Mercury curing and removing method for coal-fired power plant and device thereof

A coal-fired power plant, removal technology, applied in the direction of chemical instruments and methods, separation methods, dispersed particle separation, etc., can solve problems such as environmental pollution, high investment costs, activated carbon regeneration, etc., to avoid secondary pollution and improve desulfurization efficiency , the effect of reducing mercury content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

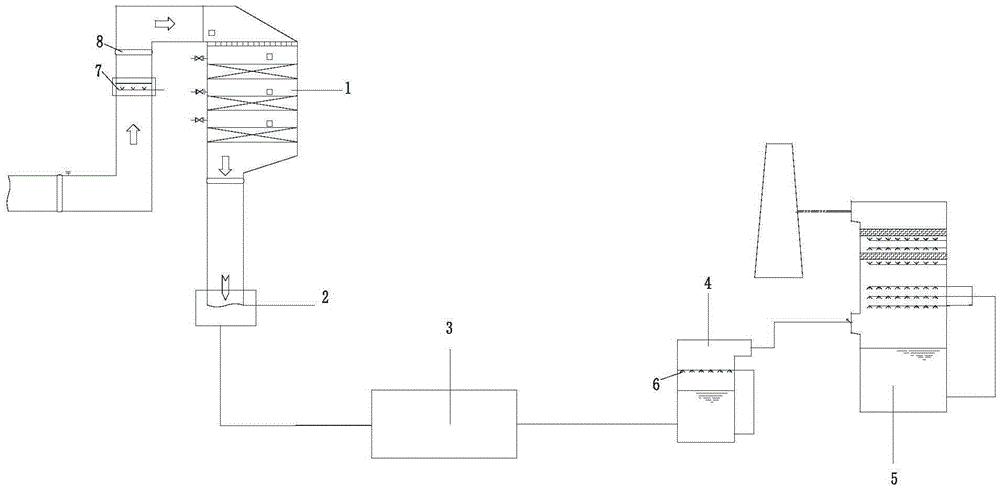

[0035] The flue gas from the boiler passes through the SCR reactor 1 to remove nitrogen oxides, then passes through the air preheater 2, and then enters the dry electrostatic precipitator 3 to remove dust. The mercury collection reactor 4 of the sulfide solution with a pH value of 9 removes divalent mercury in the flue gas; the flue gas treated with mercury removal enters the desulfurization absorption tower 5 to remove sulfur dioxide and then emits it.

Embodiment 2

[0037] The flue gas from the boiler passes through the SCR reactor 1 to remove nitrogen oxides, then passes through the air preheater 2, and then enters the dry electrostatic precipitator 3 to remove dust. Divalent mercury in the flue gas is removed in the mercury collection reactor 4 of the sulfide solution with a pH value of 11; the flue gas treated with mercury removal enters the desulfurization absorption tower 5 to remove sulfur dioxide and then is discharged.

Embodiment 3

[0039] The flue gas from the boiler passes through the SCR reactor 1 to remove nitrogen oxides, then passes through the air preheater 2, and then enters the dry electrostatic precipitator 3 to remove dust. The flue gas after electrostatic dust removal enters the container at a flow rate of 3.5m / s Divalent mercury in the flue gas is removed in the mercury collection reactor 4 with a sulfide solution with a pH value of 10; the flue gas treated with mercury removal enters the desulfurization absorption tower 5 to remove sulfur dioxide and then is discharged.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com