Thermal desorption combined utilization and waste heat recycling method and system adopted by method

A technology of waste heat recovery and thermal desorption, which is applied in the field of soil remediation, can solve the problems of low safety hazards in dust production, high safety hazards, and small processing capacity, and achieve high safety and environmental protection efficiency, fuel cost saving, and large processing capacity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

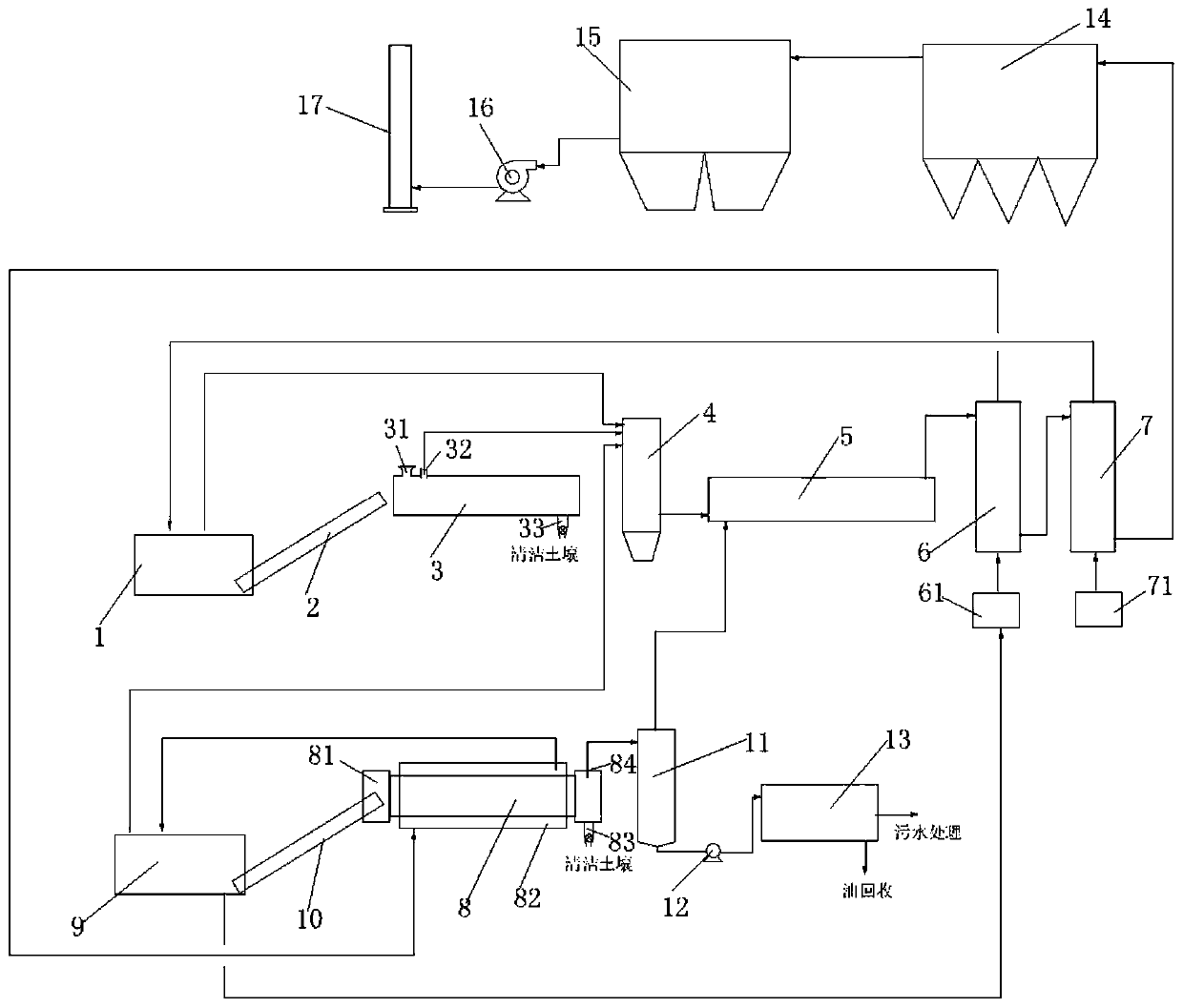

[0023] The technical scheme of the present invention will be further described below in conjunction with the accompanying drawings.

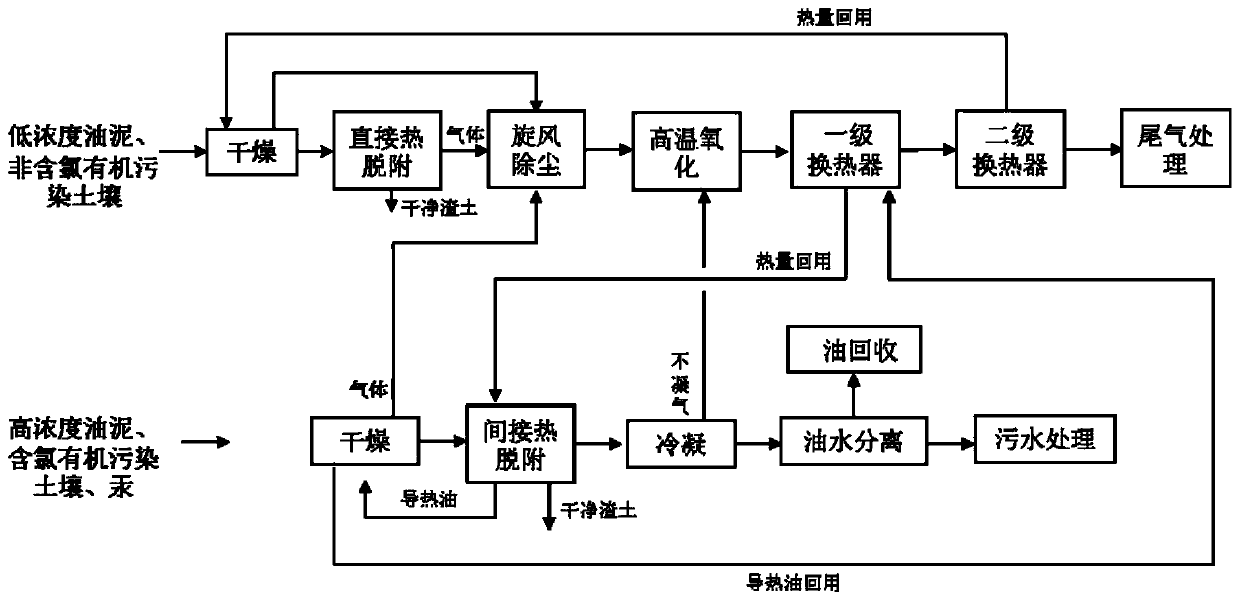

[0024] Such as figure 1 As shown, the combined use of thermal desorption and waste heat recovery and utilization method of the present invention includes the following processing steps:

[0025] (1) Dry and direct thermal desorption treatment of low-concentration oil sludge and non-chlorinated organic-contaminated soil, so that the soil temperature rises above the boiling point of the target pollutant. After treatment, the clean residue is discharged, and the generated waste gas is passed through the cyclone Dust removal;

[0026] (2) Dry high-concentration oil sludge, chlorine-containing organic contaminated soil, and mercury-contaminated soil through drying and indirect thermal desorption to raise the temperature of the contaminated soil to above the boiling point of the target pollutant. The exhaust gas is sequentially treated by condensati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com