Mercury pollution soil thermal desorption and mercury recovery method and integrated equipment

A mercury pollution and thermal desorption technology, applied in the restoration of contaminated soil, etc., can solve the problems of waste of resources, no mercury collection, etc., and achieve the effect of simple process, pollution problem solving and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

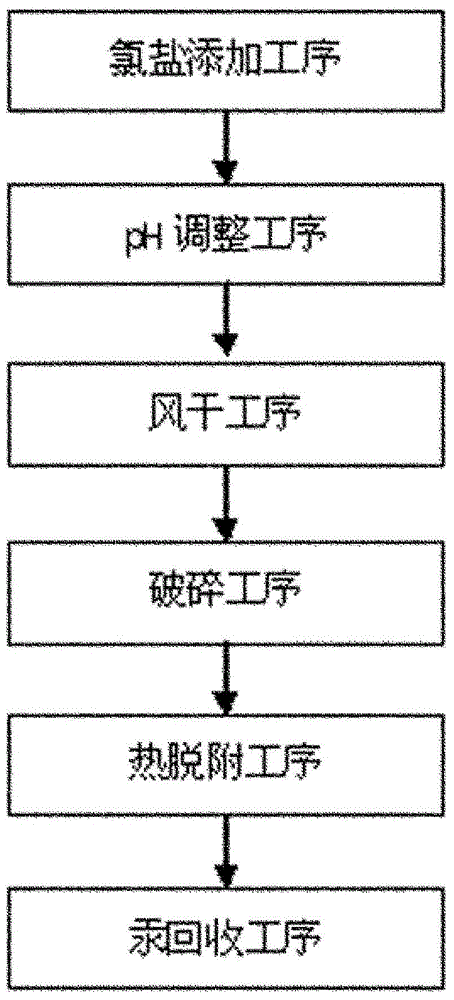

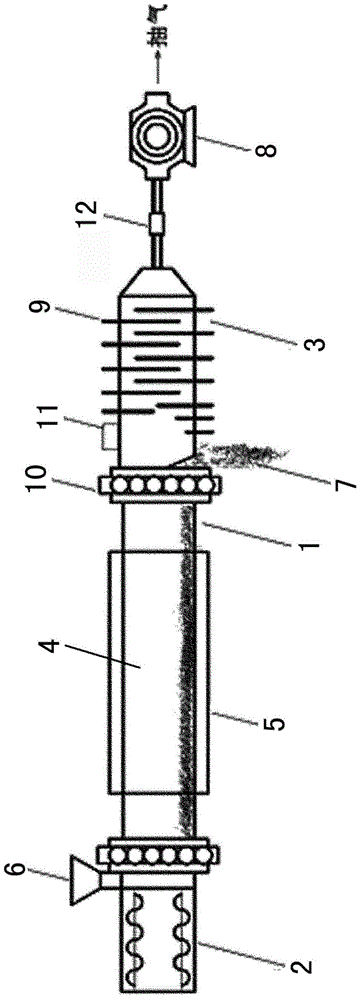

Method used

Image

Examples

Embodiment 1

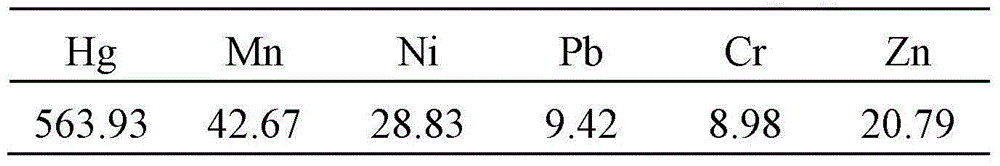

[0067] The mercury-contaminated soil samples came from a chlor-alkali production enterprise in Yunnan Province. The heavy metal content in the samples is shown in Table 6. The mercury content in the sample soil exceeded the limit of 1.5mg / kg for the mercury content in the third-grade soil in the "Soil Environmental Quality Standard" (GB15618-1995).

[0068] Table 1 The content of heavy metals in soil mg / kg

[0069]

[0070] The mercury-contaminated soil thermal desorption and mercury recovery treatment are as follows.

[0071] (1) Break the mercury-contaminated soil, pass it through a 7-mesh sieve, and add FeCl with 1.5% of the soil mass 3 , add water and stir well to make a slurry.

[0072] (2) Prepare an acidic aqueous solution (pH=3.5) with hydrochloric acid, and adjust the pH of the mud to about 7.5.

[0073] (3) Put the mud in an environment of 20°C to air-dry naturally, and the air-drying time is 18 hours.

[0074] (4) Use a roller compactor to crush the air-dried...

Embodiment 2

[0079] Mercury-contaminated soil samples came from a PVC manufacturer in Inner Mongolia Autonomous Region, and the heavy metal contents in the samples are shown in Table 2. The mercury content in the sample soil exceeded the limit of 1.5mg / kg for the mercury content in the third-grade soil in the "Soil Environmental Quality Standard" (GB15618-1995).

[0080] Table 2 The content of heavy metals in soil mg / kg

[0081]

[0082] The mercury-contaminated soil thermal desorption and mercury recovery treatment are as follows.

[0083] (1) Crush the mercury-contaminated soil, pass it through a 7-mesh sieve, and add 0.5% FeCl to the soil mass 3 , add water and stir well to make a slurry.

[0084] (2) Prepare an acidic aqueous solution (pH=3) with hydrochloric acid, and adjust the pH of the mud to about 7.0.

[0085] (3) Put the mud in an environment of 20°C to air-dry naturally, and the air-drying time is 16 hours.

[0086] (4) Use a roller compactor to crush the air-dried soil,...

Embodiment 3

[0091] The mercury-contaminated soil samples came from a primary mercury production enterprise in Shaanxi, and the heavy metal contents in the samples are shown in Table 4. The mercury content in the sample soil exceeded the limit of 1.5mg / kg for the mercury content in the third-grade soil in the "Soil Environmental Quality Standard" (GB15618-1995).

[0092] Table 3 The content of heavy metals in soil mg / kg

[0093]

[0094] The mercury-contaminated soil thermal desorption and mercury recovery treatment are as follows.

[0095] (1) Break the mercury-contaminated soil, pass it through a 7-mesh sieve, and add FeCl with 1.5% of the soil mass 3 , add water and stir well to make a slurry.

[0096] (2) Prepare an acidic aqueous solution (pH=3) with hydrochloric acid, and adjust the pH of the mud to about 7.0.

[0097] (3) Place the mud in an environment of 20°C to air-dry naturally, and the air-drying time is 24 hours.

[0098] (4) Use a roller compactor to crush the air-drie...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com