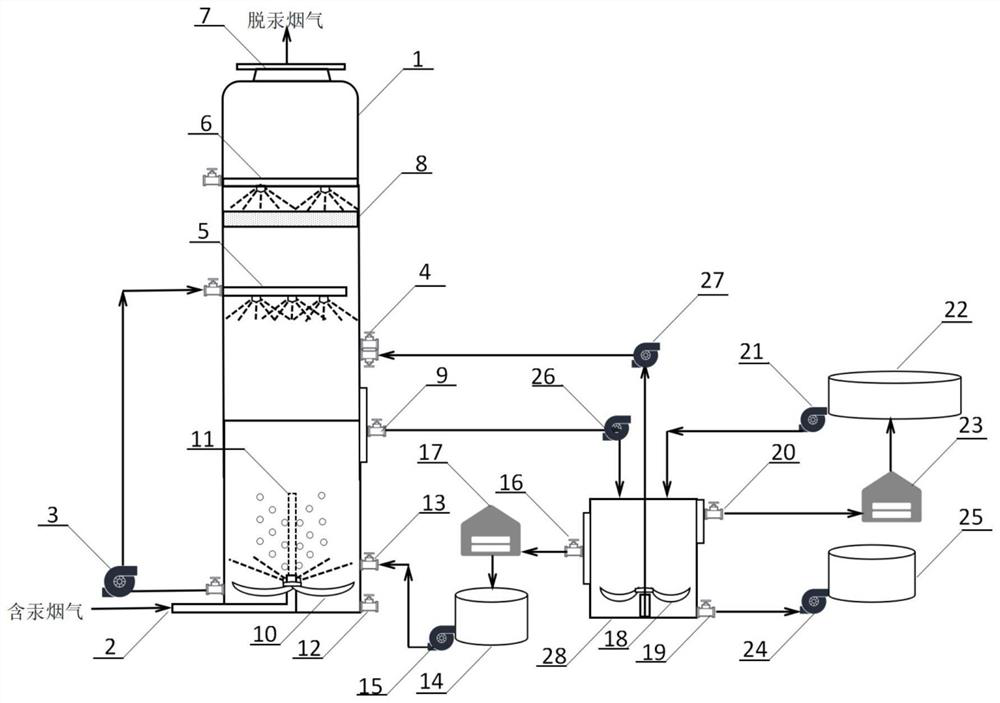

Stable suspension system for removing mercury in flue gas and recovery method of suspension system

A stable and systematic technology, applied in gas treatment, separation methods, chemical instruments and methods, etc., to achieve huge environmental benefits, avoid re-release, and long-lasting effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

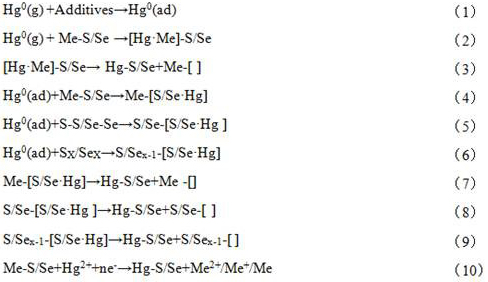

Method used

Image

Examples

Embodiment 1

[0048] At 25°C, add 1mL of neat polysiloxane additives with a viscosity of 500Pa.s to 100mL of washing liquid and stir, then add the synthesized copper sulfide to the washing liquid and stir at high speed for pretreatment. The temperature of the stable suspension system is 25°C, and the acidity is pH=7. A mercury meter is used to measure the mercury concentration in real time. The mass flow meter accurately controls the gas flow of each component to simulate the composition of the flue gas. The total gas flow is 1L / min. Initial Hg 0 The concentration is 1000±1μg / m 3 , in pure N 2 Under the atmosphere, within 48h, the suspension system has a 0 The removal efficiency is 98.1%. Using petroleum ether as an organic solvent to recover and separate the suspension system can realize the separation of polysiloxane additives and copper sulfide, and petroleum ether and polysiloxane additives can be recycled.

Embodiment 2

[0050] Add 1mL polysiloxane additive recovered from Example 1 to 100mL washing solution at 50°C and stir, then add the synthesized copper sulfide to the washing solution with high-speed stirring for pretreatment. The temperature of the stable suspension system is 5°C, and the acidity is pH=7. A mercury meter is used to measure the mercury concentration in real time. The mass flow meter accurately controls the gas flow of each component to simulate the composition of the flue gas. The total gas flow is 1L / min. Initial Hg 0 The concentration is 1000±1μg / m 3 , in a simulated flue gas atmosphere of 10% SO 2 , N 2 As a carrier gas, within 48 hours, the suspension system will 0 The removal efficiency is 97.3%. Using the petroleum ether recovered in Example 1 as an organic solvent to recover and separate the suspension system can realize the separation of polysiloxane additives and copper sulfide, and petroleum ether and polysiloxane additives can be recycled.

Embodiment 3

[0052] Add 0.05mL of neat polysiloxane additives with a viscosity of 100000Pa.s to 100mL washing liquid and stir at 20°C, then add synthetic iron sulfide to the washing liquid and stir at high speed for pretreatment. The temperature of the stable suspension system is 100°C, the acidity is 4mol / L sulfuric acid, and the mercury concentration is measured in real time with a mercury meter. The mass flow meter accurately controls the gas flow of each component to simulate the composition of the flue gas. The total gas flow is 1L / min , initial Hg 0 The concentration is 100±1μg / m 3 , in pure N 2 Under the atmosphere, within 96h, the suspension system has a 0 The removal efficiency is 99.3%. The separation of iron sulfide can be realized by using the petroleum ether recycled twice as an organic solvent to recover and separate the suspension system, and the petroleum ether can be recycled.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com