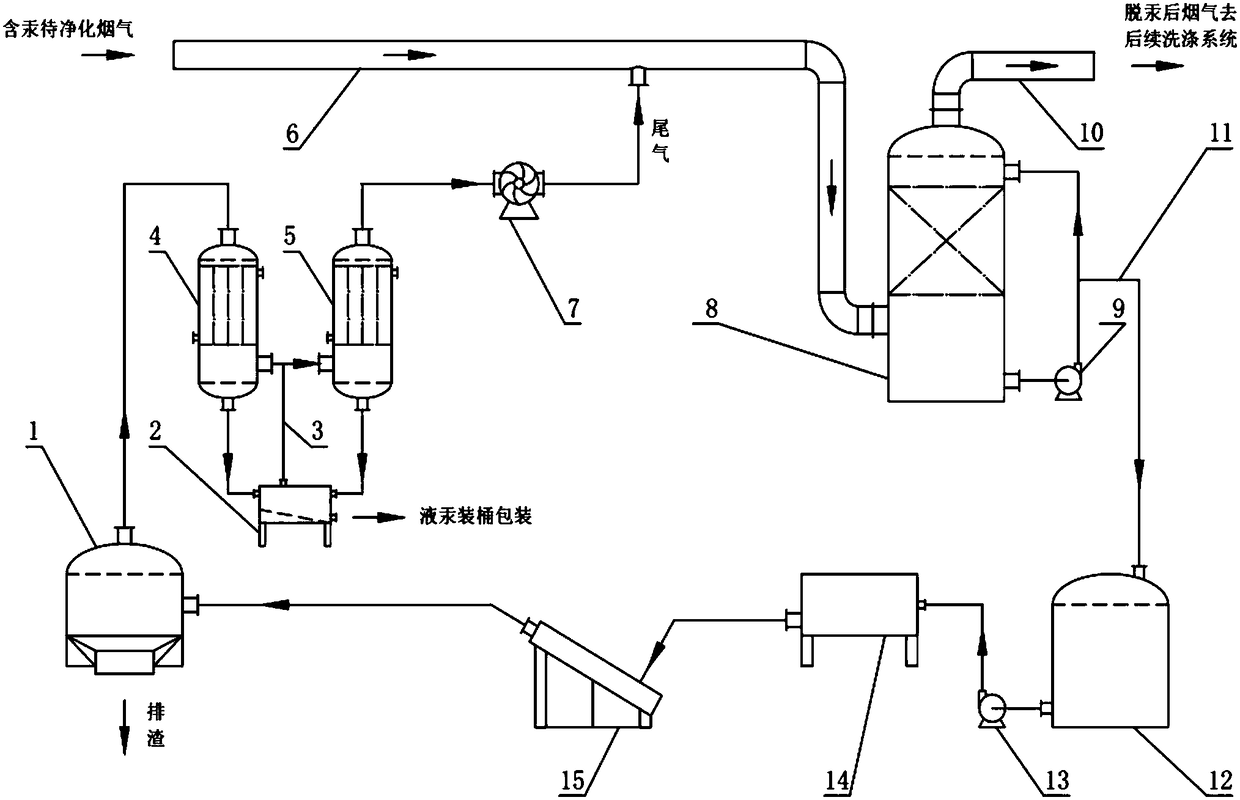

Method for recovering mercury in situ from mercury fume in non-ferrous metal metallurgy

A technology for non-ferrous metals and smelting flue gas, which is applied in the field of smelting flue gas treatment. It can solve the problems of high environmental pollution hazards, waste of mercury resources, and high cost of external transportation, so as to improve the efficiency of condensation collection and recovery, reduce production costs, and avoid pollution. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

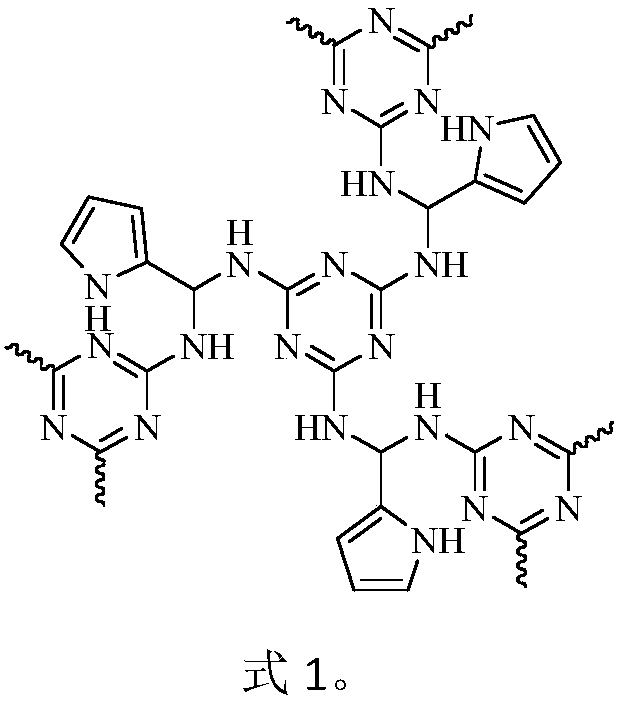

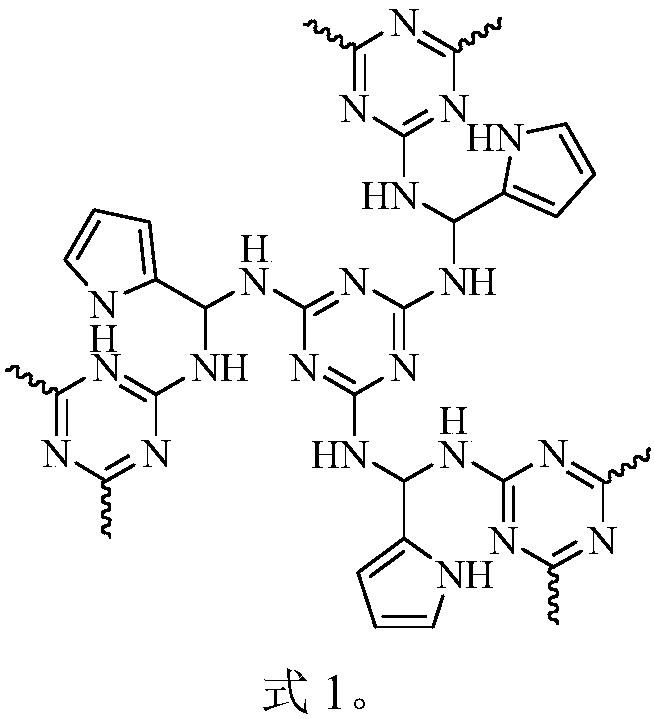

[0050] (1) Add mercury removal slurry containing melamine polymer material mercury removal agent (mass percentage concentration is about 11%) into the purification system, the slurry circulates in the purification system, and passes through the mercury removal agent at a temperature of about 100°C The chelation reaction with mercury captures and solidifies the mercury in the flue gas, and the purification efficiency can reach more than 90%.

[0051] (2) Through the detection of the amount of slurry taken, when the mercury content of the mercury removal agent reaches more than 5%, the amount of mercury-containing sewage sludge drawn from the purification system is about 0.5m 3 , The measured solid content was 11.8%.

[0052] (3) After the flocculation and concentration reaction, the concentrated mercury-containing acid mud is dehydrated to obtain 140 kg of mercury-containing sludge, and the measured moisture content is 60.0%. The mercury content in the dry residue is 6.02%.

...

Embodiment 2

[0062] (1) Add mercury removal slurry containing melamine polymer material mercury removal agent (mass percentage concentration is about 11%) into the purification system, the slurry circulates in the purification system, and passes through the mercury removal agent at a temperature of about 50°C The chelation reaction with mercury captures and solidifies the mercury in the flue gas, and the purification efficiency can reach more than 90%.

[0063] (2) Through the detection of the amount of slurry, when the mercury content of the mercury removal agent reaches more than 10%, the amount of mercury-containing acid sludge drawn from the mercury removal system is about 0.5m 3 , Solid content 12.5%.

[0064](3) After flocculation and concentration reaction, the concentrated mercury-containing acid mud is dehydrated to obtain 153.6 kg of mercury-containing sludge, and the moisture content is about 59.3%. The mercury content in the dry residue is 10.72%.

[0065] (4) Mix the mercury...

Embodiment 3

[0074] (1) Add mercury removal slurry containing melamine polymer material mercury removal agent (mass percentage concentration is about 11%) into the purification system, the slurry circulates in the purification system, and passes through the mercury removal agent at a temperature of about 150°C The chelation reaction with mercury captures and solidifies the mercury in the flue gas, and the purification efficiency can reach more than 90%.

[0075] (2) Through the detection of the amount of slurry taken, when the mercury content reaches more than 20%, the amount of mercury-containing acid sludge drawn from the mercury removal system is about 0.5m 3 , Solid content 10.5%.

[0076] (3) After the flocculation and concentration reaction, the concentrated mercury-containing acid mud was dehydrated to obtain 130.9 kg of mercury-containing sludge, and the moisture content was measured to be about 61.1%. The mercury content in the dry residue is 25.33%.

[0077] (4) Mix mercury-con...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com