Preparation method of alloy zinc dust special for mercury-free batteries

A technology of alloy zinc powder and battery, which is applied to battery electrodes, circuits, electrical components, etc., can solve problems such as environmental pollution, and achieve the effects of convenient equipment operation, low production cost, and reduced hydrogen evolution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

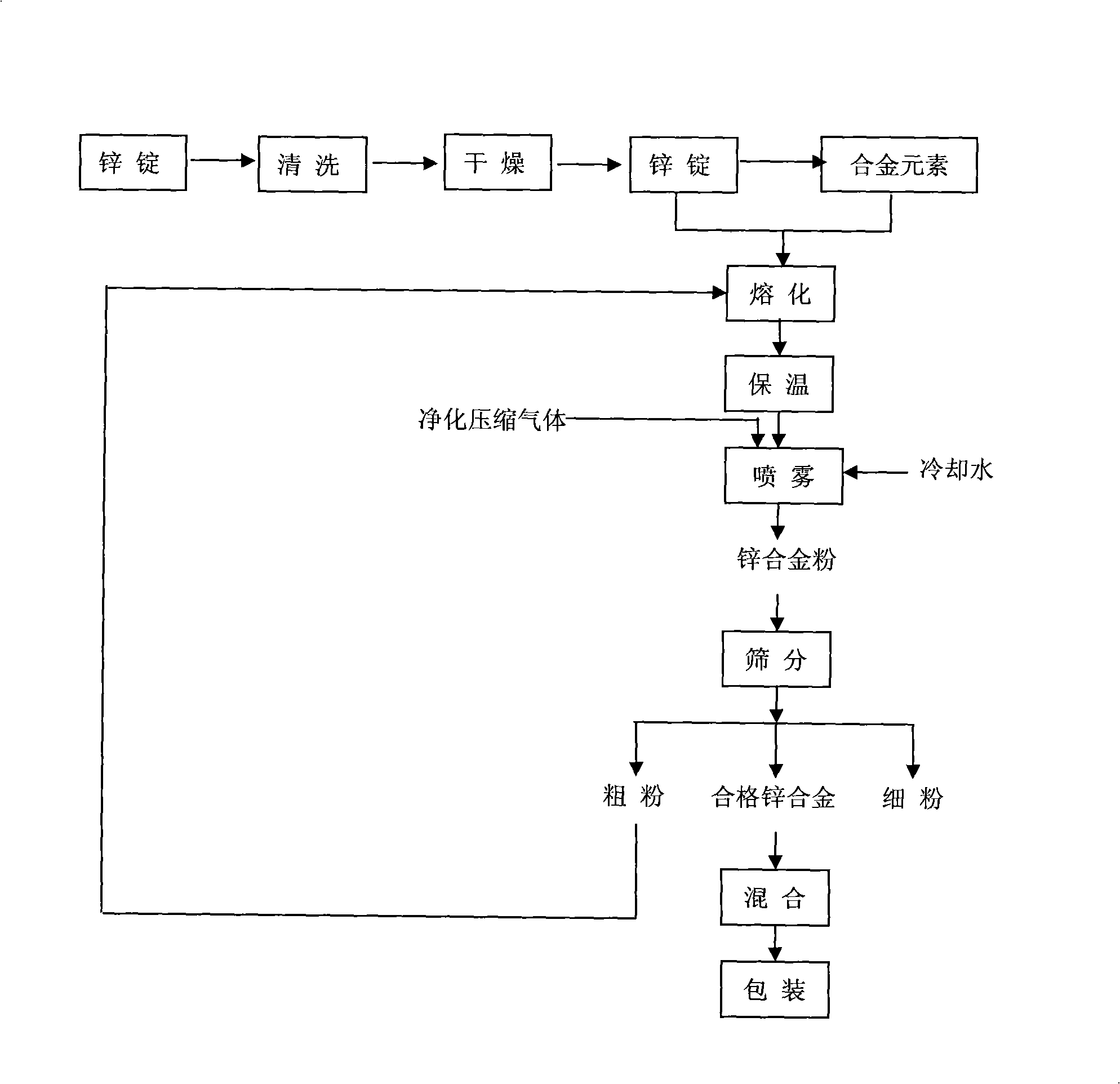

[0020] Example 1 as figure 1 Shown: a kind of preparation method of alloy zinc powder special for mercury-free battery, it is characterized in that: its production process comprises:

[0021] 1) Wash and dry the high-purity zinc ingots for later use.

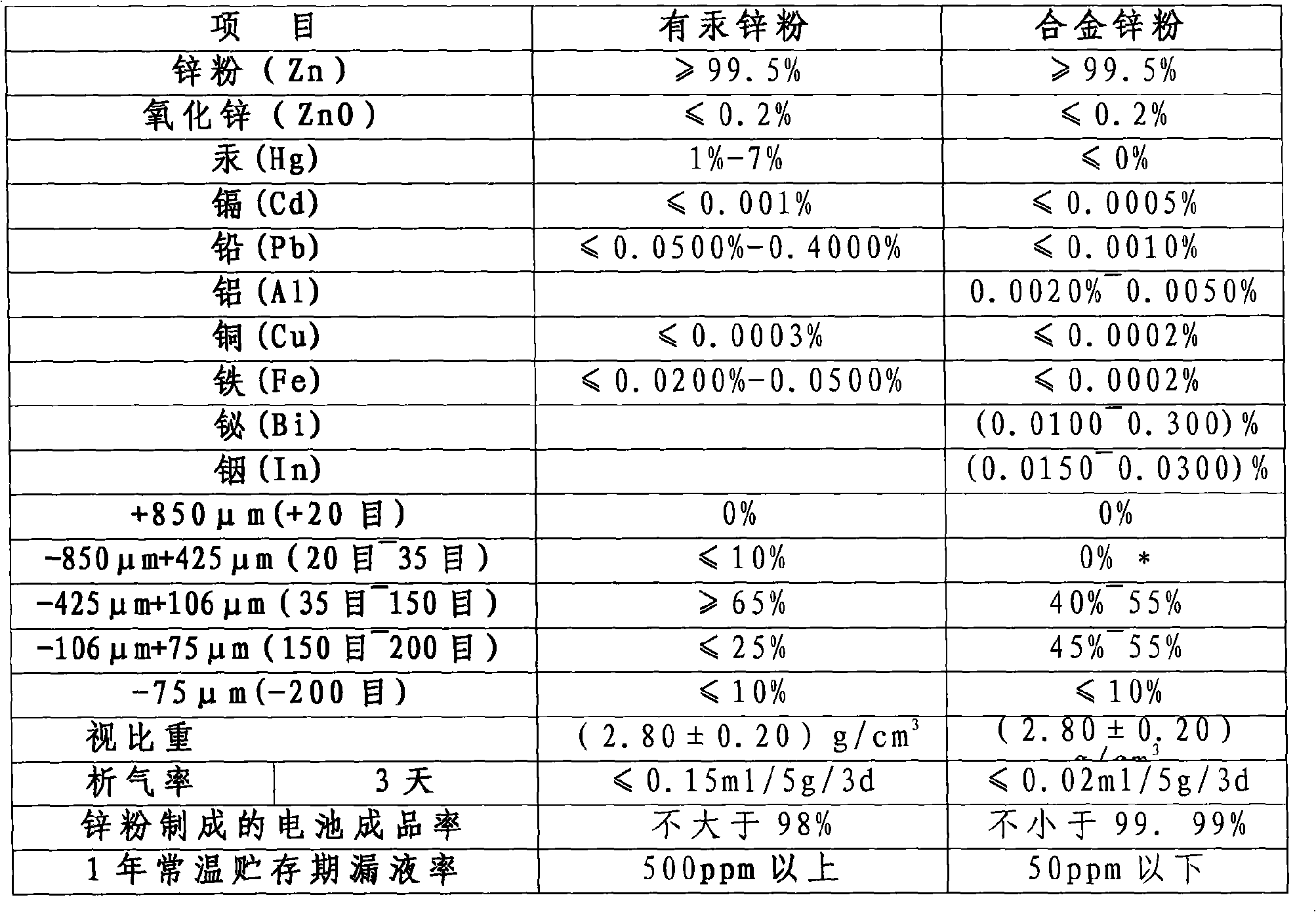

[0022] 2) Put the high-purity powdered indium, bismuth, and aluminum of the added elements into the bottom of the graphite crucible of the power frequency induction furnace, and then put the dried high-purity zinc ingots on the top of the added elements; 350 parts by weight of zinc ingots, 0.105 parts by weight of indium Parts by weight, 0.105 parts by weight of bismuth, 0.0105 parts by weight of aluminum; the content of zinc in the high-purity zinc ingot is greater than 99.99%, and the content of impurity iron is less than 1ppm; the content of indium in the high-purity indium powder is greater than 99.99%, and the content of bismuth in the high-purity The content is greater than 99.99%, and the aluminum content in high-purity ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com