Method for removing mercury from mercury pollution materials

A mercury pollution and removal technology, applied to the removal of solid waste, etc., to achieve the effect of reducing mercury content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

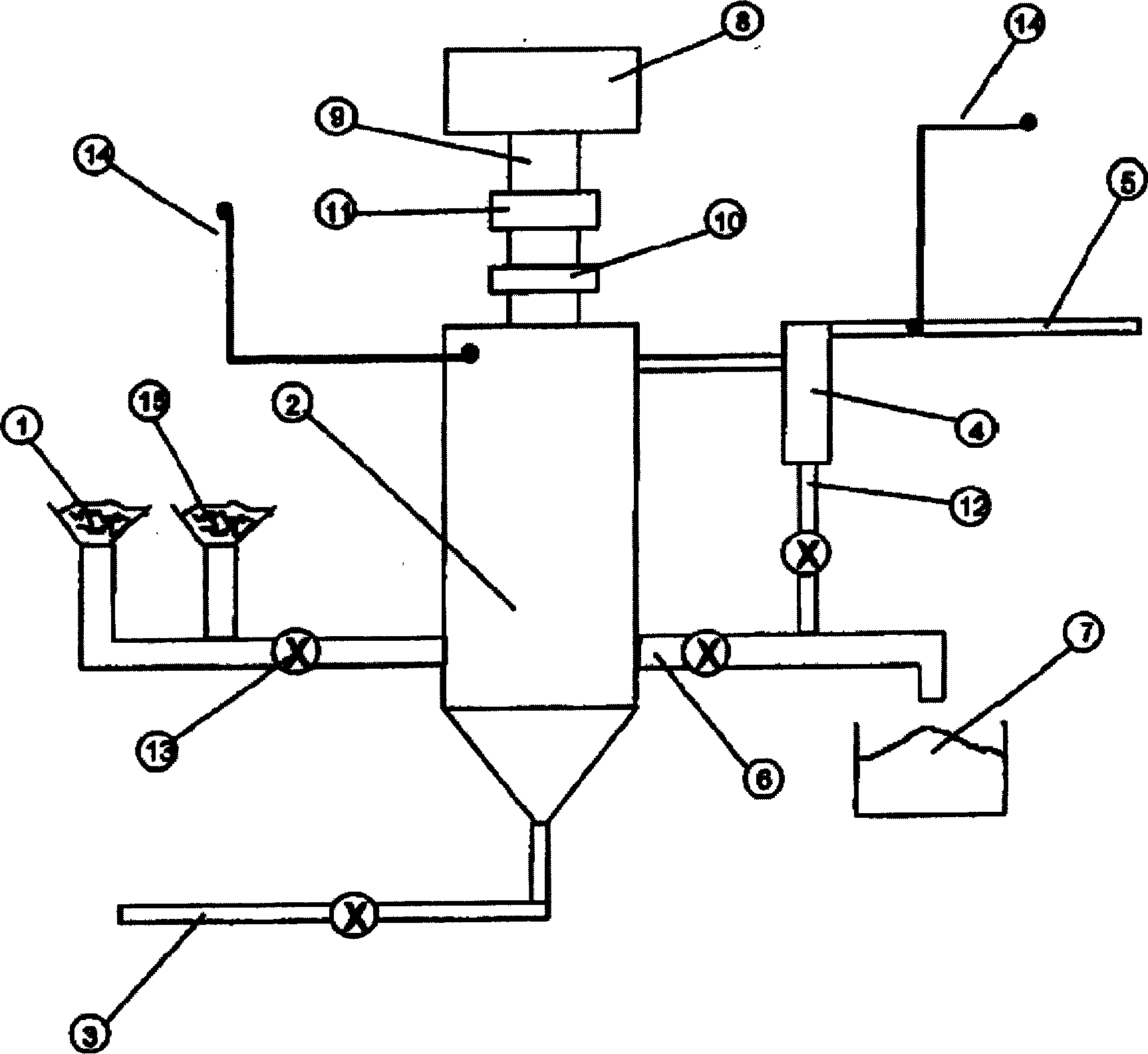

[0045] Assembled as figure 1 Schematic representation of equipment to process a quantity of coal combustion fly ash known to contain mercury. A microwave frequency of 915MHz is used. The fluidizing gas is ambient air.

[0046] The feed fly ash is processed at a temperature of about 820°C. The material passed through the reactor vessel at a rate of approximately 6 pounds per minute (lbs) throughout the approximately 400 minute duration of the test.

[0047] The mercury content in the feed was measured to be 79 parts per billion (ppb). The unburned carbon content, characterized by LOI (loss on ignition), was measured to be 8.5%.

[0048] Treated ash samples were periodically taken from the experiment and measured for mercury content. The results obtained are shown in Table 1 below. The LOI of the treated material was 1.5%.

[0049] time

[0050] As can be seen from the table, once the process has reached steady state operation with respect to mercury precipitat...

example 2

[0052] Assembled as figure 1 Schematic representation of equipment to process a quantity of coal combustion fly ash known to contain mercury. A microwave frequency of 915MHz is used. The fluidizing gas is ambient air.

[0053] The feed fly ash is processed at a temperature of about 820°C. The material passed through the reactor vessel at a rate of approximately 6 pounds per minute (lbs) throughout the approximately 500 minute duration of the test.

[0054] The mercury content in the feed was measured to be 33 parts per billion (ppb). The unburned carbon content, characterized by LOI (loss on ignition), was measured to be 17.5%.

[0055] Treated ash samples were periodically taken from the experiment and measured for mercury content. The results obtained are shown in Table 2 below. The LOI of the treated material was 0.4%.

[0056] time (min

example 3

[0058] Assembled as figure 1 Schematic representation of equipment to process a quantity of coal combustion fly ash known to contain mercury. A microwave frequency of 915MHz is used. The fluidizing gas is ambient air.

[0059] The feed fly ash is processed at a temperature of about 820°C. The material passed through the reactor vessel at a rate of approximately 6 pounds per minute (lbs) throughout the approximately 400 minute duration of the test.

[0060] The mercury content in the feed was measured to be 142 parts per billion (ppb). The unburned carbon content, characterized by LOI (loss on ignition), was measured to be 4.5%.

[0061] Treated ash samples were periodically taken from the experiment and measured for mercury content. The results obtained are shown in Table 3 below. The final LOI was 0.3%.

[0062] time

(minute)

product mercury

(ppb)

cyclone mercury

(ppb)

0

142

142

187

8

7

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com