Efficient and economic mercury-containing waste water treatment method

A waste water treatment and economical technology, applied in water/sewage multi-stage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc., can solve the problems of difficult resin recycling, large investment in treatment equipment and high treatment cost, Achieve the effect of low cost, wide application range and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

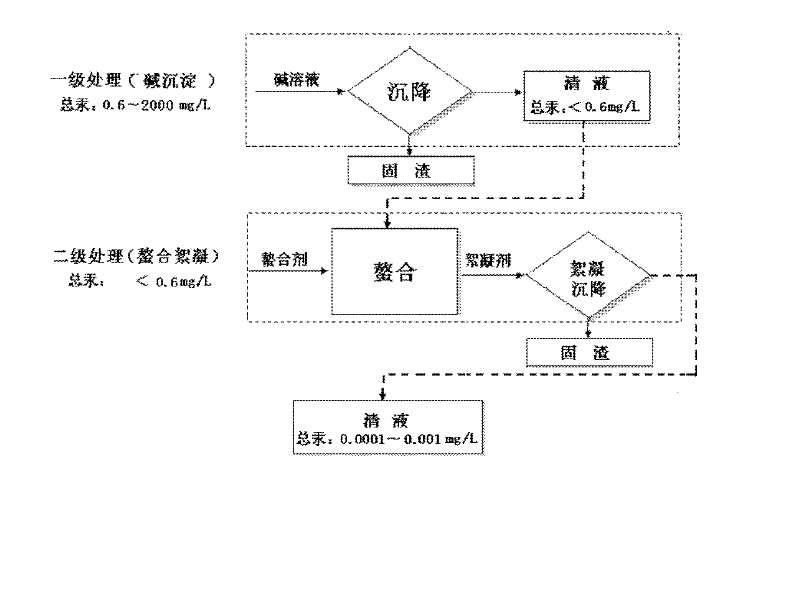

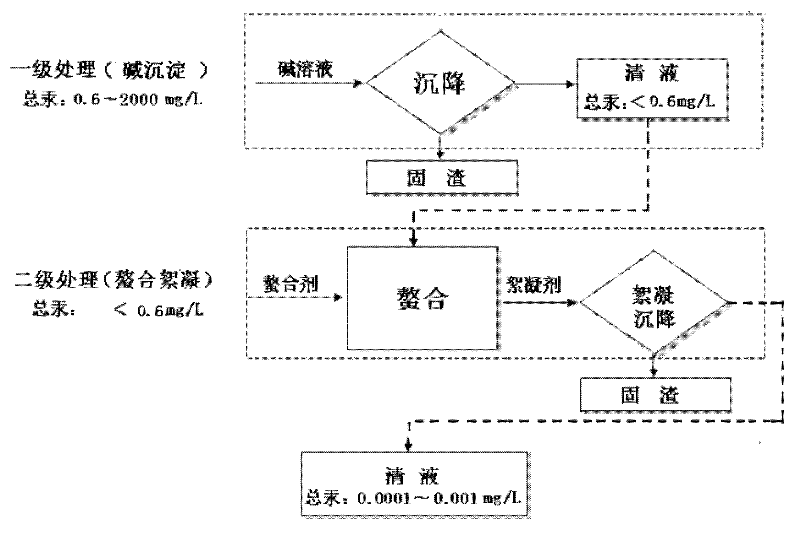

Method used

Image

Examples

Embodiment 1

[0012] Example 1 Acidic wastewater with a total mercury concentration of 50mg / L~200mg / L

[0013] The total mercury content of the sample wastewater before treatment is 150~200mg / L, and the hydrochloric acid content is 10%~15%. Add solid sodium hydroxide or lime milk to make the pH value of the water between 9~13. After mixing, mercury precipitates in the water and separated. The total mercury content of the clear liquid is less than 0.6mg / L.

[0014] The pH value of the clear liquid is between 9-13, add dithiocarbamic acid polymer DTCR solution (dithiocarbamic acid content 10%-15%) according to 0.02%~0.2% of the clear liquid volume, and adjust after mixing. When the pH value is between 3 and 7, the mercury in the solution is chelated and precipitated. Add a 10% ferric chloride solution flocculant with a mass fraction of 0.001 to 0.01 according to the volume ratio of the clear liquid, and separate the liquid and solid to obtain the treated clear liquid. The total mercury content me...

Embodiment 2

[0015] Example 2 Acidic wastewater with a total mercury concentration of 30mg / L~50mg / L

[0016] Before the sample wastewater treatment, the total mercury content is 30mg / L~50mg / L, the pH value is 1~3, add the calcium carbide slag slurry water clear liquid, adjust the pH value between 9~13, after mixing, precipitate mercury precipitation, and separate the clear The total amount of mercury in the liquid is less than 0.6 mg / L.

[0017] The pH value of the clear liquid is between 9 and 13, add 0.01% to 0.1% of the weight of the clear solution modified dithiocarbamate starch (dithiocarbamate content 20-30%), adjust the pH value between 3-7 At the same time, the mercury in the solution was chelated and precipitated. Add a 10% polyferric sulfate solution with a mass fraction of 0.001 to 0.01 in the volume ratio of the clear liquid. The treated clear liquid was obtained by liquid-solid separation. The total mercury content was determined to be 0.0001 by cold atomic absorption method. ~0.0...

Embodiment 3

[0018] Example 3 Alkaline wastewater with a total mercury concentration of 2.2mg / L~2.8mg / L

[0019] The total mercury content of the sample wastewater before treatment is 2.2mg / L~2.8mg / L, the pH value is 9~10, sodium sulfide is added, the pH value is adjusted between 9~13, the mercury precipitates out after mixing, and the clear liquid is separated Total mercury is less than 0.6mg / L

[0020] The pH value of the clear liquid is between 9-13, and the TMT solution of trimercaptotriazine trisodium (TMT content 10%-15%) is added according to 0.02%~0.2% of the volume of the clear liquid. After mixing, adjust the pH value at 3~ Between 7, the mercury in the solution was chelated and precipitated. Add 10% polyaluminum chloride with a mass fraction of 0.001 to 0.01 in the volume ratio of the clear liquid. The clear liquid obtained from the liquid-solid separation was measured by cold atomic absorption method to determine the total mercury content of 0.0001 mg / L~0.001mg / L.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com