Method for realizing hydrochloric acid closed cycle and precluding mercury pollution in polychloroethylene production

A technology of polyvinyl chloride and hydrochloric acid is applied in the field of realizing closed-circuit circulation of hydrochloric acid and eliminating mercury pollution in the production of polyvinyl chloride, and can solve the problems of deterioration of hydrogen chloride process conditions, inability to discharge hydrogen chloride, and rising operating temperature of a foam pickling tower system.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

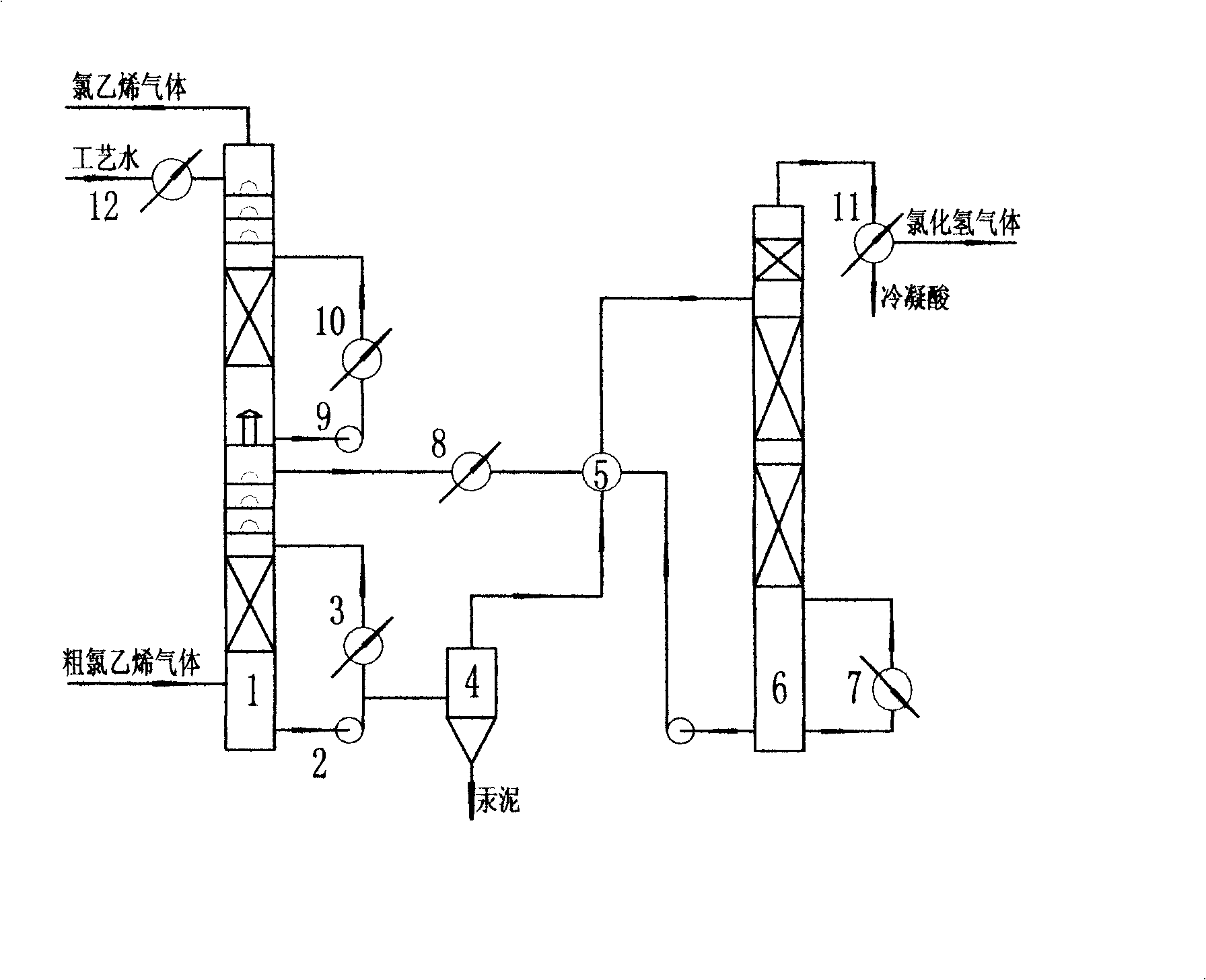

[0030] Brief description of the process: 1. Vinyl chloride process: the crude vinyl chloride from the vinyl chloride synthesis system enters the bottom of the lower section of the pickling tower after mercury removal by the mercury remover, and is sprayed from top to bottom in the packing layer and in the tower Circulating hydrochloric acid is in countercurrent contact to complete the mass transfer process. The hydrogen chloride in the gas phase is dissolved in the liquid phase. After passing through the packing layer, the gas continues to rise. In the plate column section, it is in countercurrent contact with the circulating hydrochloric acid with a lower concentration newly added to the tower to continue to absorb the hydrogen chloride in it. Then enter the upper section of the pickling tower. It enters the bottom of the upper part of the pickling tower, and contacts in the packing layer with the circulating dilute hydrochloric acid sprayed from top to bottom in the tower to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com