Smoke gas catalysis adsorption cooperated demercuration device and method

An absorption device and mercury removal technology, which is applied in the fields of chemical industry, cement, power plant, metal smelting, and petroleum refining, can solve the problems of reduced mercury oxidation capacity, high dependence on chlorine content, difficult conversion, etc., and achieves convenient operation and low cost. , The effect of high mercury removal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] Example 1MnOx / Al 2 O 3 Catalytic mercury removal

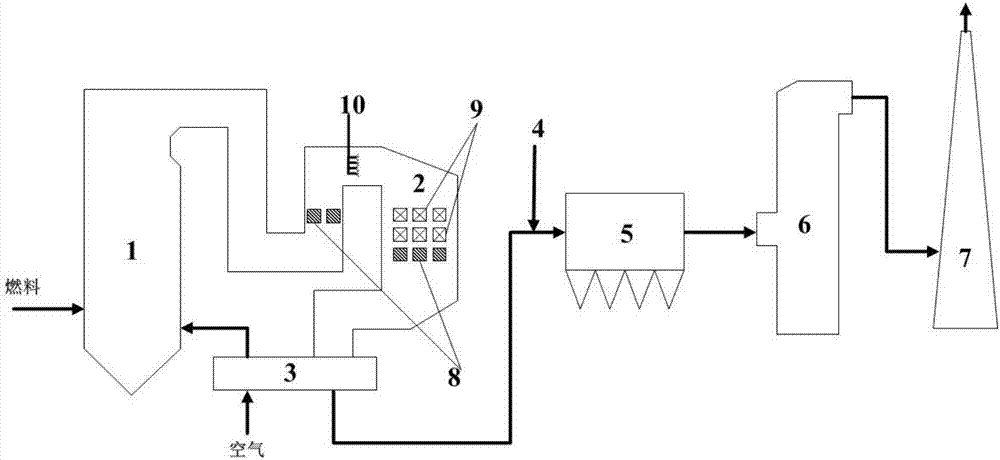

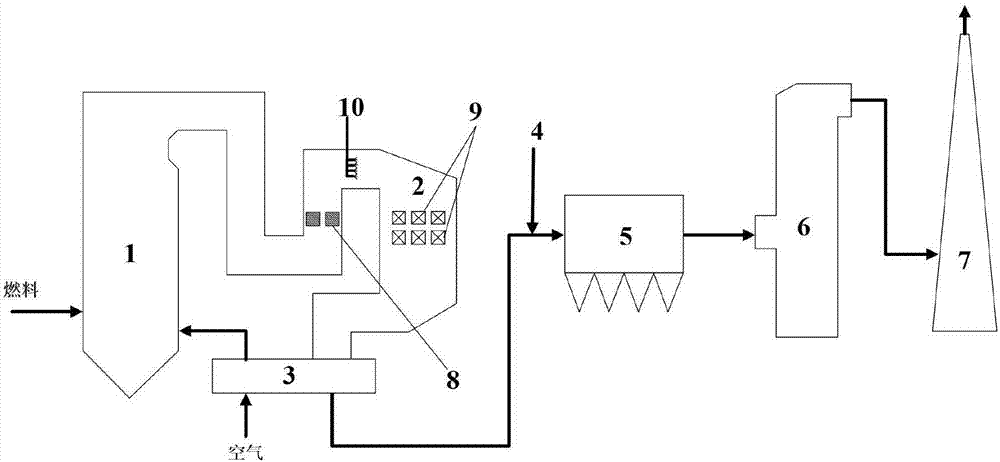

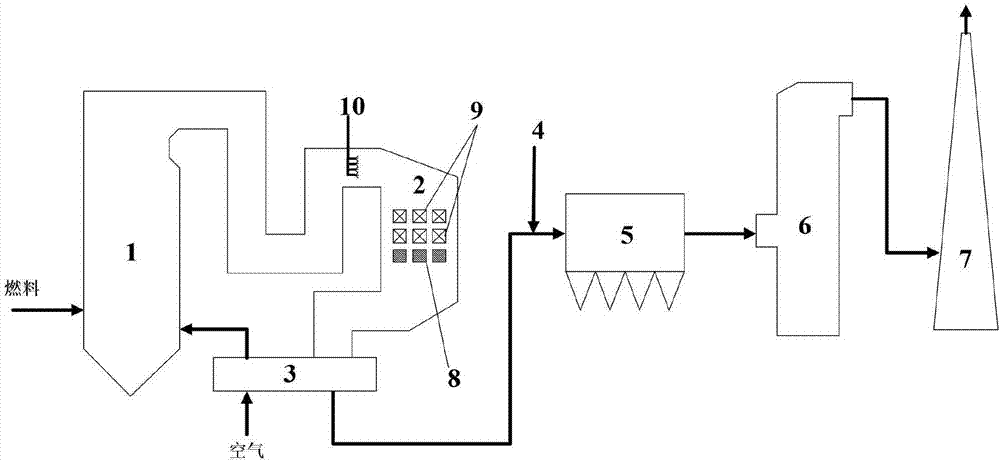

[0045] As attached figure 2 As shown, the MnOx / Al prepared by combining the dipping method and the sol-gel method in the flue upstream of the ammonia injection grid 10 2 O 3 Mercury removal catalyst, in which MnOx loading is 10wt%, and the reaction space velocity of mercury removal catalyst is 15000h -1 , HC1 concentration is 20ppm, reaction temperature is 300℃, and the other conditions are the same as the reference case. As a result, the mercury removal rate of the system reaches 90%; image 3 As shown, put MnOx / Al 2 O 3 The mercury removal catalyst is loaded downstream of the denitration catalyst layer 9, wherein the MnOx loading amount is 1wt%, and the mercury removal catalyst reaction space velocity is 5000h -1 , HC1 concentration is 20ppm, reaction temperature is 380°C, and other conditions are the same as in Example 1. As a result, the mercury removal rate of the system reaches 85%.

Embodiment 2

[0046] Example 2CoOx / TiO 2 Catalytic mercury removal

[0047] As attached figure 2 As shown, the upstream flue of the ammonia injection grid 10 is filled with CoOx / TiO produced by the impregnation method 2 Mercury removal catalyst, in which CoOx loading is 5wt%, reaction space velocity is 10000h -1 , HC1 concentration is 20ppm, reaction temperature is 320℃, and other conditions are the same as the reference case. As a result, the mercury removal rate of the system reaches 87%.

Embodiment 3

[0048] Example 3MnOx / Al 2 O 3 Catalytic adsorption synergistic mercury removal

[0049] As attached figure 2 As shown, the MnOx / Al prepared by the combination of the upstream flue filling and dipping method and the sol-gel method of the ammonia injection grid 10 2 O 3 Mercury removal catalyst, in which MnOx loading is 5wt%, reaction space velocity is 10000h -1 , HC1 concentration 20ppm, reaction temperature 320℃, adsorbents are activated carbon and Br-loaded modified activated carbon, the amount of carbon injection is determined by the weight ratio of activated carbon: total mercury in flue gas 5000:1, and the injection amount of modified activated carbon is modified Activated carbon: The weight ratio of total mercury in the flue gas is determined at 1000:1, and the other conditions are the same as the reference case. Results The mercury removal rate of the system reached 91.5% and 92% respectively.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com