Oxidizing method for removing gaseous elemental mercury in boiler fume

A technology for boiler flue gas and elemental mercury is applied in the field of flue gas purification, which can solve the problems of unknown environmental impact, low system efficiency, and large impact on the quality of activated carbon, so as to reduce production and operation costs, simple production process, and discharge effect. Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

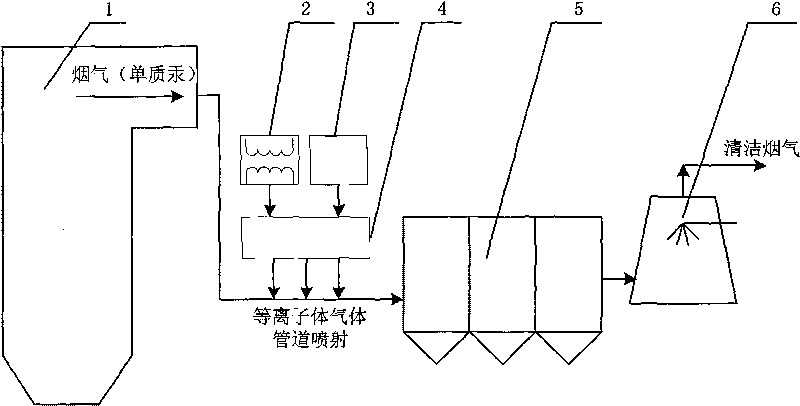

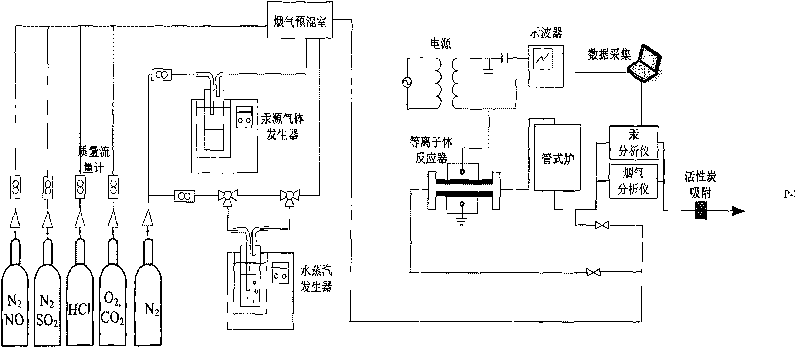

[0053] In Example 1, the effects of dielectric barrier discharge plasma catalytic oxidation and removal of elemental mercury were tested under various simulated flue gas atmospheres. Including tests for the following conditions:

[0054] 1) simulated flue gas CO 2 / H 2 O / O 2 / N 2 / Hg atmosphere, the total simulated flue gas flow rate is 3.5L.min -1 , nitrogen is the balance gas, the concentration of carbon dioxide is 8.5%, the concentration of water vapor is 5%, the concentration of oxygen is 4.5%, and the concentration of mercury is kept at 22.3μg.Nm -3 Around, the discharge voltage is 6kV.

[0055] When the dielectric barrier discharge plasma reactor is energized and the space gas is broken down and discharged, the concentration of elemental mercury drops rapidly to 2.2-2.4 μg.Nm -3 about. When the power is turned off, the concentration of elemental mercury in the flue gas quickly returns to the initial concentration level. The oxidation removal rate of elemental mer...

Embodiment 2

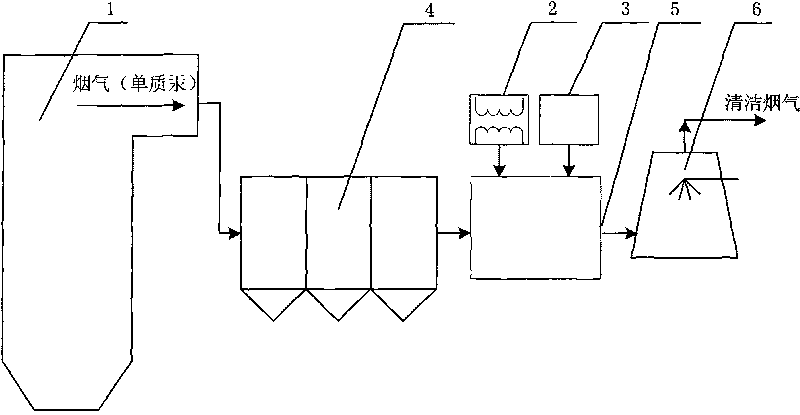

[0058] In Example 2, in a real flue gas atmosphere, the effect of using dielectric barrier discharge plasma to catalyze oxidation and remove elemental mercury was tested. Including tests for the following conditions:

[0059] The total simulated flue gas flow rate is 10000m 3 .h -1 , the fuel is bituminous coal, the flue gas temperature is 160°C, and the tested mercury concentration is kept at 12.5μg.Nm -3 Around, other main gas components in the flue gas are: SO2: 1050ppm, CO2: 9.4%, O2: 4.7%, HCl: 122ppm, and the discharge voltage is 2-7kV. It can be seen that with the increase of voltage, the removal efficiency of elemental mercury can reach more than 85%, and the voltage rises to a certain level, which has little effect on the removal efficiency. Therefore, the energy consumption of flue gas mercury removal devices of different boilers can be proposed. optimized design.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com