Method and system for treating high-chlorine desulfurization waste water by electrolytic method and performing flue gas mercury pollution control

A desulfurization wastewater, electrolysis technology, applied in water pollutants, gas treatment, precipitation treatment, etc., can solve the problems of high vapor pressure, difficult to directly capture, insoluble in water, etc., to reduce emissions, reduce equipment costs, The effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The present invention provides a method and system for electrolytic treatment of high-chloride desulfurization wastewater and its use in flue gas mercury pollution control. The present invention will be further described below in conjunction with the accompanying drawings and examples, and the contents of the examples are not intended to limit the scope of protection of the present invention.

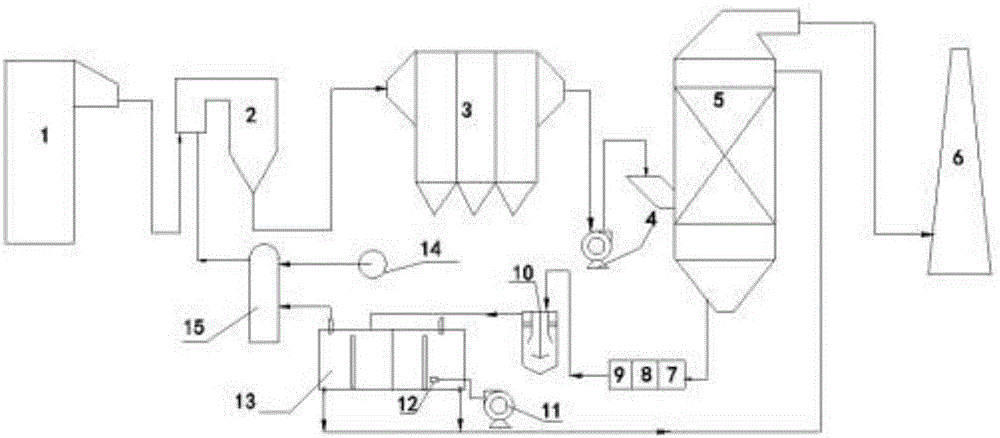

[0044] Such as figure 1 As shown, an electrolysis method is used to treat high-chloride desulfurization wastewater and is used for flue gas mercury pollution control. The system includes: coal-fired power plant boiler 1, SCR system 2, dust removal equipment 3, induced draft fan 4, wet scrubber 5, chimney 6, neutralization Box 7, mixing box 8, flocculation box 9, inclined plate clarifier 10, electrolysis device 13, bubbling reactor 12, air compressor 11, compressed air source 14, chlorine liquefier 15.

[0045] The flue gas produced by the coal-fired power plant boiler 1 enters the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com