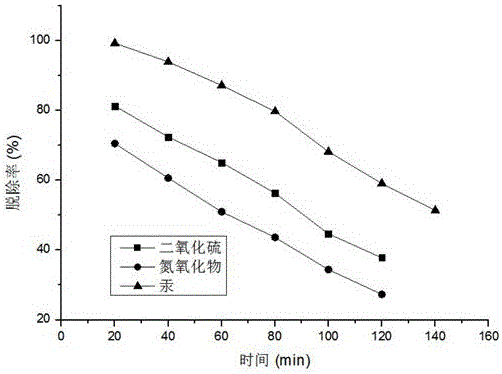

[0027] Collect and grind the dust in the flue gas of copper smelting and sieve it into 200-400 meshes, then mix it with water in a fixed bed reactor at a mass volume ratio of 9:1 to form an absorption liquid at a temperature of 50°C, prepared by a simulated flue gas system Simulated flue gas, of which 1500ppmSO 2 , 500ppmNO, 50mg / m 3 Hg, 7%O 2 , The simulated flue gas is introduced into the fixed bed reactor to react with the absorption liquid, and the NO and NO in the outlet gas 2 and SO 2 The concentration is detected by a multi-component infrared flue gas analyzer, and the Hg concentration in the inlet and outlet gases is detected by a cold atomic absorption mercury analyzer. Such as image 3As shown, in the simultaneous desulfurization, denitrification and mercury removal laboratory of copper smelting dust, within 60 minutes, the mercury removal efficiency can be maintained above 87%, the desulfurization efficiency can be maintained above 65%, and the denitrification e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com