Method for removing mercury from smoke in coal fired power plant and mercury removing agent used by same

A technology of coal-fired power plants and mercury removal agents, applied in the field of flue gas purification, can solve problems such as high operating costs, difficult reactions, secondary pollution, etc., and achieve high mercury removal efficiency, non-corrosive equipment, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

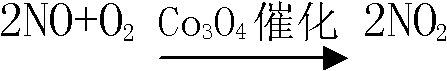

[0023] Embodiment 1: the composition of mercury removal agent: the industrial grade Co of 5 weight parts 3 o 4 and 1000 parts by weight of technical grade CuCl 2 2H 2 O.

[0024] Before adding mercury removal agent: the load in the limestone-gypsum wet desulfurization system is 280MW, SO 2 The inlet concentration is 3000ppm, the desulfurization efficiency is 95%, the denitrification rate is 10%, and the mercury removal rate is 20%.

[0025] Adopt the mercury removal method of the present invention: add the above-mentioned mercury removal agent into the pit of the limestone-gypsum wet desulfurization system, dissolve with the existing limestone slurry in the pit, so that the concentration of the mercury removal agent in the total slurry is 500ppm, and then pump the slurry into the top of the absorption tower; the slurry containing the mercury removal agent is sprayed down in the absorption tower, and the flue gas containing sulfur dioxide that flows upstream is sprayed and ...

Embodiment 2

[0026] Embodiment 2: the composition of mercury removal agent: the industrial grade Co of 7 weight parts 3 o 4 and 1000 parts by weight of technical grade CuCl 2 2H 2 O.

[0027] Before adding mercury removal agent: the load in the limestone-gypsum wet desulfurization system is 330MW, SO 2 The inlet concentration is 3500ppm, the desulfurization efficiency is 92%, the denitrification rate is 15%, and the mercury removal rate is 40%.

[0028] Using the mercury removal method of the present invention: add the above-mentioned mercury removal agent to the pit of the limestone-gypsum wet desulfurization system, use the existing limestone slurry in the pit and add process water to dissolve, so that the mercury removal agent is in the total slurry The concentration in the mercury is 600ppm, and then the slurry is pumped into the top of the absorption tower with a pit pump; the slurry containing the mercury removal agent is sprayed down in the absorption tower, and the flue gas con...

Embodiment 3

[0029] Example 3: The composition of the mercury removal agent: 10 parts by weight of cobalt oxide and 1000 parts by weight of copper chloride.

[0030] Before adding mercury removal agent: the load in the limestone-gypsum wet desulfurization system is 330MW, SO 2 The inlet concentration is 5000ppm, the desulfurization efficiency is 90%, the denitrification rate is 20%, and the mercury removal rate is 30%.

[0031] Adopt the mercury removal method of the present invention: add the above-mentioned mercury removal agent into the limestone slurry used in the limestone-gypsum wet desulfurization system, the concentration of the mercury removal agent in the total slurry is 1000ppm, stir and mix; Sprayed into the absorption tower, the sprayed slurry directly contacts with the sulfur dioxide-containing flue gas countercurrently going up, and the absorption reaction takes place, and the reacted slurry is oxidized by the air blown by the oxidation fan. After stable operation, the desu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com