Patents

Literature

34results about How to "Reduce the cost of mercury removal" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

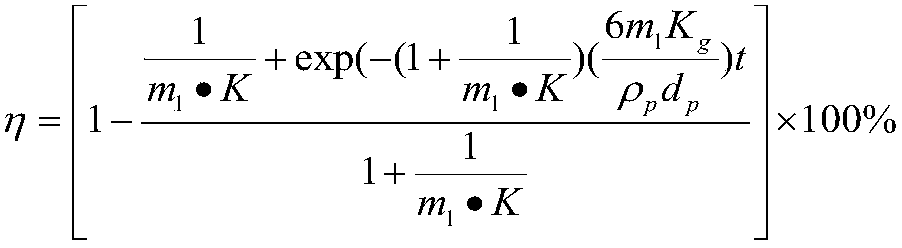

Method for removing elemental mercury in coal-fired flue gas

InactiveCN105233687AReduce the cost of mercury removalAchieve conversionDispersed particle separationRubidiumLanthanum

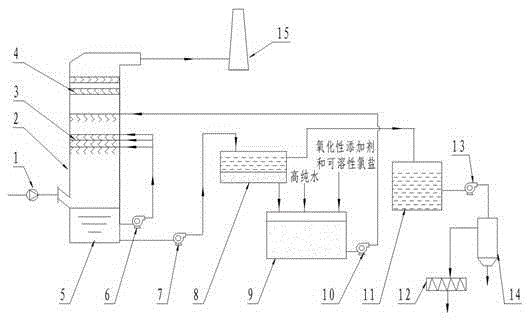

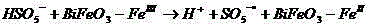

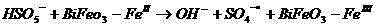

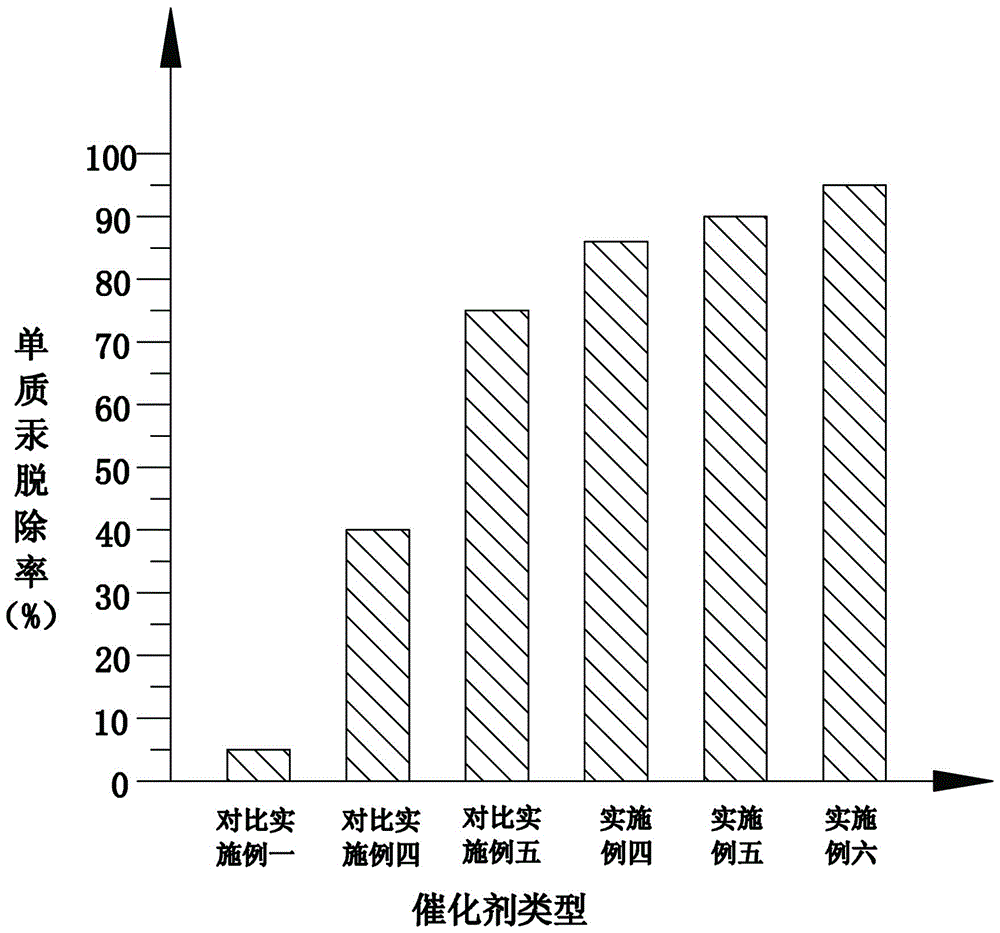

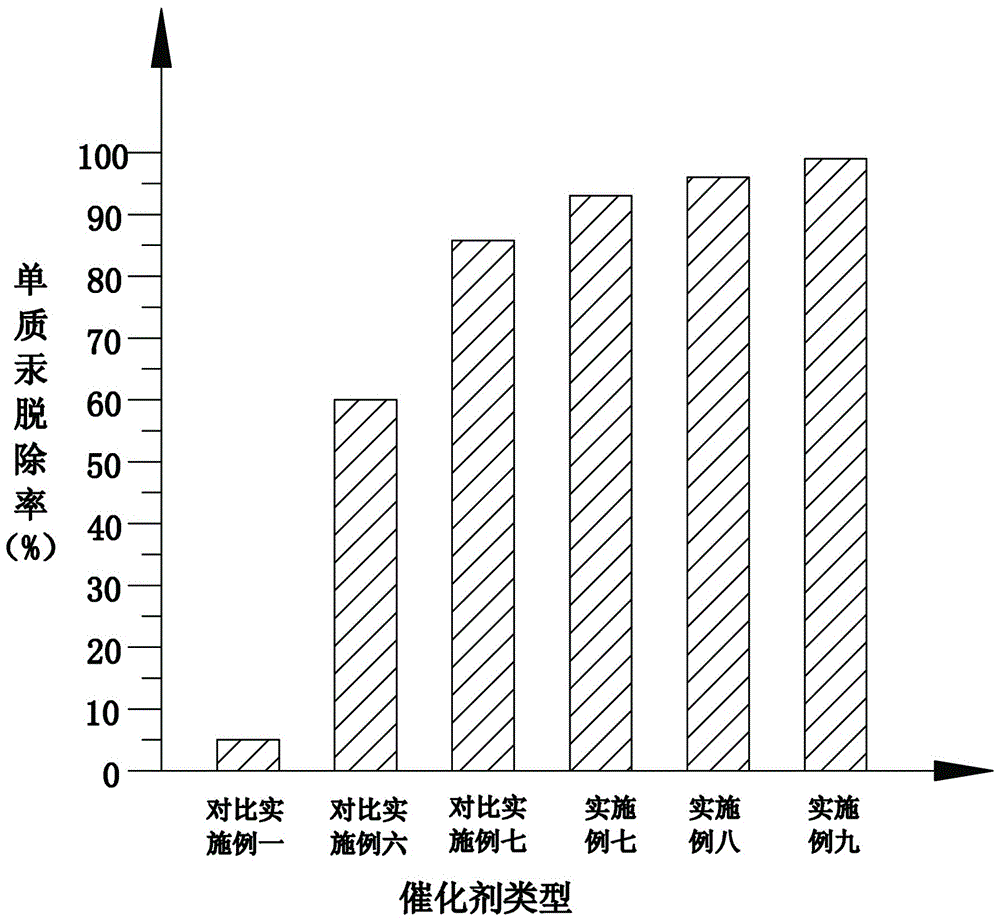

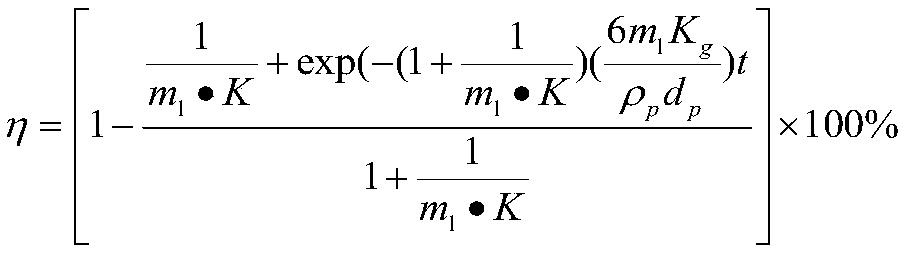

The invention discloses a method for removing elemental mercury in coal-fired flue gas. Removing is carried out in a spray absorber. A prepared absorbent is sprayed from the upper portion of the spray absorber for carrying out spraying on coal-fired flue gas introduced in from a smoke opening in the lower portion of the spray absorber, elemental mercury in the coal-fired flue gas sufficiently reacts with the absorbent, and conversion from the elemental mercury to divalent state mercury is achieved; the absorbent comprises an oxidation additive and a magnetic catalyst which have the mass ratio being 2-5:1, the oxidation additive is any one of or the combination of two or more of potassium peroxymonosulfate, sodium persulfate, sodium perborate and sodium percarbonate, and the catalyst is any one of or the mixture of two or more of bismuth ferrite, cobalt doped bismuth iron acid, cobalt / lanthanum doped bismuth ferrite, cobalt / strontium doped bismuth ferrite, cobalt / rubidium doped bismuth ferrite. The method has the advantages that the absorbent utilization rate is high, the catalyst can be repeatedly used, secondary pollution is avoided, operation is easy and convenient, running is stable, the product is easy to treat, and application and popularization are convenient.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

Composite magnetic visible light photocatalyst silver-silver halide-bismuth oxyhalide-cobalt ferrite and preparation method thereof

ActiveCN106732688AEfficient separationStrong oxidation abilityGas treatmentPhysical/chemical process catalystsElectron holeAdditive ingredient

The invention provides a composite magnetic visible light photocatalyst silver-silver halide-bismuth oxyhalide-cobalt ferrite and a preparation method thereof. The invention provides a recoverable magnetic visible light photocatalyst Ag-AgX-BiOX-CoFe2O4 (X is Cl or Br or I); the catalyst is formed by compounding simple substances Ag, AgX (X is Cl or Br or I), BiOX (X is Cl or Br or I) and CoFe2O4. Multiple ingredients are coupled, so that the effective separation of photo-induced electron hole pairs is facilitated; many strong oxidizing substances can be generated, so that the oxidization activity of the visible light photocatalyst can be enhanced; through the doping of a magnetic carrier of CoFe2O4, the visible light photocatalyst has the sufficient strong magnetic recovery capability; the multi-time circulation use can be realized, so that the smoke gas demercuration cost can be reduced; the environment-friendly performance of the visible light photocatalyst is improved.

Owner:HENAN POLYTECHNIC UNIV

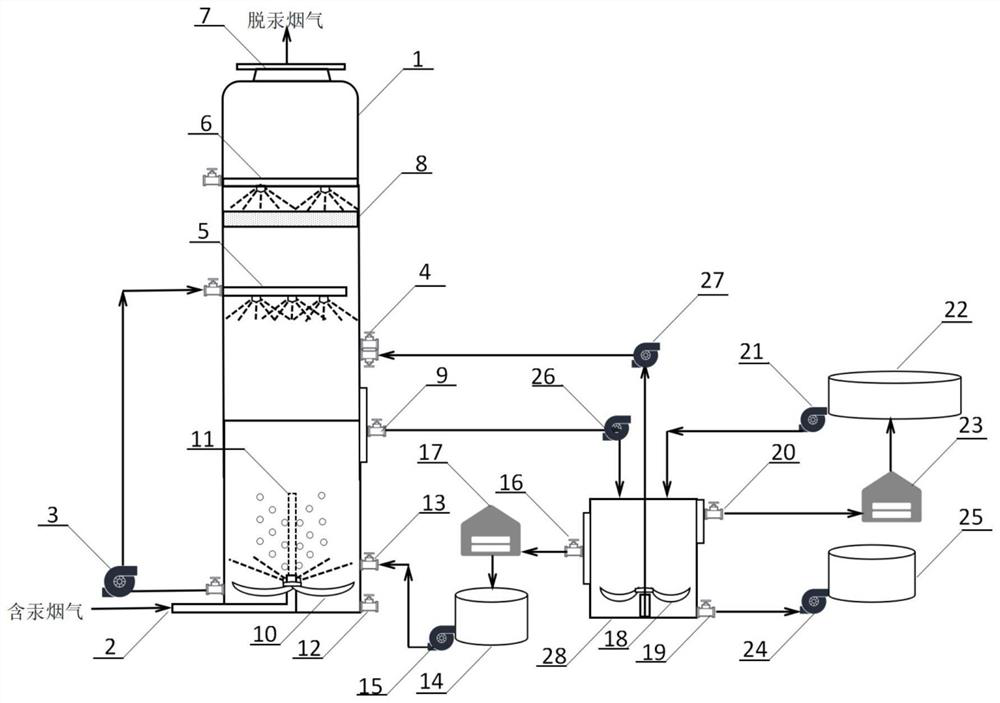

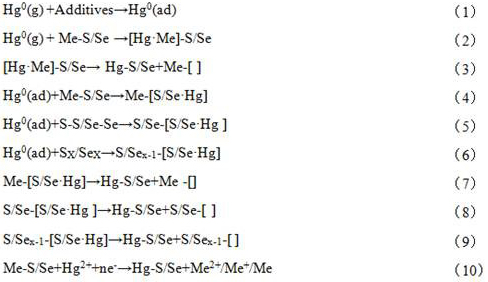

Normal-temperature and normal-pressure preparation method and application of metal selenide mercury adsorbent

PendingCN113231004AImprove adsorption capacityIncrease speedGas treatmentOther chemical processesSorbentCobalt

The invention discloses a normal-temperature and normal-pressure preparation method and application of a metal selenide mercury adsorbent. The metal selenide mercury adsorbent is prepared at normal temperature and normal pressure by adopting a precipitation method. The metal selenide mercury adsorbent comprises a compound formed by selenium and one or more of chromium, manganese, iron, copper, cobalt, nickel, zinc, molybdenum, silver and cadmium and a composite of the compound, unstable mercury is converted into stable mercury selenide, mercury in industrial tail gas or by-products of fire coal, metallurgy, waste incineration, cement production and the like is removed, mercury enriched in mercury-containing articles for daily use is absorbed, the recovery and reutilization of mercury resources are realized, and mercury to be treated can exist in the forms of a simple substance state, a free state and / or a compound state and the like. As the metal selenide has extremely high mercury adsorption capacity and adsorption rate, realization of large-scale preparation of the metal selenide under normal temperature and pressure conditions has great significance on mercury pollution prevention and control, and the corresponding technology has wide market application prospects.

Owner:CENT SOUTH UNIV

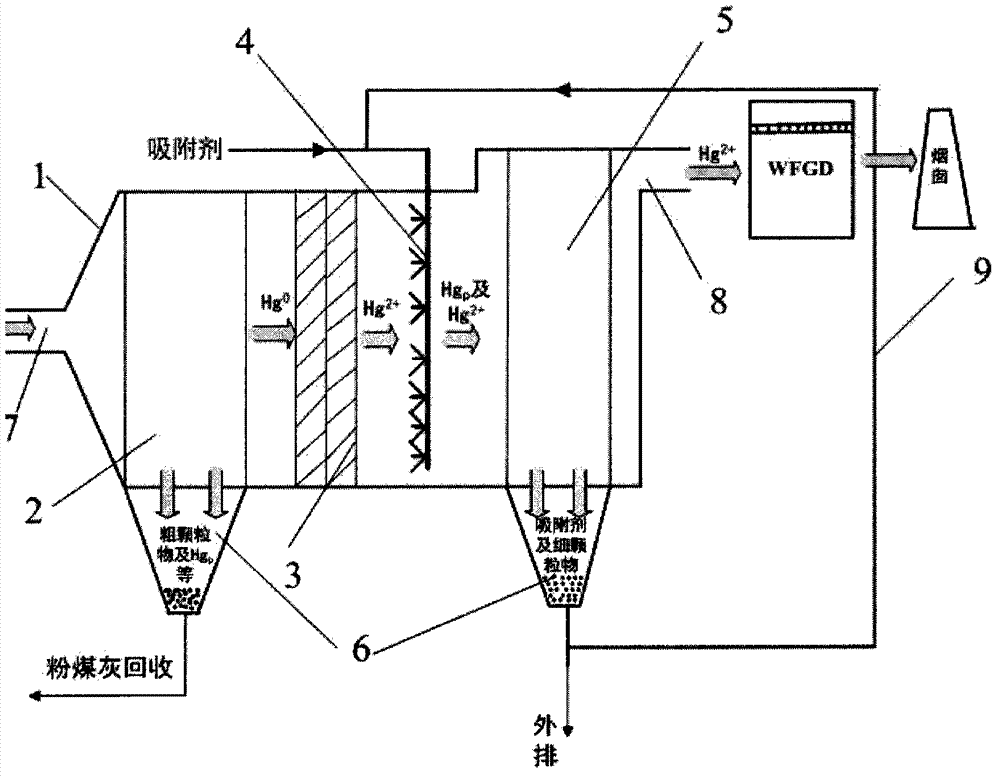

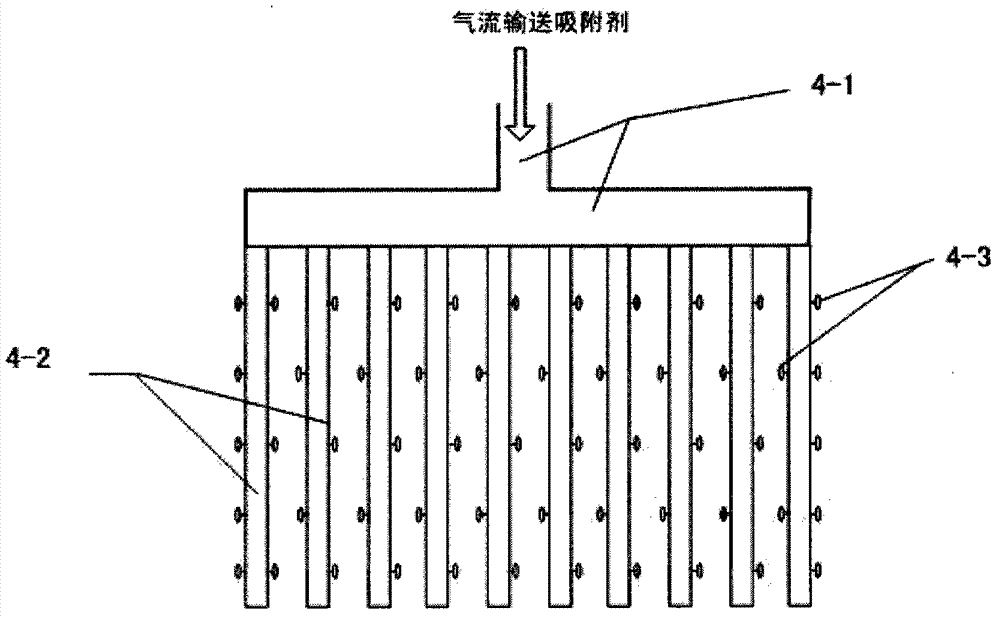

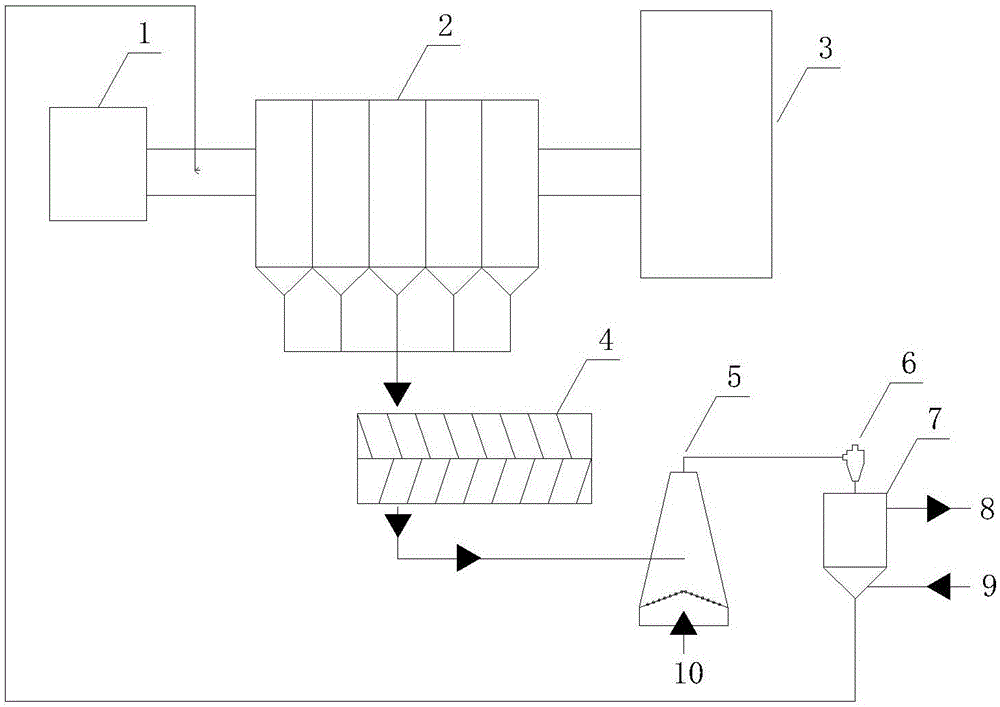

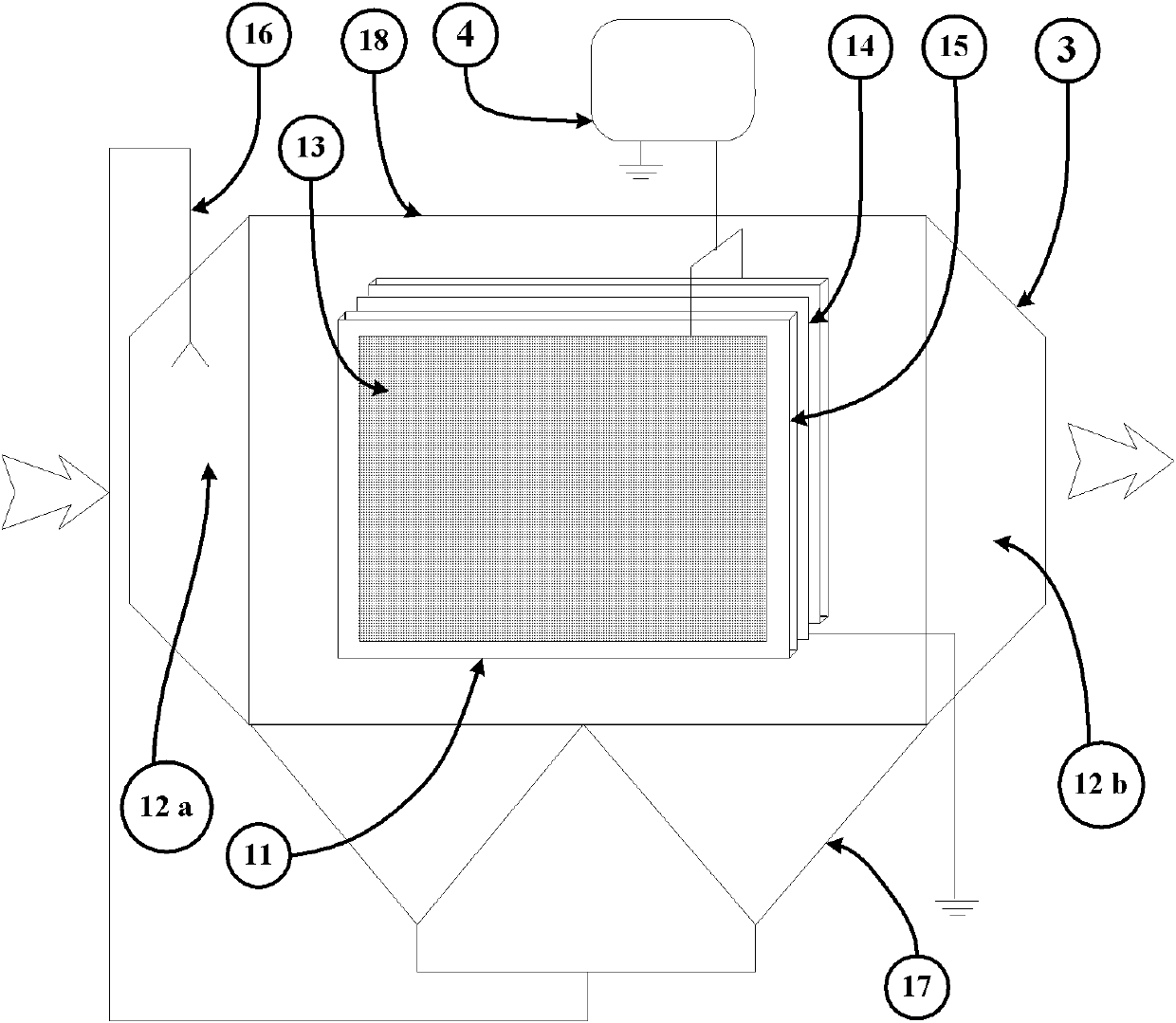

Method and device for performing combined removal on boiler flue gas particulates and heavy metals

InactiveCN104740983AEfficient mercury removalEfficient removalCombination devicesParticulatesSorbent

The invention discloses a method and a device for performing combined removal on boiler flue gas particulates and heavy metals. The device comprises an electrostatic precipitation area, a heavy metal catalytic oxidation area, an adsorbent injection area and a bag-type dust removal area. The method comprises the following steps: allowing boiler flue gas to pass through the electrostatic precipitation area, efficiently capturing the particulates and the particle state heavy metals such as mercury and arsenic by virtue of an electrostatic precipitator, allowing the flue gas to pass through a mercury catalytic oxidizer fixed bed, converting zero-valent mercury into divalent mercury in the flue gas, injecting activated carbon behind the catalytic oxidizer fixed bed so as to adsorb and remove the heavy metals such as mercury and arsenic, and allowing the activated carbon adsorbing the heavy metals and escaping fly ash to enter a bag area so as to be captured. Original quality coal ash is discharged by an electric area ash bucket, the activated carbon adsorbing the heavy metals and a small amount of coal ash are discharged by a bag-area ash bucket, a small amount of discharge is realized, and most of a mixture circulates to a pipeline to be injected into the flue gas to be recycled. According to the device and the method provided by the invention, the combined removal on the particulates and the heavy metals can be effectively realized, and the efficiency of removing the heavy metals in the coal-fired flue gas is greatly improved.

Owner:ELECTRIC POWER RES INST OF GUANGDONG POWER GRID +1

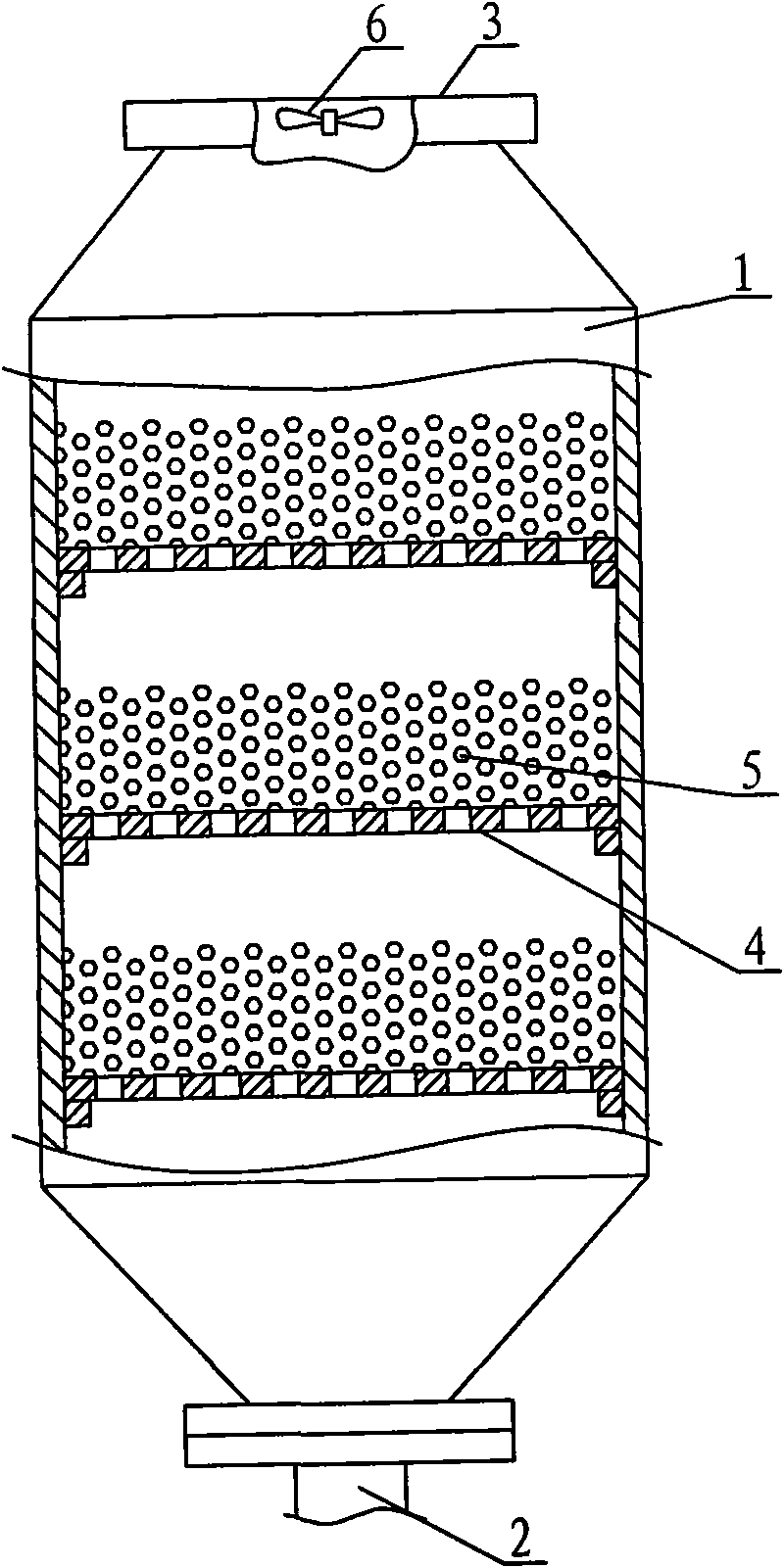

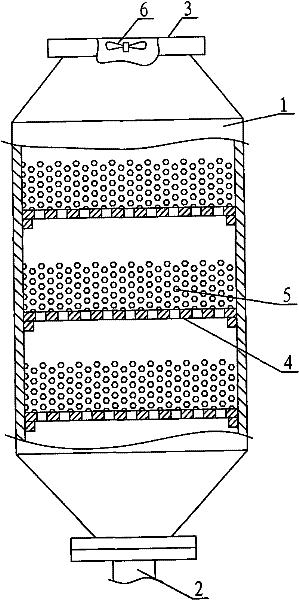

Flue gas mercury removal device

InactiveCN101844024AImprove mercury removal efficiencyLow implementation costDispersed particle separationFlue gasOperational maintenance

The invention discloses a flue gas mercury removal device, comprising a reactor casing, the lower part of which is provided with a gas inlet and the upper part of which is provided with a gas outlet. The flue gas mercury removal device is characterized in that, porous support plates at three layers are arranged between the gas inlet and the gas outlet of an inner cavity of the reactor casing, and each support plate is provided with an adsorptive filler layer. Compared with the prior art, the flue gas mercury removal device has the advantages of high mercury removal efficiency and convenient implementation cost; in addition, the porous support plates at three layers are arranged, so a temporary maintenance platform during maintenance is not required and operational maintenance staff can stand on a flue gas rectifier plate to maintain and replace internal parts, thus the device also has the advantage of convenient maintenance.

Owner:CHONGQING UNIV

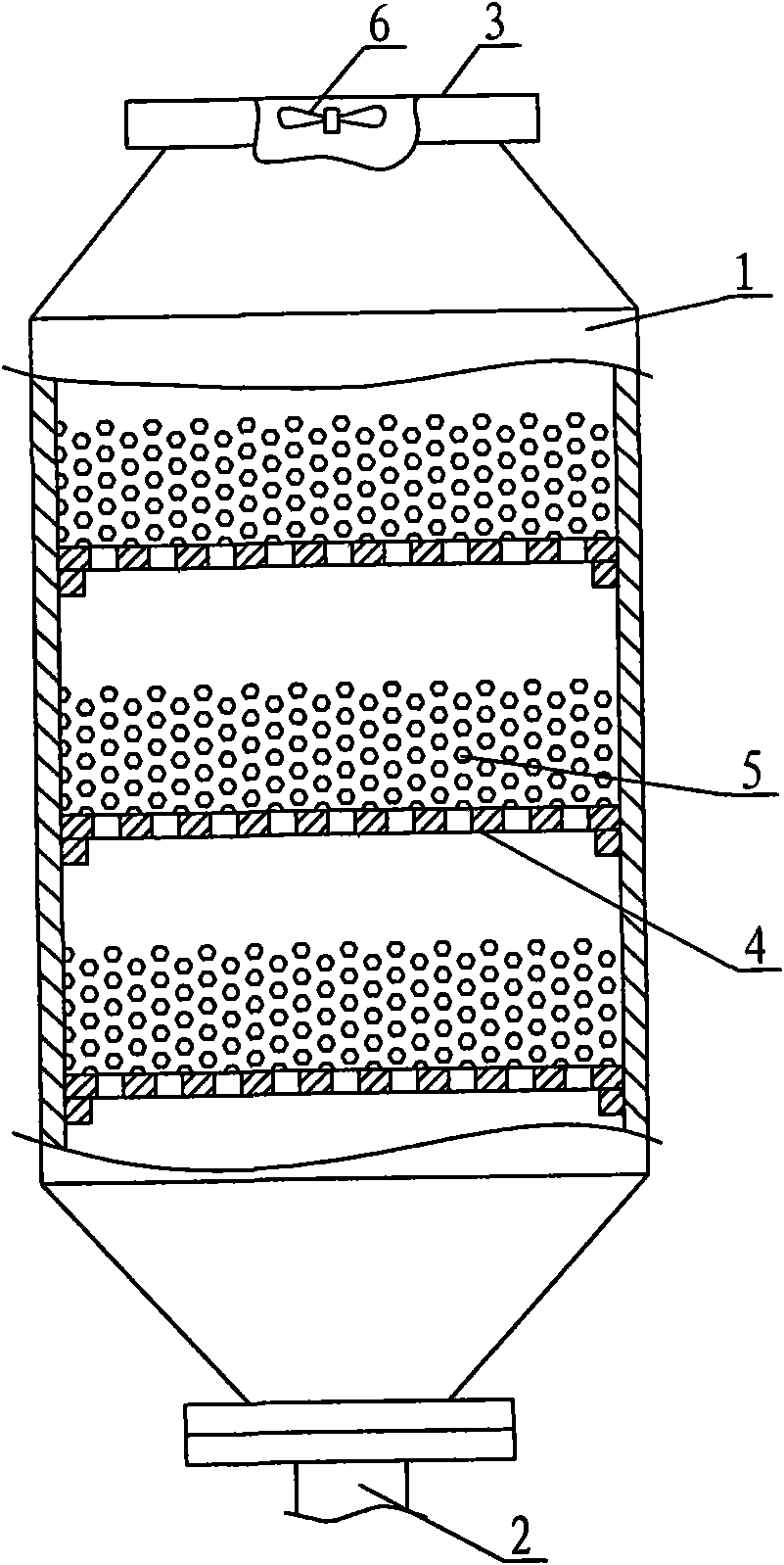

Stable suspension system for removing mercury in flue gas and recovery method of suspension system

ActiveCN112755764AImprove mercury removal efficiencyLarge capacityGas treatmentDispersed particle separationFlue gasControl system

The invention discloses a stable suspension system for removing mercury in flue gas and a recovery method of the suspension system. Metal sulfur, a selenide mercury removal agent and an additive are pretreated to form a stable suspension, the mercury-containing flue gas is in contact with the suspension, gaseous mercury (Hg0) is converted into stable mercuric sulfide or mercury selenide, and efficient removal of gaseous mercury in the flue gas is achieved. According to the method, existing pollutant control systems in various industries can be utilized, and the cost is low; the suspension system is simple to recover and separate and can be recycled; mercury can be recycled as a product; and the market prospect is wide.

Owner:CENT SOUTH UNIV

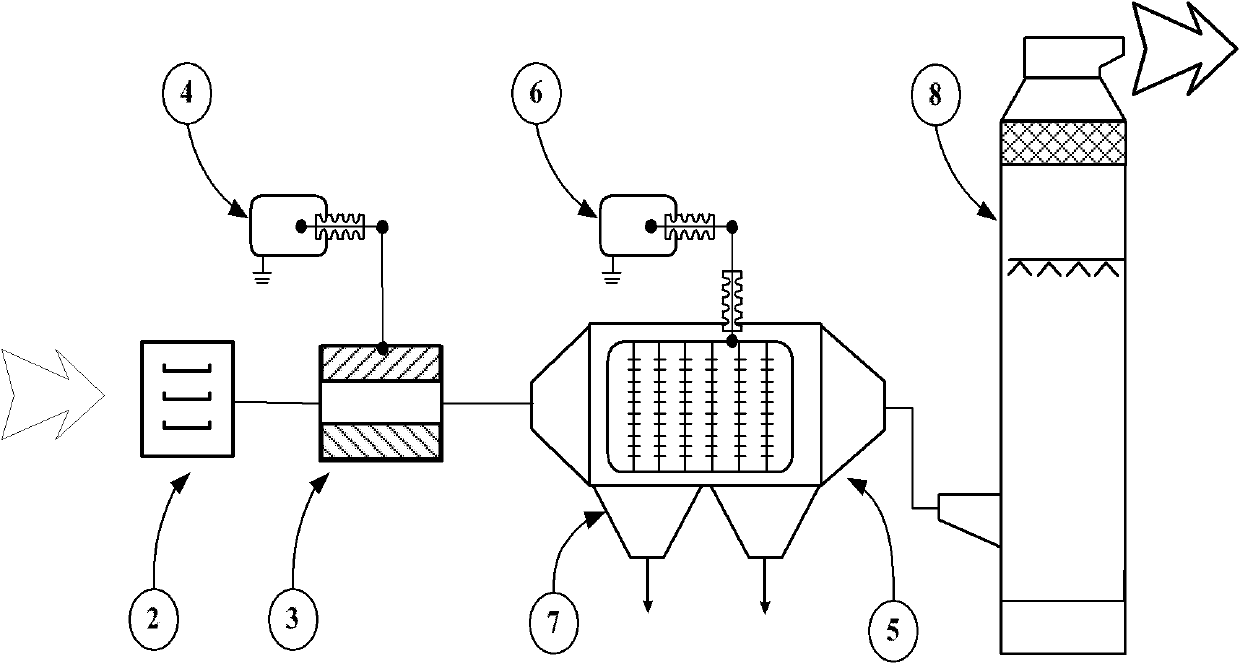

Coal-fired power plant smoke gas circulating adsorbent demercuration device and demercuration method

PendingCN106422666AQuality impactImprove mercury removal efficiencyCombination devicesGas treatmentSorbentMagnetic separator

The invention discloses a coal-fired power plant smoke gas circulating adsorbent demercuration device and a demercuration method, and belongs to the technical field of smoke gas purification. Circulating demercuration adsorbent magnetic active carbon is ejected into a flue behind an air pre-heater through a gas conveying device, the magnetic active carbon adsorbs mercury in the smoke gas, and then the magnetic active carbon and ash are trapped by an electric dust remover, are screened by a multi-stage magnetic separator and enter a conical separator to finish separation of the magnetic active carbon and magnetic substances in the ash, and the recycled magnetic active carbon enters an ejecting device again; and after circulation is conducted for a certain time, the magnetic active carbon enters an adsorbent regeneration device to desorb mercury, and the regenerated magnetic active carbon enters an adsorbent ejecting system to be recycled. By the method, on the basis that coal-fired power plant smoke gas purification equipment is not changed, the mercury removing efficiency is high, the adsorbent can be recycled, the cost is reduced, and the problems about the influence of the adsorbent on the fly ash quality and secondary release of the mercury are solved.

Owner:XIAN THERMAL POWER RES INST CO LTD +1

Method for removing total mercury from coal burning smoke

InactiveCN101850212ASimple methodEasy to operateDispersed particle separationGypsumEnvironmental chemistry

The invention discloses a method for removing total mercury from coal burning smoke, which comprises the following steps of: mixing a lime (limestone) desulfurizing agent and a sodium sulfide mercury remover uniformly, spraying the uniformly mixed solution into a desulfurizing tower during lime (limestone)-gypsum wet smoke desulfuration, and removing the total mercury from the smoke at the same time during the lime (limestone)-gypsum wet smoke desulfuration. The method is simple and convenient to operate, does not need great reformation on the conventional desulfuration facilities, has lower mercury removal cost, and does not produce secondary pollution to the environment.

Owner:SOUTH CHINA UNIV OF TECH

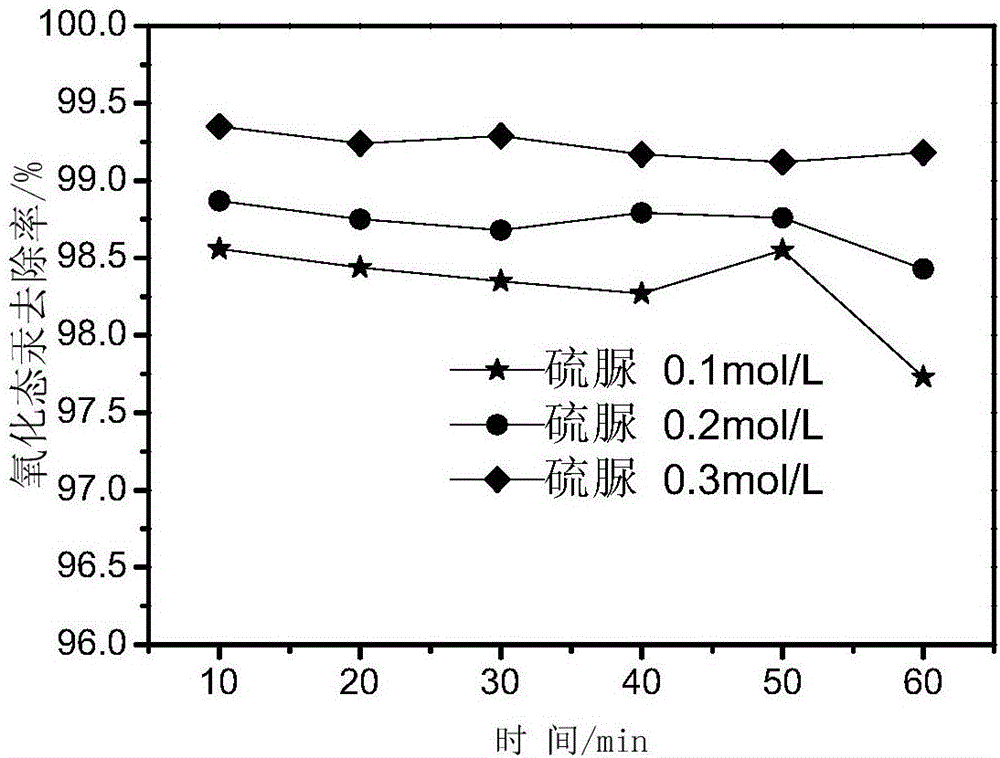

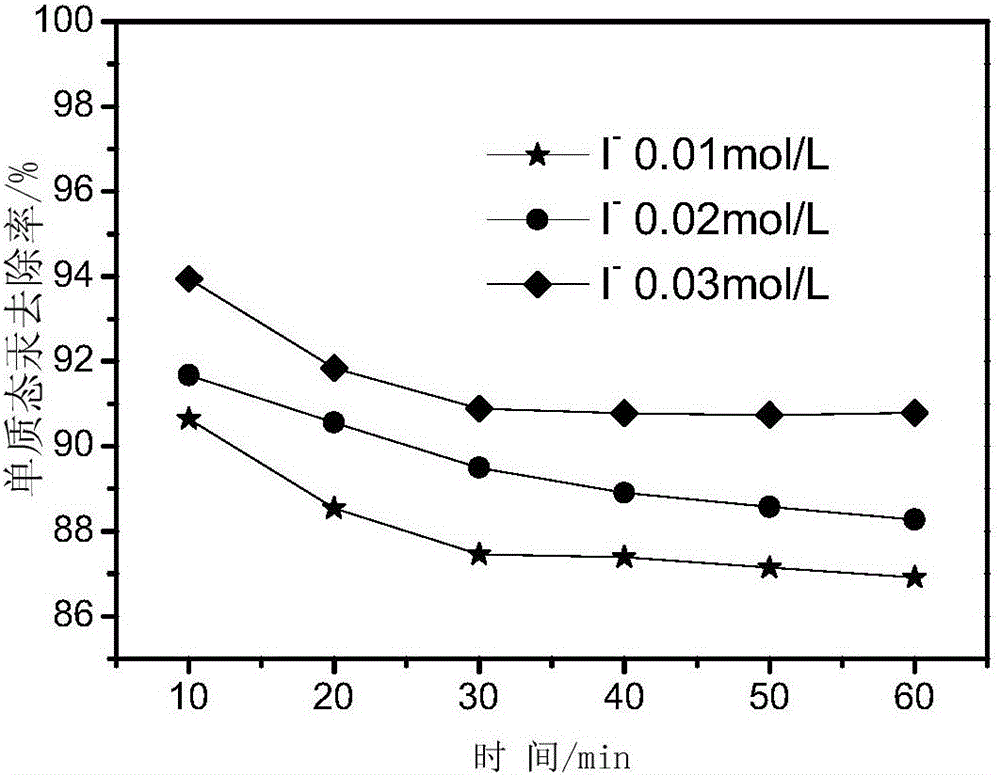

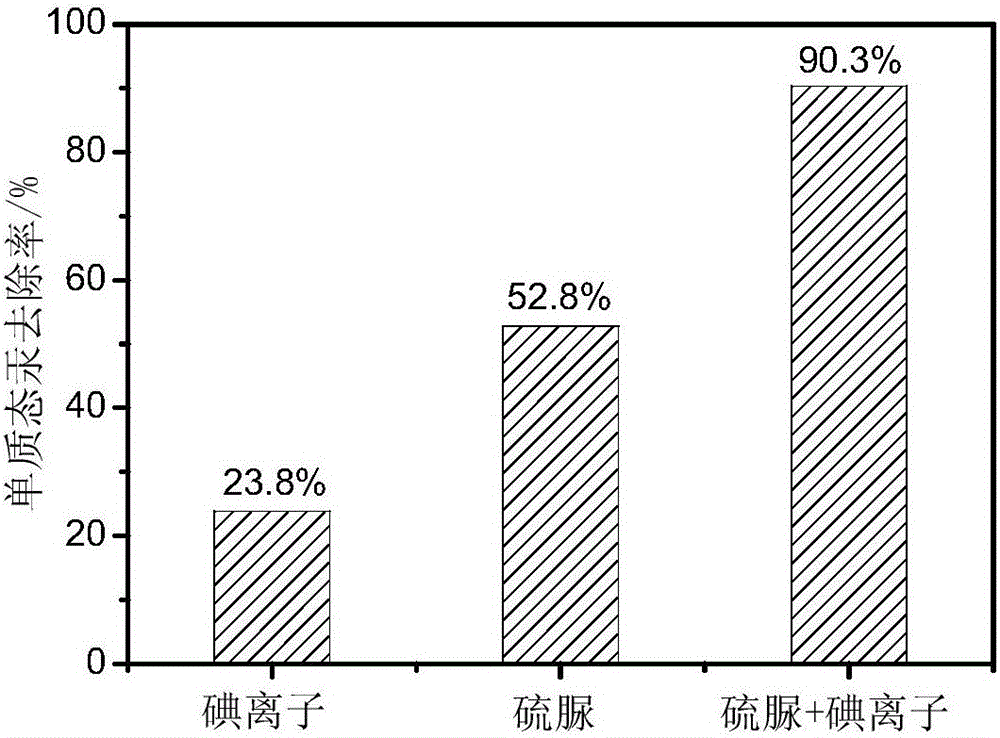

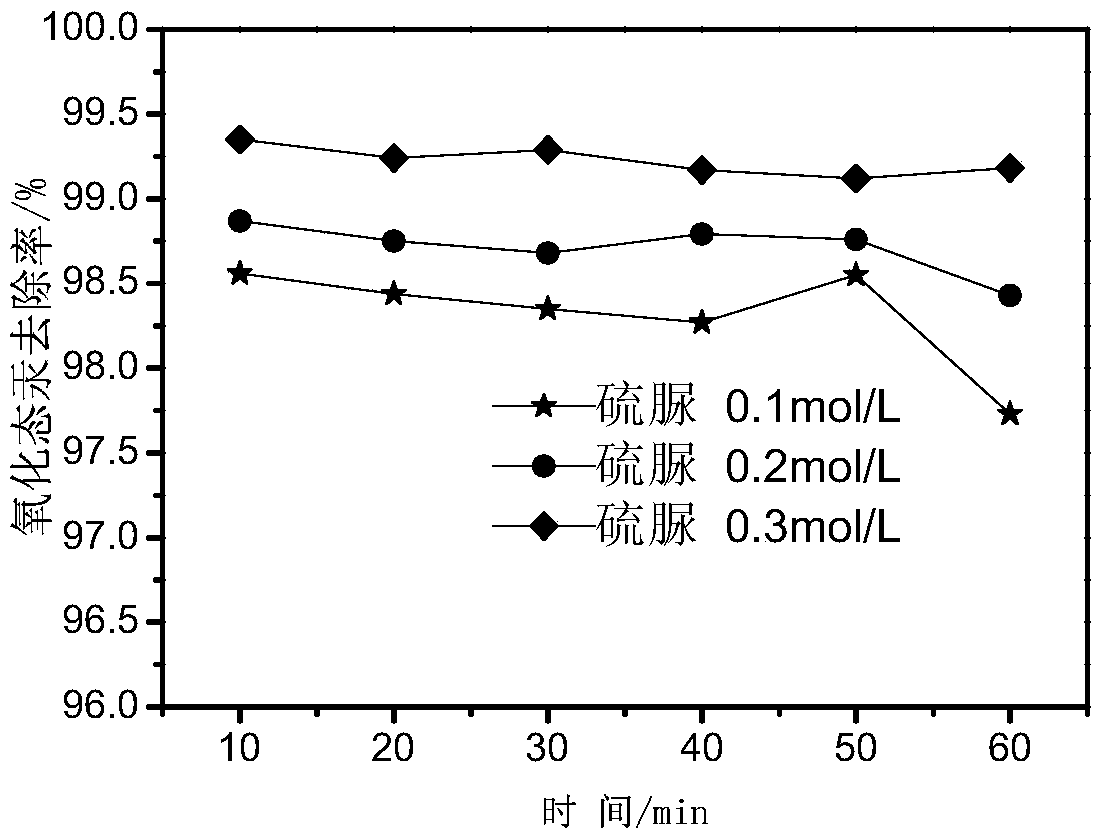

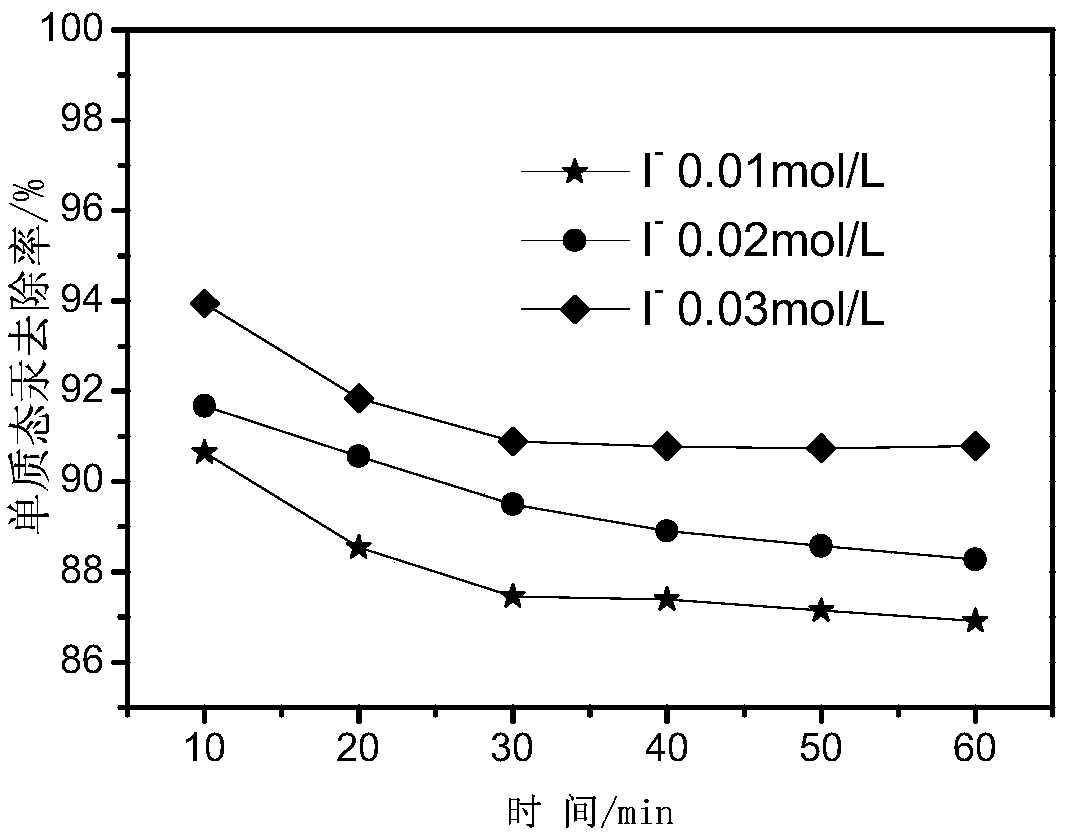

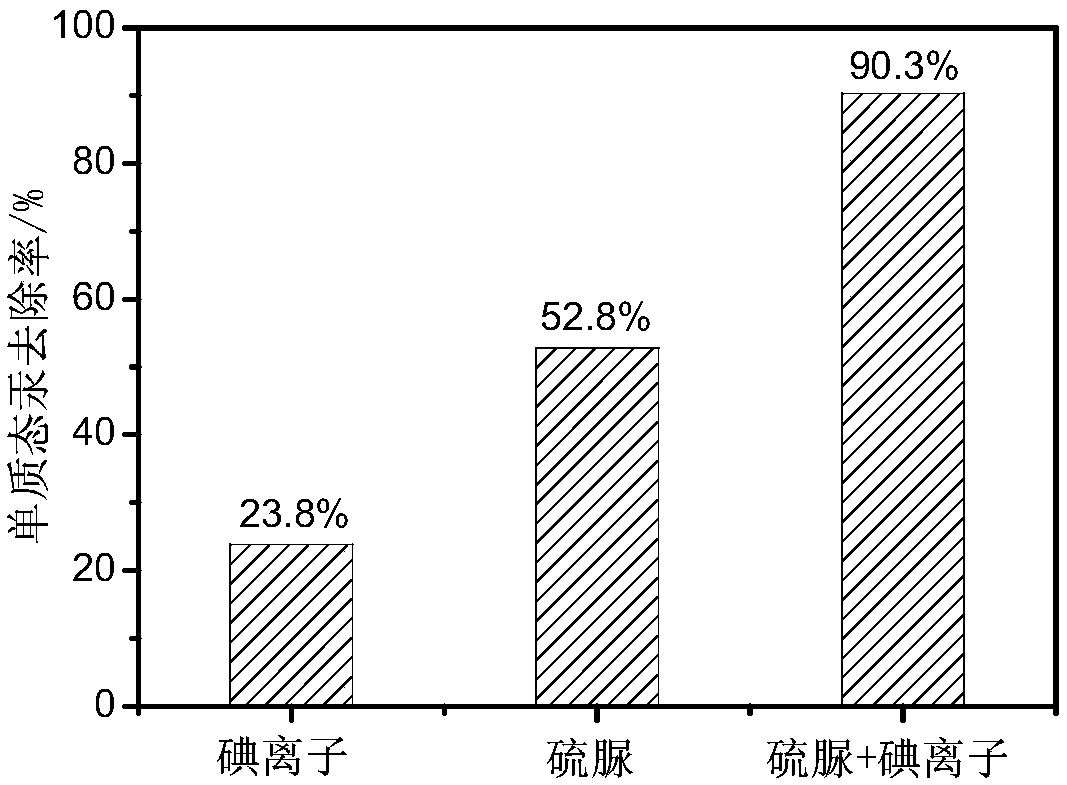

Absorption liquid for removing mercury from mercury fume and mercury removal method for mercury fume

ActiveCN106268258AEfficient removalEfficient oxidation removalDispersed particle separationSodium stearateThiourea

The invention discloses an absorption liquid for removing mercury from mercury fume and a mercury removal method for the mercury fume. The absorption liquid is prepared from components as follows: iodide ions, thiourea compounds, formamidine disulphide and sodium stearate, the mercury fume is contacted with the absorption liquid for a reaction, and elemental mercury and mercury in the oxidation state in the mercury fume enter the absorption liquid. Accordingly, elemental mercury and mercury in the oxidation state in the mercury fume are removed efficiently simultaneously, the absorption liquid is particularly applicable to processing of fume with high content of mercury, and the mercury removal efficiency is 90% or higher.

Owner:CENT SOUTH UNIV

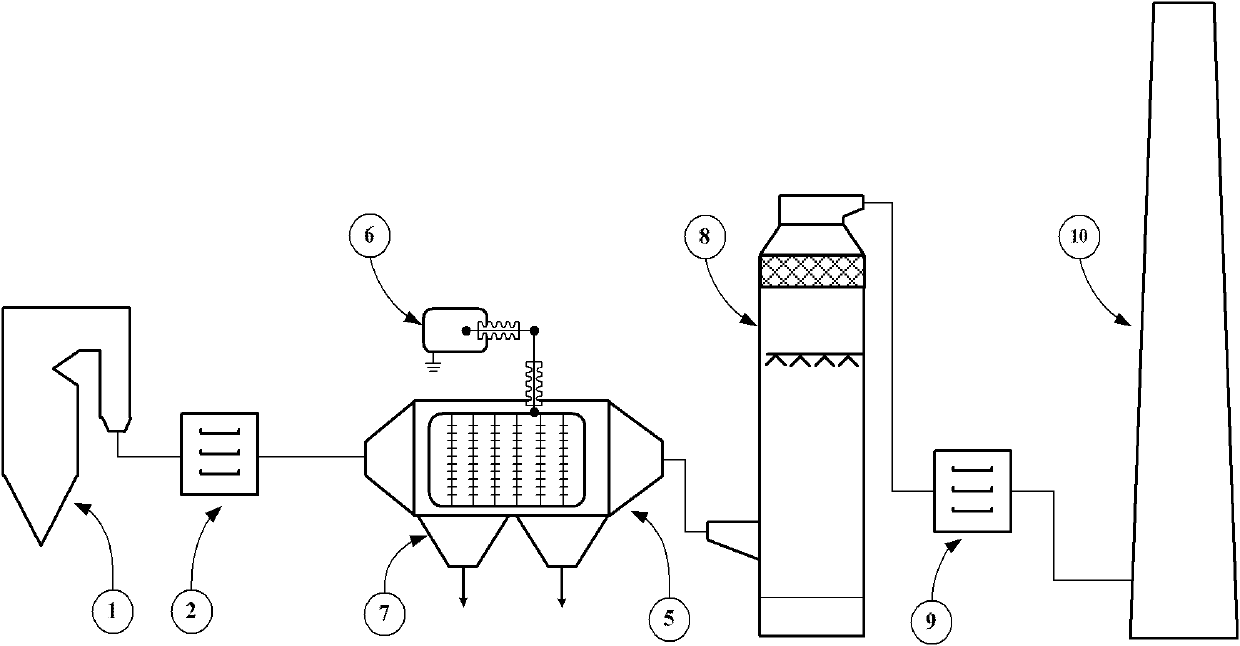

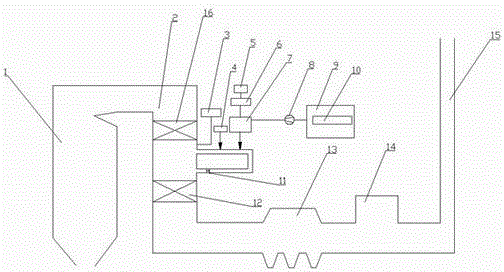

Flue gas demercuration device and method utilizing polyvinyl chloride and boiler fly ash

InactiveCN103423757AImprove removal effectImprove mercury removal efficiencyLighting and heating apparatusDispersed particle separationAir preheaterSorbent

The invention provides a flue gas demercuration device and method utilizing polyvinyl chloride and boiler fly ash. The flue gas demercuration device comprises a boiler furnace, a flue and a chimney, wherein the boiler furnace, the flue and the chimney are connected in sequence, and an economizer, an air preheater, an electrostatic dust collector and a wet desulphurization tower are arranged on the flue in sequence. The flue gas demercuration device further comprises a flue gas mercury on-line monitor, a circulation flue, a crushing device, a gasification device, an air heater, a feeding device and an intelligent control device, wherein the circulation flue is arranged on the flue between the economizer and the air preheater, a discharge port of the feeding device is connected to the circulation flue, and the feeding device comprises a polyvinyl chloride waste material feeding machine and an adsorbent feeding machine. According to the flue gas demercuration device and method utilizing the polyvinyl chloride and the boiler fly ash, hydrogen chloride generated by a polyvinyl chloride waste material is used for oxidizing zero-valent mercury into gaseous divalent mercury, and then the boiler fly ash is used for adsorbing flue gas mercury. On the premise that large-scale reconstruction is not conducted on an existing pollution control device, the flue gas demercuration device and method utilizing the polyvinyl chloride and the boiler fly ash can greatly improve the demercuration effect and demercuration efficiency, thereby lowering demercuration cost, and realizing environment-friendly utilization of the polyvinyl chloride waste material.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

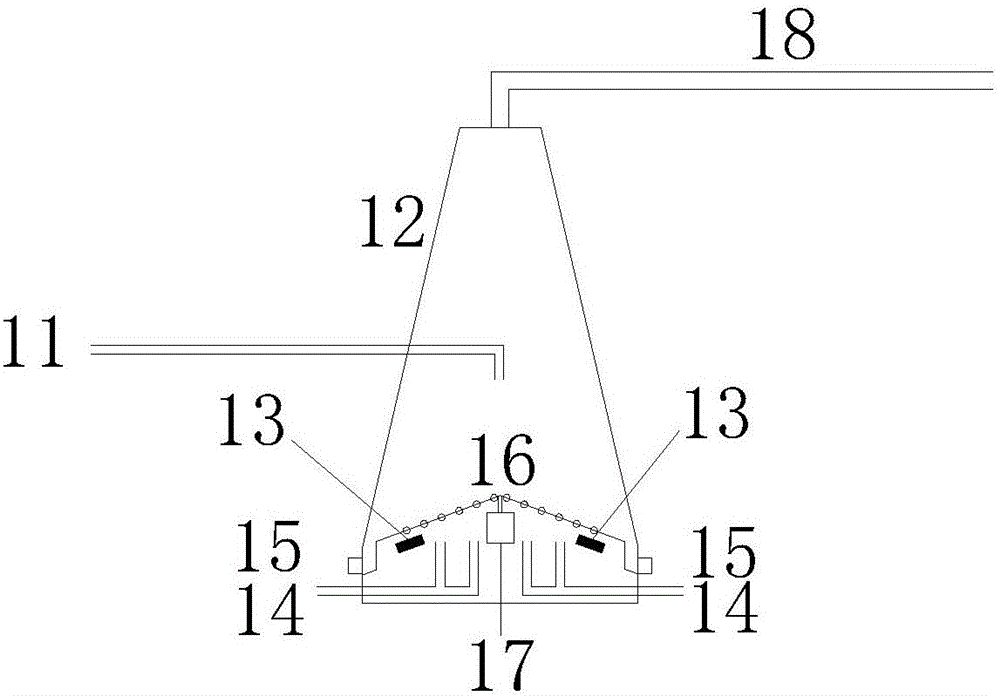

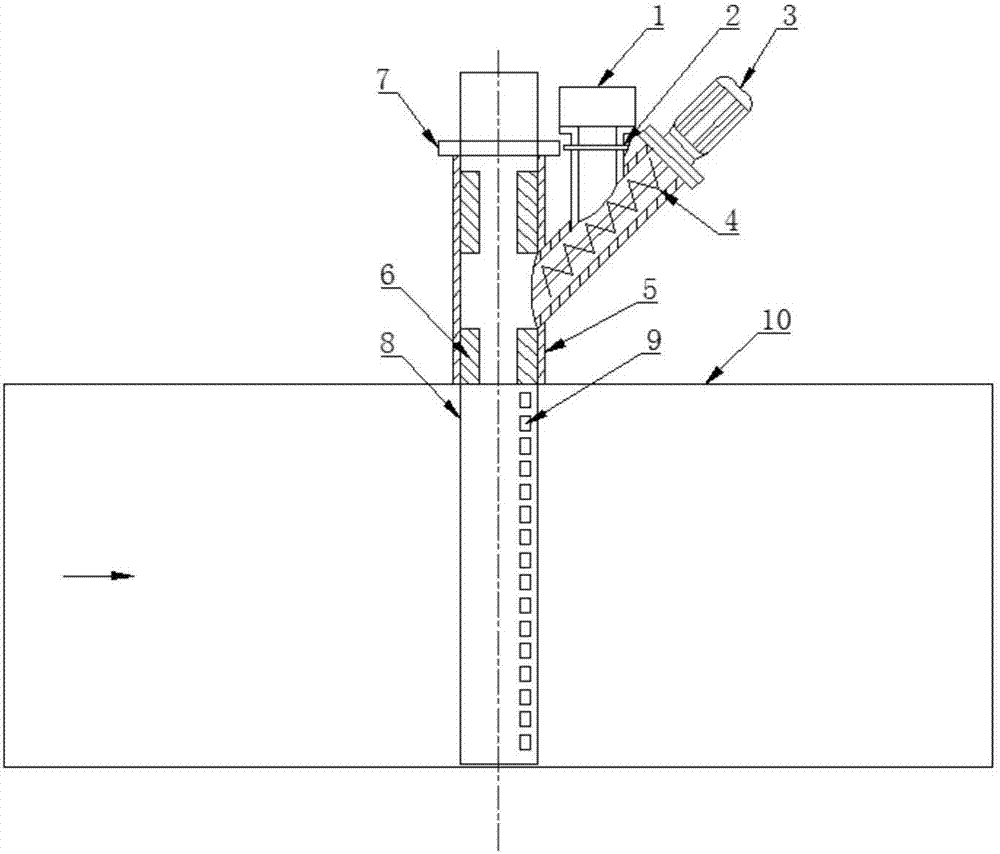

Efficient demercurating adsorbent spraying device

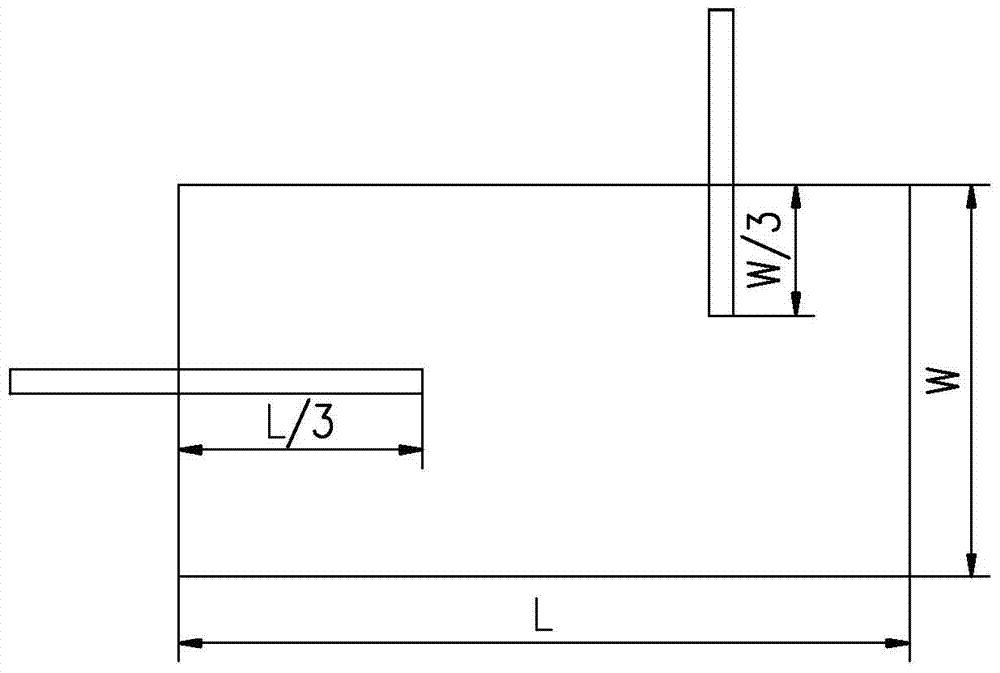

PendingCN107469570AIncrease disturbanceIncreased turbulence intensityGas treatmentLighting and heating apparatusFlueEngineering

The invention belongs to the related technical field of mercury control in coal-fired flue gas and discloses an efficient demercurating adsorbent spraying device which comprises a primary spray barrel and a cyclone, wherein an accommodating cavity is formed in the primary spray barrel, and two rows of nozzles which are arranged along two length directions of the primary spray barrel are formed in one end of a flue of the accommodating cavity, separately; the cyclone is accommodated in the accommodating cavity and is located out of the flue; air entering the accommodating cavity from one end, far from the flue, of the primary spray barrel separately forms straight flow air and spiral air through the cyclone, and the straight flow air and spiral air are used for driving an adsorbent entering the accommodating cavity to move spirally downward and the adsorbent is sprayed out from the nozzles to be mixed with flue gas for demercuration. The adsorbent spraying direction is not a single flue gas flowing direction, so that disturbance of the adsorbent is enhanced, the turbulence intensity is enhanced, the demercurating efficiency is increased, and the device is simple in structure and quiet during working.

Owner:HUAZHONG UNIV OF SCI & TECH

Coal-fired flue gas heavy metal pollutant removal device

InactiveCN109999653AFully contactedHigh catalytic efficiencyGas treatmentDispersed particle separationFlue gasEngineering

The invention discloses a coal-fired flue gas heavy metal pollutant removal device. The device comprises multiple grilles, transparent glass, a first pipeline and a second pipeline. The multiple grilles are evenly spaced along the height direction of a chimney inside the chimney. The transparent glass is arranged to match the grilles. The transparent glass is arranged on the chimney wall above thecorresponding grilles. An inlet end of the first pipeline is connected with an outlet end of an induced draught fan, and an outlet end of the first pipeline is connected with the bottom of the chimney. An inlet end of the second pipeline is connected with an electrostatic precipitator, and an outlet end of the second pipeline is connected with an inlet end of the induced draught fan. The invention has the following beneficial effects: through full contact between visible light and the surface of a photocatalyst, catalytic efficiency is effectively enhanced; by using visible light for mercuryremoval, the mercury removal cost is reduced; and according to actual situations, an ultraviolet source is additionally arranged to further enhance the mercury removal efficiency.

Owner:DATANG ENVIRONMENT IND GRP

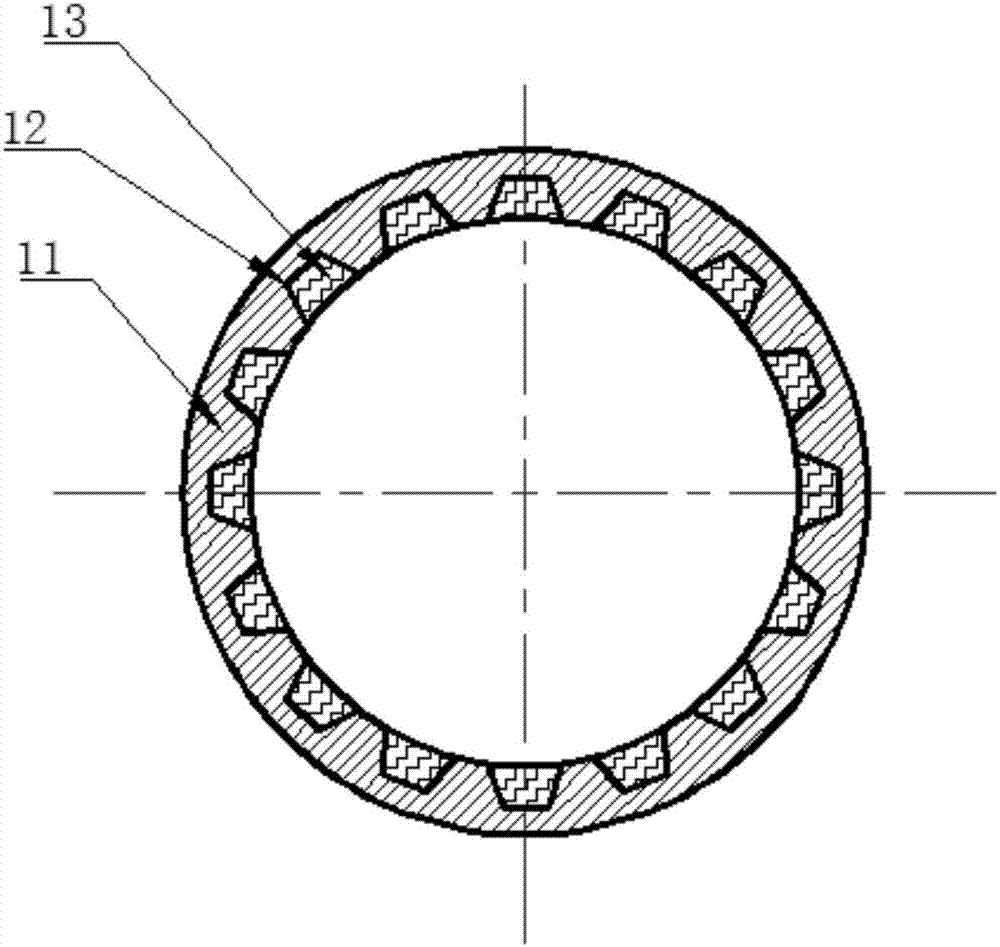

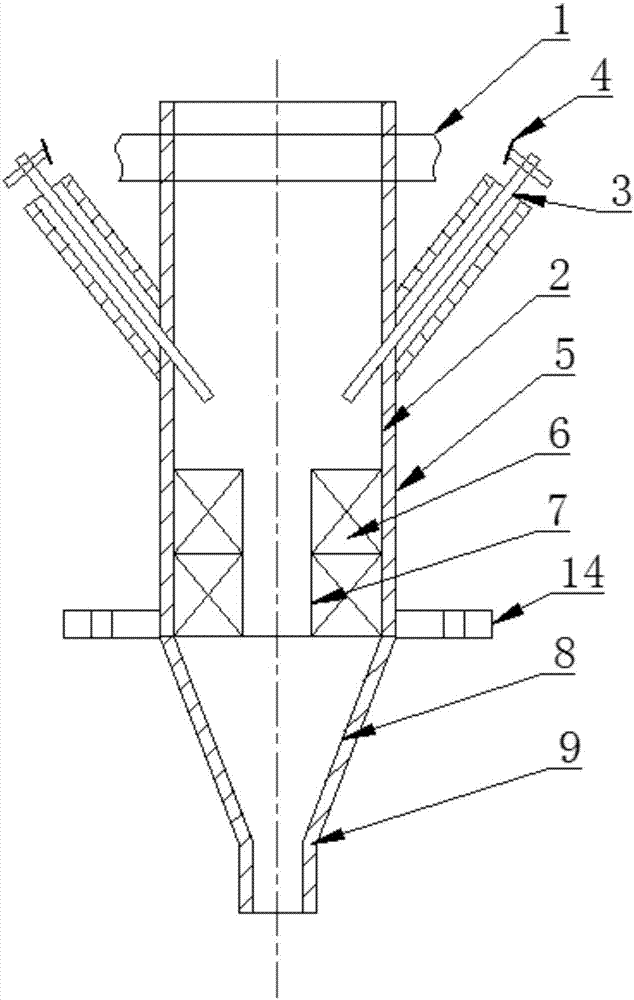

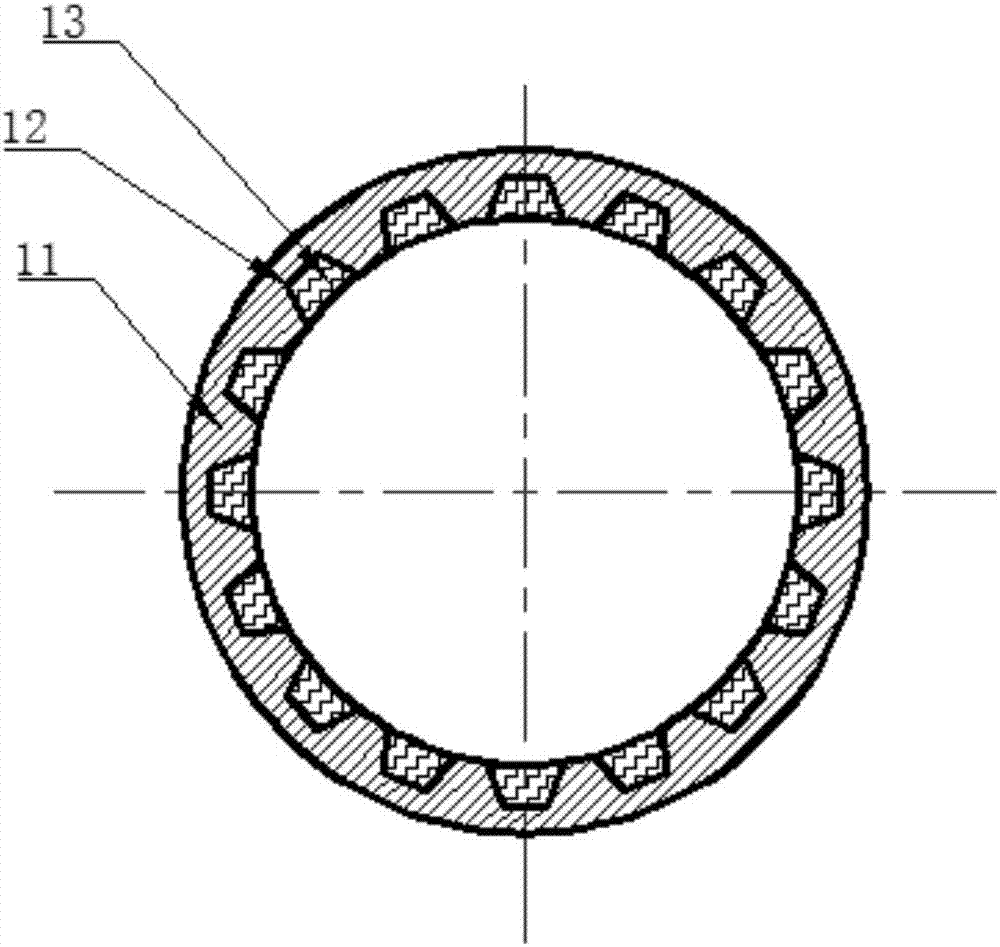

Rotational flow mercury adsorbent injection device

ActiveCN107486351AHigh speedFacilitated DiffusionGas treatmentDispersed particle separationSorbentEngineering

The invention belongs to the relevant technical field of mercury control in coal-fired flue gas, and discloses a rotational flow mercury adsorbent injection device. The device comprises a main injection barrel and two rotational flow impellers. The main injection barrel comprises a straight line section, a nozzle and a contraction section for connecting the straight line section with the nozzle. The contraction section is in a conical shape, the opening diameter of the end, connected with the straight line section, of the contraction section is larger than the opening diameter of the end, connected with the nozzle, of the contraction section, the two rotational flow impellers are stacked to the straight line section, air entering the straight line section form direct flow air and rotational flow air after passing through the rotational flow impellers, the direct flow air and the rotational flow air are mixed to drive a mercury adsorbent entering the containing cavity to enter the contraction section and accelerated through the contraction section and then enter the nozzle, and the nozzle is used for injecting the mercury adsorbent into a flue to be mixed with smoke gas in the flue for mercury adsorption and removal. The mixed gas is accelerated through the contraction section, the contact probability of the mercury adsorbent and smoke gas is increased, and the mercury adsorption efficiency is improved.

Owner:HUAZHONG UNIV OF SCI & TECH

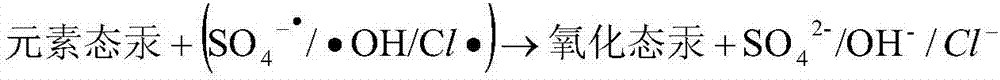

A method for removing elemental mercury in coal-fired flue gas

InactiveCN105233687BReduce the cost of mercury removalAchieve conversionDispersed particle separationHydrogen SulfateRubidium

A method for removing elemental mercury in coal-burning flue gas. The removal is carried out in a spray absorption tower. The prepared absorbent is sprayed down from the upper part of the spray absorption tower, and the mercury introduced from the lower part of the spray absorption tower is sprayed. The coal-fired flue gas is sprayed to fully react the elemental mercury in the coal-fired flue gas with the absorbent to realize the conversion of elemental mercury to divalent mercury; the absorbent includes oxidizing additives and magnetic catalysts, oxidizing The mass ratio of the additive to the magnetic catalyst is 2 to 5:1, and the oxidizing additive is one or more combinations of potassium hydrogen persulfate, sodium persulfate, sodium perborate, and sodium percarbonate, and the catalyst It is one or more mixtures of bismuth ferrite, cobalt doped bismuth ferrite, cobalt / lanthanum doped bismuth ferrite, cobalt / strontium doped bismuth ferrite, cobalt / rubidium doped bismuth ferrite. The invention has the characteristics of high utilization rate of the absorbent, repeated use of the catalyst, no secondary pollution, simple and convenient operation, stable operation, easy handling of the product, and convenient popularization and application.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

Modified carbon-based adsorbent as well as preparation method and application thereof

ActiveCN113713769AReduce usageLarge adsorption capacityGas treatmentOther chemical processesCupric bromideModified carbon

The invention discloses a modified carbon-based adsorbent as well as a preparation method and application thereof. According to the method, activated carbon is used as a carrier, cuprous chloride, copper chloride, ferric chloride, calcium chloride, copper bromide, ferrous bromide, calcium bromide, cuprous iodide, ferrous iodide, calcium iodide and the like are loaded as activators, and a modified carbon-based material is successfully prepared through normal-temperature mechanical ball milling activation and used as an adsorbent for fixed removal of mercury in flue gas. The method is simple in process, easy to operate and short in consumed time; operation can be carried out at normal temperature without high-temperature roasting, and energy consumption is low; no wastewater or waste residue is generated in a modification process, the consumption of water and raw materials is small, and cost is remarkably reduced; and the modified carbon-based adsorbent is large in mercury adsorption capacity and high in adsorption rate, and a product obtained after mercury removal is environmentally friendly and free of secondary pollution.

Owner:CENT SOUTH UNIV

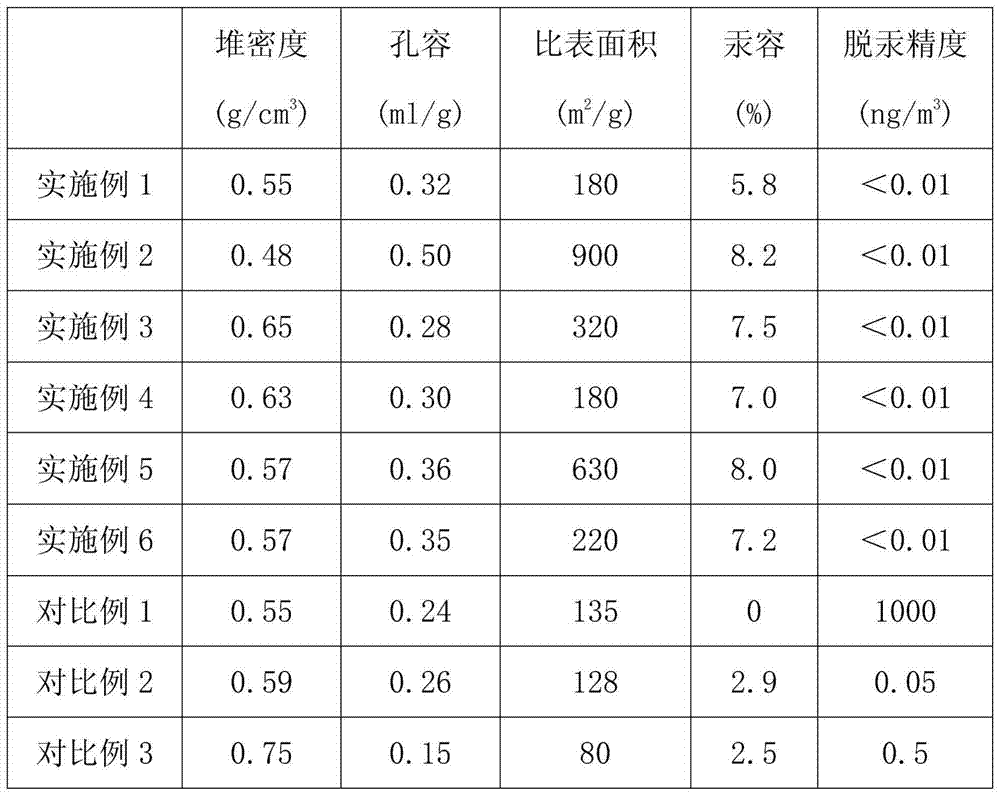

A kind of preparation method of copper sulfide mercury removal agent

ActiveCN105498469BReduce usageGood mercury removal effectGas treatmentDispersed particle separationActive componentGranularity

The invention provides a preparation method of a copper sulphide mercury removal agent. the preparation method comprises the following steps: mixing copper sulphide powder, a powdery carrier and an inorganic binder to form a mixture; spraying an organic binder aqueous solution into the mixture and rolling to form a ball; and drying the ball. By using copper sulphide with specific grain size and granularity as a raw material, on one hand, use of a vulcanizing agent is avoided so as to thoroughly solve problems of high toxicity, unbearable smell and residual vulcanizing agent existing in the preparation process of the copper sulphide mercury removal agent; and on the other hand, it is beneficial to increase active sites so as to make the mercury removal agent show excellent mercury removal activity. By the rolling mode, the active component is uniformly dispersed onto the surface of the carrier, and it is ensured that the mercury removal agent has a proper porous structure and as large specific surface area as possible. Thus, it helps raise mercury removal precision and mercury volume of the mercury removal agent and reduce bulk density of the mercury removal agent, and service life of the mercury removal agent is prolonged. Mercury removal cost is then reduced greatly.

Owner:BEIJING SJ ENVIRONMENTAL PROTECTION & NEW MATERIAL CO LTD

Flue gas mercury removal device

InactiveCN101844024BImprove adsorption capacityGood adsorption effect for mercury removalDispersed particle separationFlue gasOperational maintenance

Owner:CHONGQING UNIV

Modified akadama soil adsorbent and preparation method thereof

InactiveCN106582586ALarge specific surface areaImprove mercury removal efficiencyGas treatmentOther chemical processesFlue gasSorbent

The invention discloses a modified akadama soil adsorbent and a preparation method thereof. The modified akadama soil adsorbent is prepared from the following raw materials in parts by weight: 34 to 42 parts of akadama soil, 2 to 6 parts of a levelling agent OP, 5 to 13 parts of tannic acid and 13 to 21 parts of propylene glycol. The adsorbent is obtained by mixing and grinding the akadama soil and the levelling agent OP, then, adding propylene glycol solution, sealing and performing heating stirring treatment, heating and adding the tannic acid dropwise, cooling, performing ultrasonic treatment, stirring until a product is dry, and performing high-temperature sintering. According to the adsorbent which is prepared by mixing and grinding the akadama soil and the levelling agent OP and treating through the propylene glycol and the tannic acid, the specific surface area is prompted to be improved; when the adsorbent is applied to mercury treatment of flue gas, the mercury removal efficiency is greatly improved and reaches over 95 percent. According to the modified akadama soil adsorbent and the preparation method thereof, the process is simple, the process flow is short, the cost is low, wide-range popularization and use are facilitated, the adsorbent can be reutilized, and the mercury removal cost can be greatly reduced.

Owner:HENAN TIMECLOUD COMM TECH CO LTD

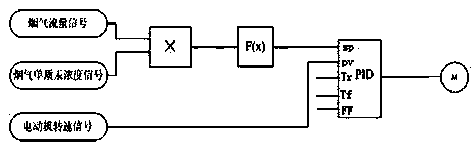

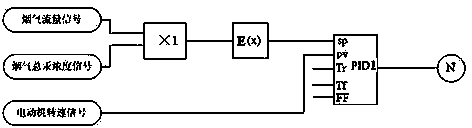

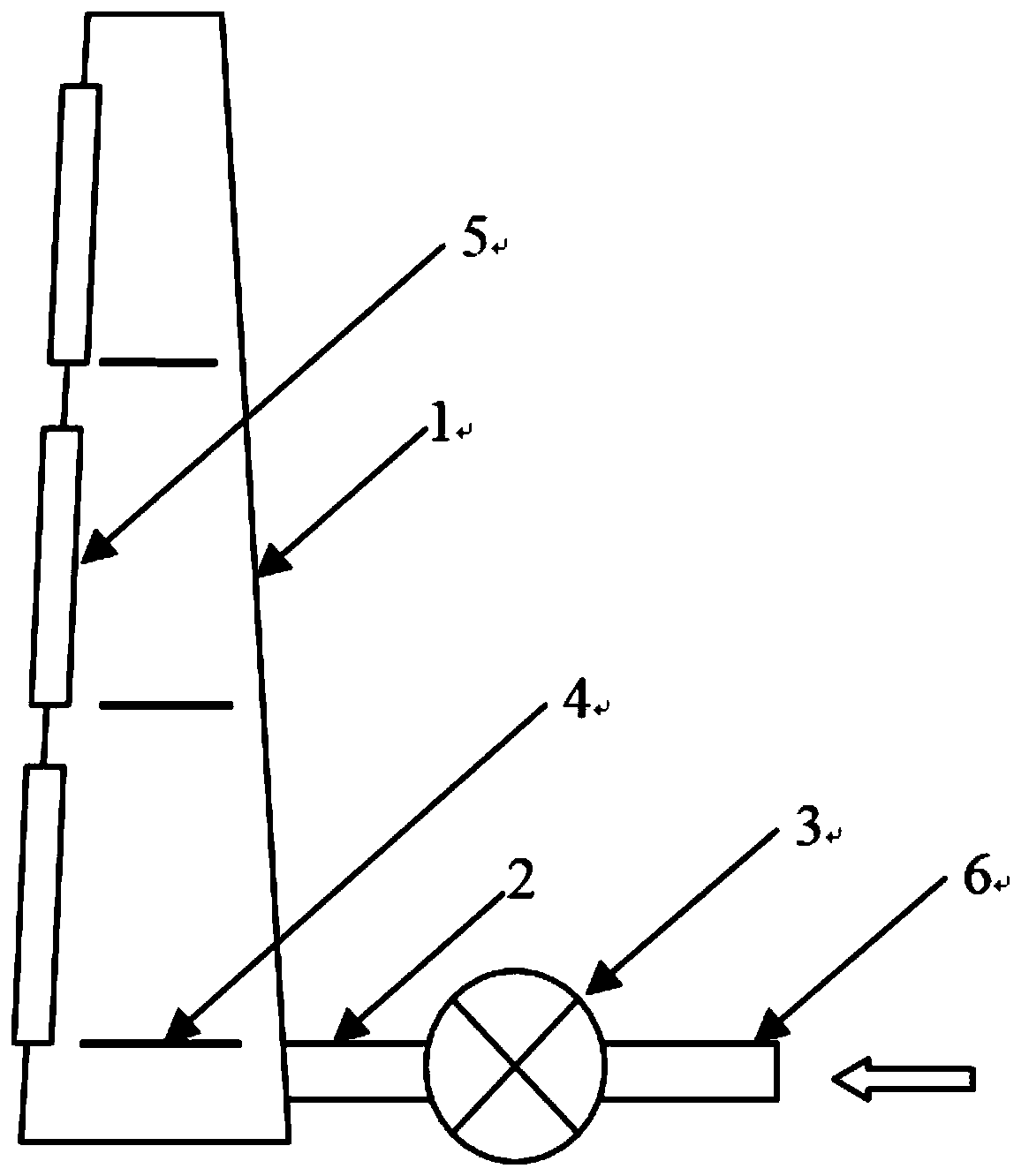

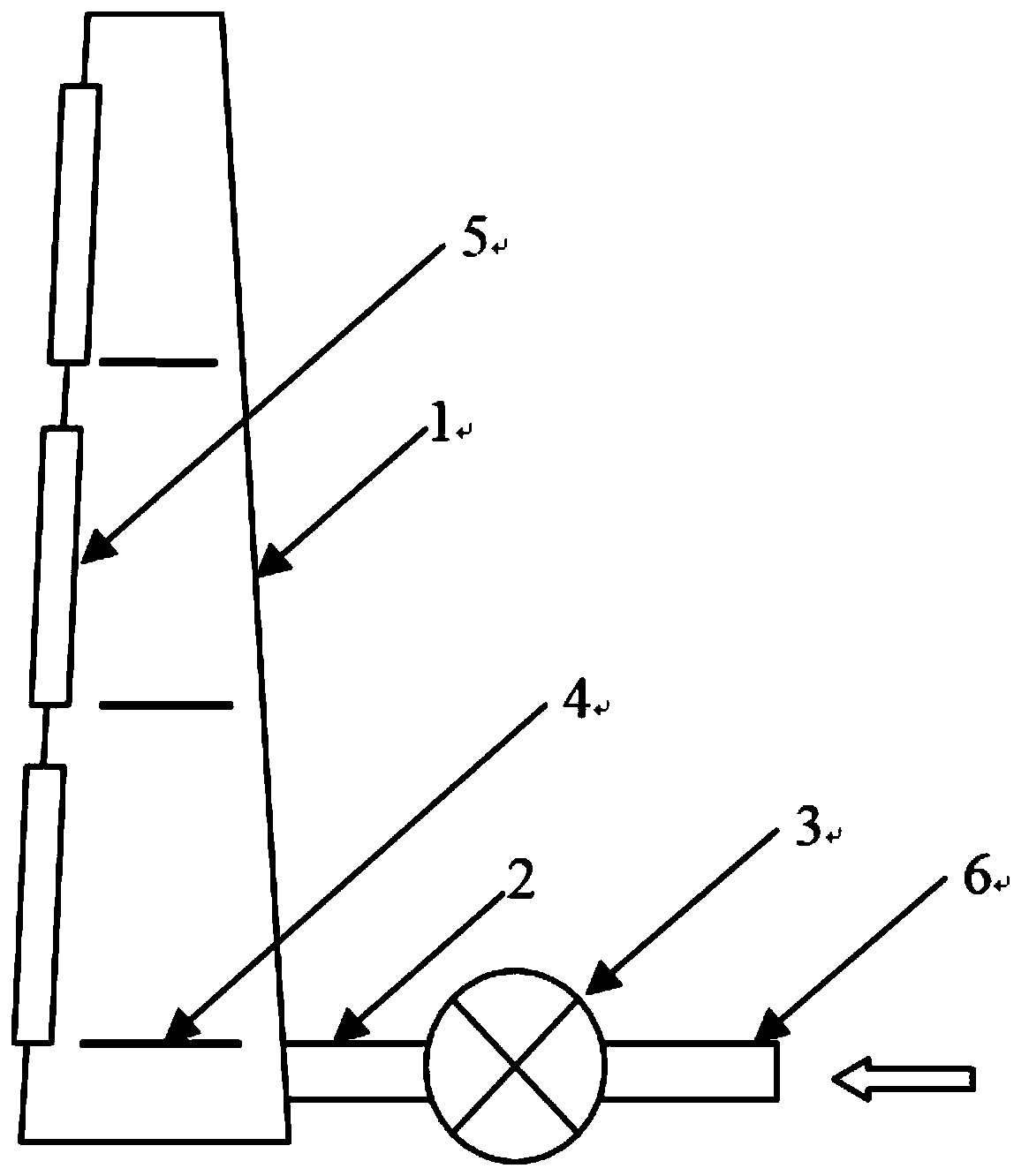

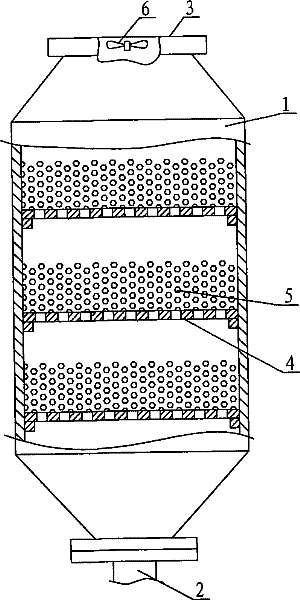

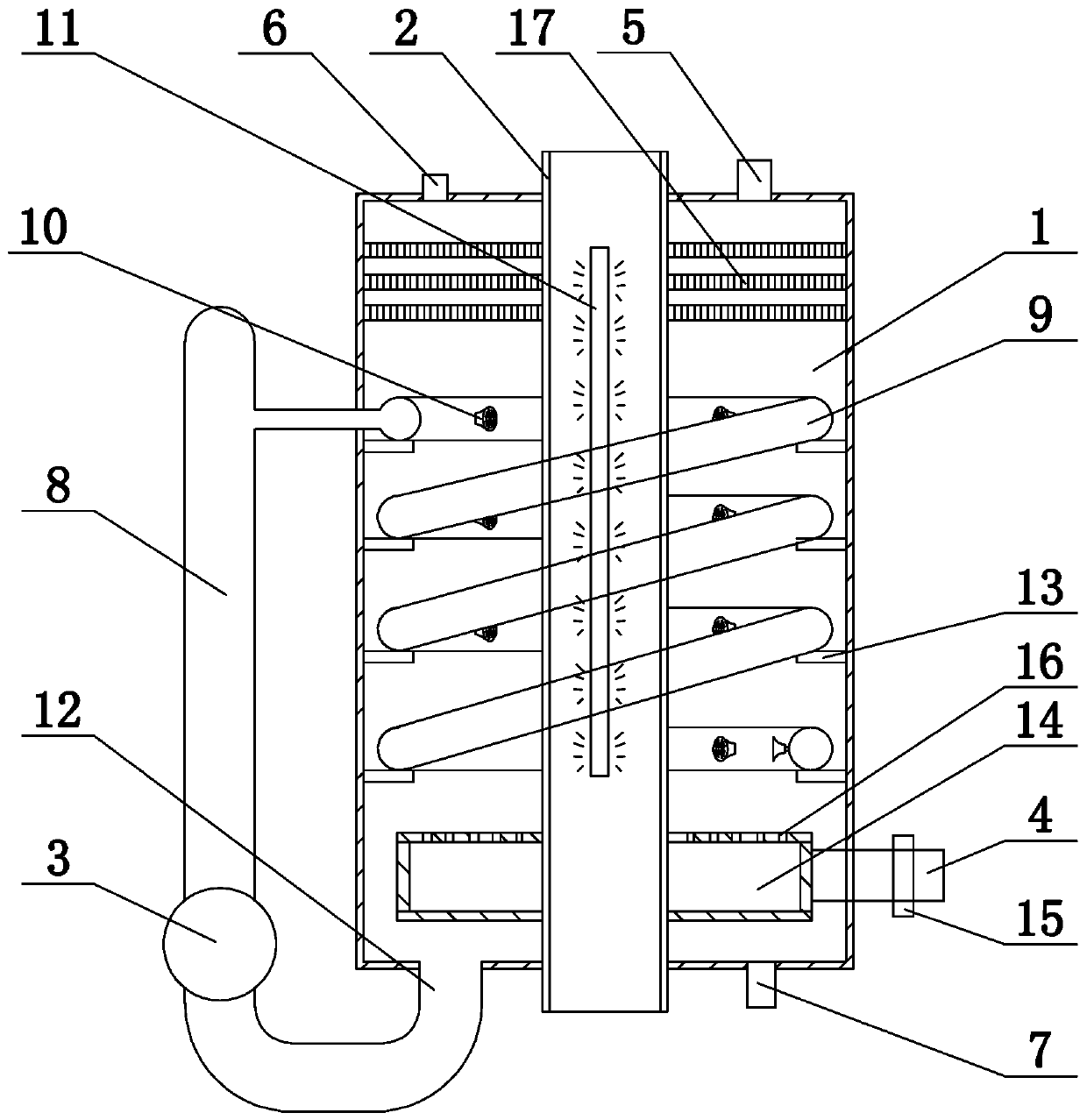

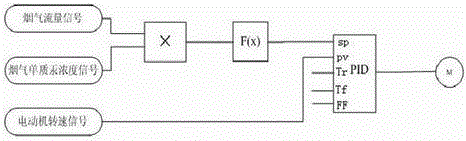

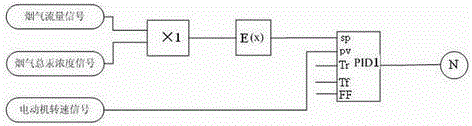

An integrated method of adsorbent activation and spray mercury removal

ActiveCN106178831BReduce dosageImprove utilization efficiencyGas treatmentDispersed particle separationSorbentFlue gas

The invention discloses an integrated adsorbent activation and spraying demercuration method which comprises the following steps: monitoring the mercury concentration of flue gas in real time by virtue of an online mercury concentration monitor (6), and dynamically regulating a second regulating valve (10) to control the injected volume and injection rate of a mercury adsorbent; dynamically regulating a third regulating valve (14) to control the injected volume and injection rate of compressed air; meanwhile, dynamically regulating a first regulating valve (7) on an online activation mechanism to control the injected volume and injection rate of an active component precursor; activating the adsorbent on line; spraying and injecting the activated adsorbent into a flue through a spraying mechanism, thereby implementing demercuration of the flue gas. According to the method, the demercuration performance of the adsorbent is optimized, active component waste is also avoided, the using amount of the adsorbent is reduced, and the demercuration cost is greatly reduced; in addition, the mercury adsorbent is activated on line in real time, and the method is adapted to frequent fluctuation of the mercury concentration.

Owner:HUAZHONG UNIV OF SCI & TECH

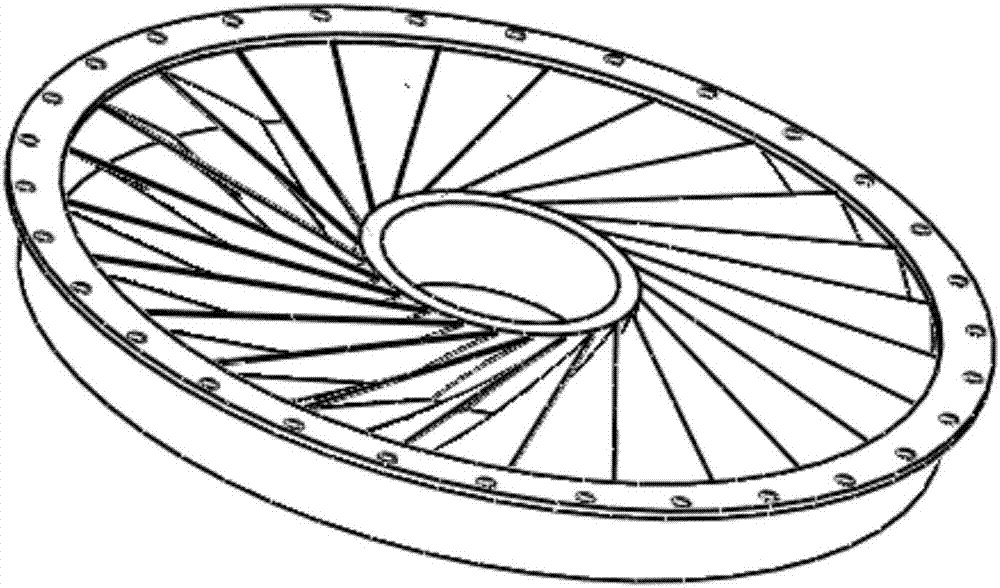

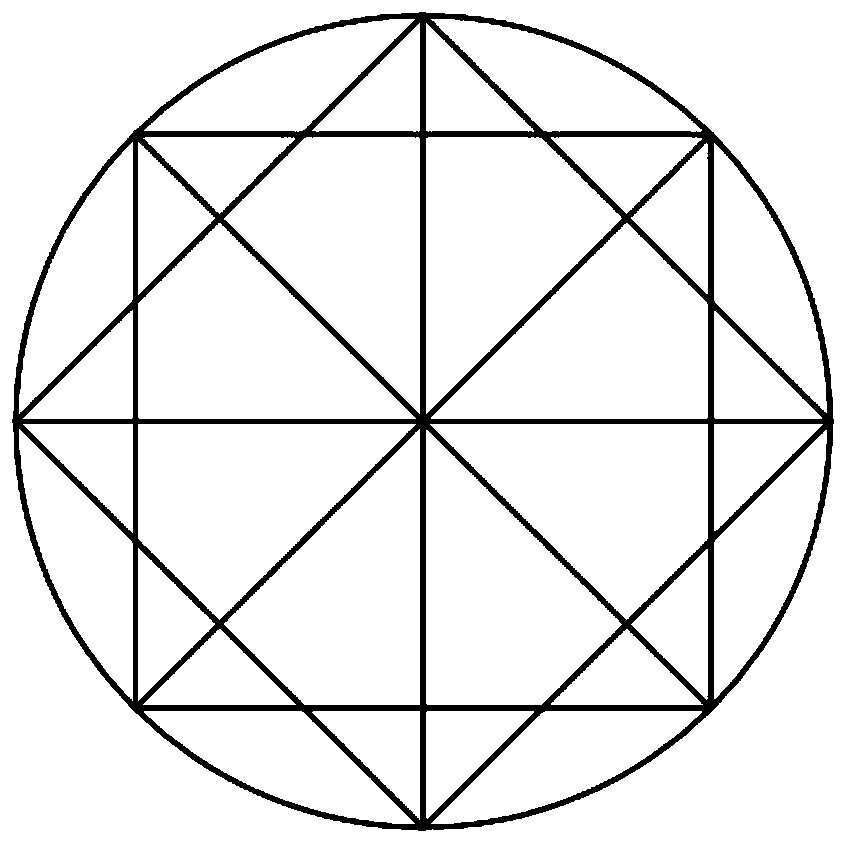

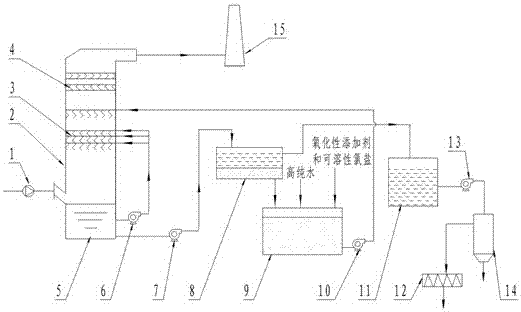

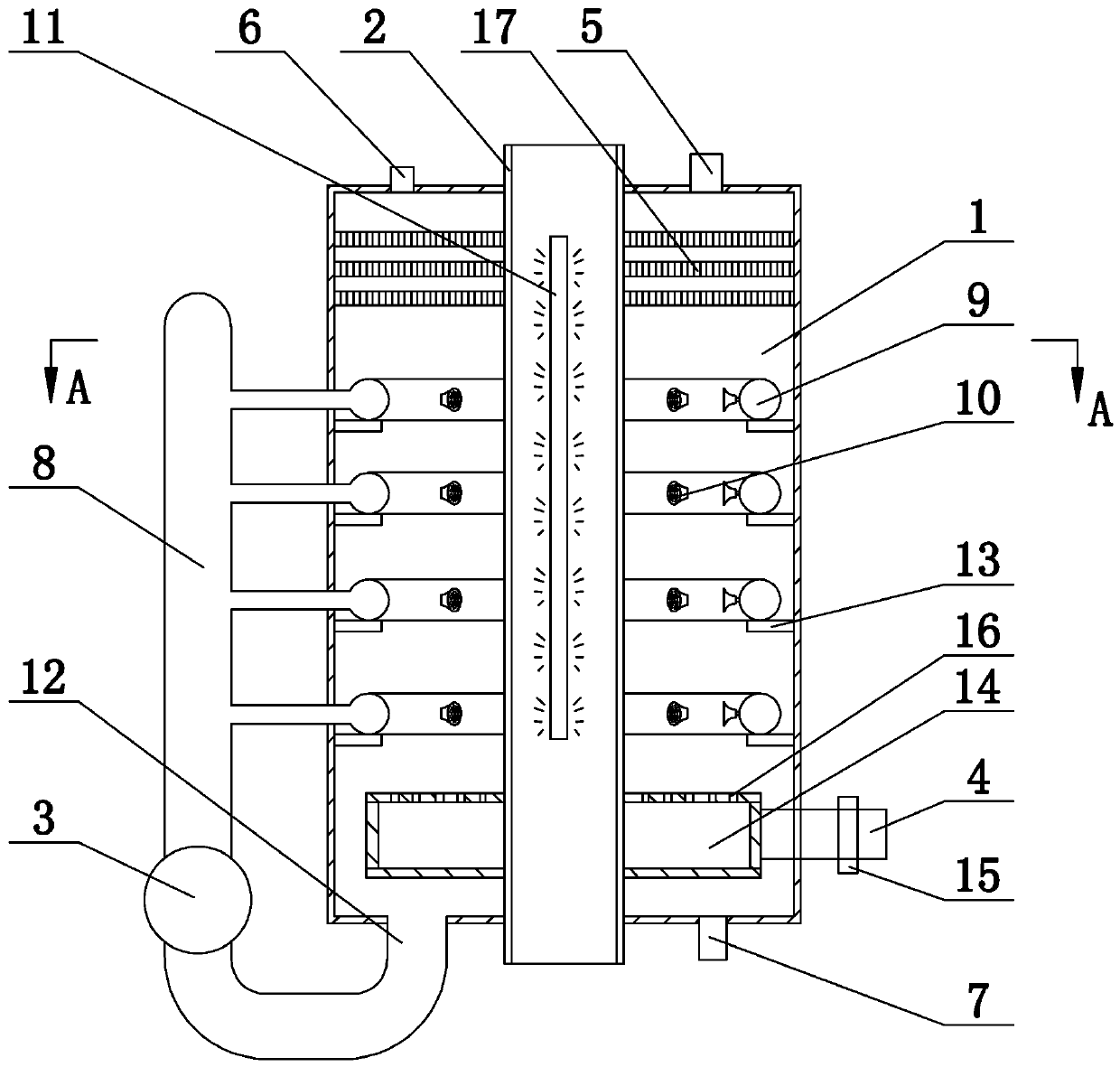

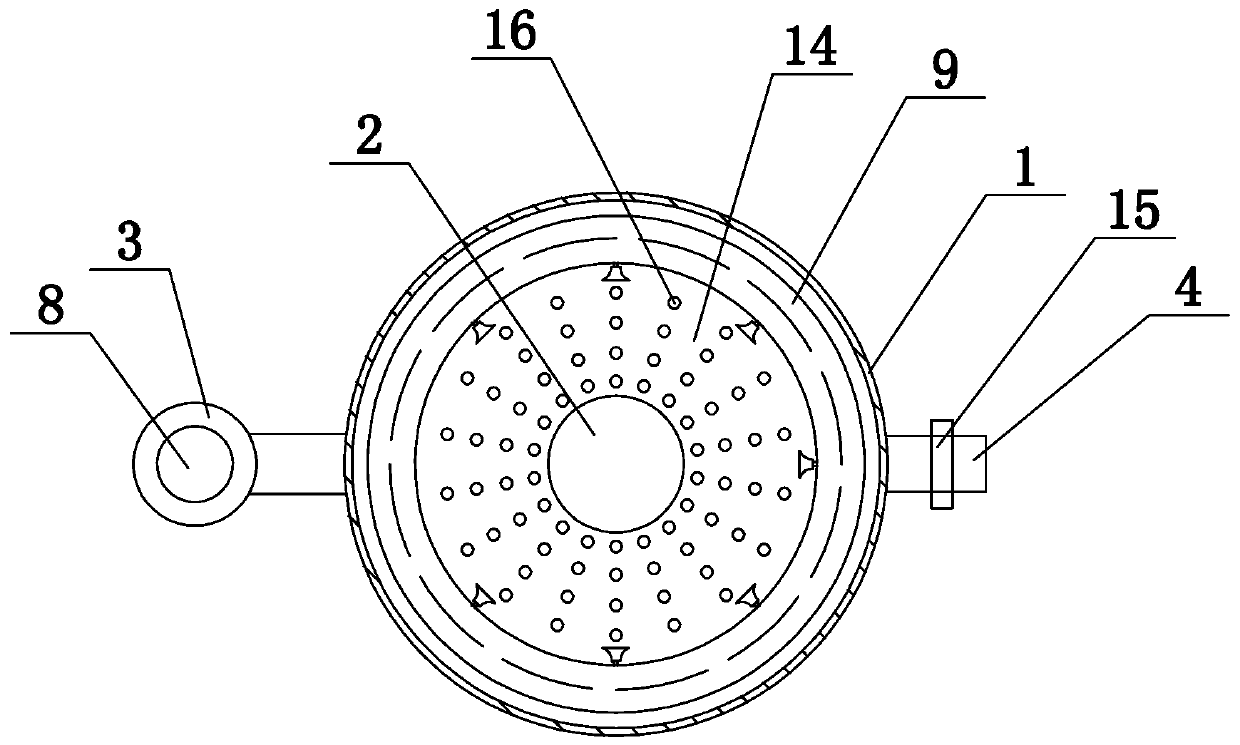

Flue gas mercury removal method based on visible light and its ring spray mercury removal device

ActiveCN105727742BTo achieve the purpose of mercury removalHas strong oxidizing propertiesGas treatmentPhysical/chemical process catalystsFlue gasHydroxyl radical

The invention provides a visible light-based flue gas mercury removal method and a circular spraying-type mercury removal device employing the same. A reaction liquid containing a compound catalyst Ag / AgBr<1-x>I<x>-BiOBr<1-x>I<x> (x=0.6-1) is irradiated by a visible light and then releases hydroxyl radical.OH, superoxide anion radical.O2<-> and holes h<+>; the hydroxyl radical .OH, the superoxide anion radical .O2<-> and the holes h<+> have high oxidizing property; Hg<0> in the flue gas can be oxidized into Hg<2+>, so that the Hg<0> is removed in a form of the Hg<2+>, and the target of flue gas mercury removal is achieved. The mercury removal device is a circular spraying-type mercury removal device; the mercury flue gas enters from the lower part of a reactor and flows from bottom to top; a visible light source is arranged in a central quartz glass tube at the middle part of the reactor; circular spraying pipes are circularly arranged employing the central quartz glass tube as the center; the reaction liquid is sprayed towards the central quartz glass tube from the circular spraying pipes, namely the reaction liquid is sprayed from the outside to the inside; and the flue gas from which mercury is removed is discharged from a gas outlet in the top end of the reactor.

Owner:HENAN POLYTECHNIC UNIV

Flue gas demercuration adsorbent

InactiveCN101856607BImprove adsorption capacityGood adsorption effect for mercury removalOther chemical processesSolid waste disposalFlue gasAdditive ingredient

The invention discloses a flue gas demercuration adsorbent. The adsorbent is characterized in that a method for preparing the flue gas demercuration adsorbent comprises the following steps of: mixing 10 to 25 weight percent of clay, 2 to 5 weight percent of polyethylene, 2 to 5 weight percent of rice hull, 5 to 10 weight percent of calcium oxide and the balance of pulverized fuel ash; adding water into the mixture for uniformly mixing; extruding, pelletizing and molding the mixture into particles of which the particle size is between 30 and 50 millimeters; and sintering the particles at the temperature of between 900 and 1,100 DEG C for 2 to 4 hours to obtain the flue gas demercuration adsorbent. The invention discloses the novel flue gas demercuration adsorbent. Since the pulverized fuelash is taken as a main raw material, other ingredients are only simple and conventional raw materials and a preparation method of the adsorbent is a conventional pelletizing or sintering method and the like, and the manufacturing cost of the adsorbent is lower than that of conventional adsorbents. Therefore, demercuration cost can be greatly lowered in a demercuration process.

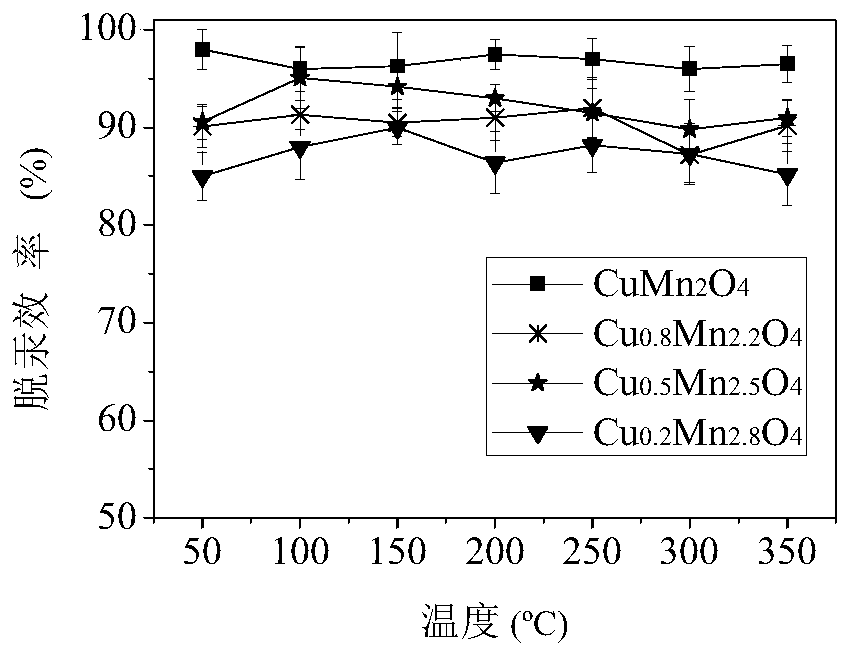

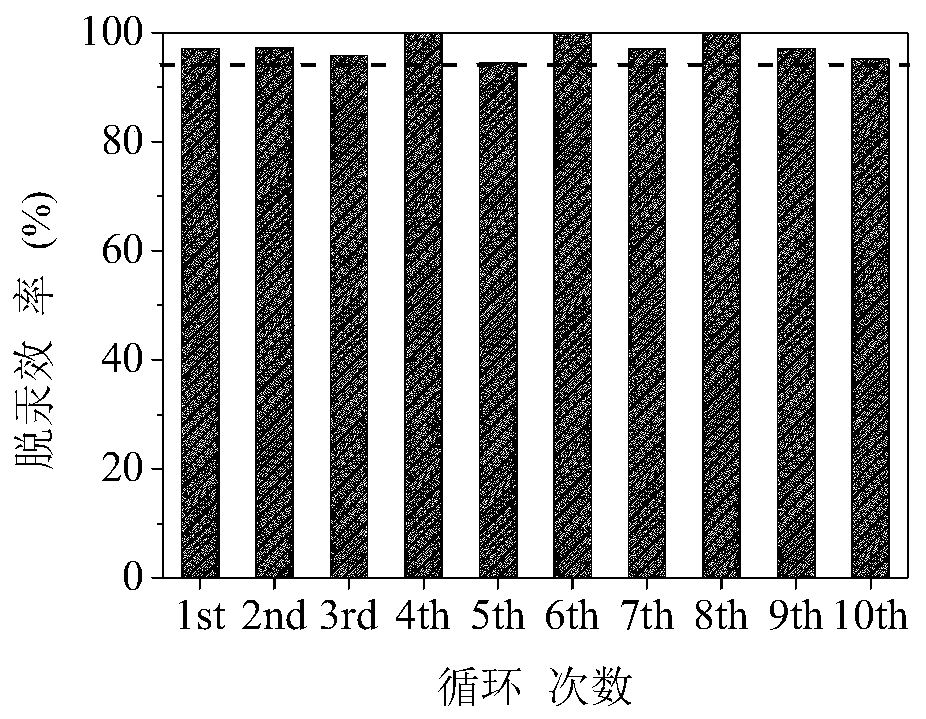

A kind of regenerable recycling mercury adsorbent and its preparation and regeneration method

ActiveCN107601570BLow costEasy to useOther chemical processesDispersed particle separationSorbentManganese

The invention belongs to the technical field of coal-fired flue gas pollutant control and discloses a renewable cyclic utilization mercury adsorbent as well as a preparation method and a regenerationmethod thereof. The mercury adsorbent is CuxMn(3-x)O4. The preparation method comprises the following steps: (1) dissolving copper substances and a chelating dispersant into deionized water to form amixed solution I, and forming chelating ions from copper ions; (2) putting dissoluble manganese substances into the mixed solution I to form a mixed solution II; (3) stirring the mixed solution II toform colloid, and drying and calcining the colloid; (4) grinding the colloid. The regeneration method comprises the following steps: (1) putting the mercury adsorbent after demercuration into a regeneration reactor; (2) introducing air flow; (3) performing condensation, and recycling monomer mercury; (4) adjusting the flow of the air flow, and regenerating activating substances on the surface of the mercury adsorbent. The mercury adsorbent provided by the invention can be recycled and regenerated, the regeneration method is simple, and the demercuration cost can be greatly reduced.

Owner:HUAZHONG UNIV OF SCI & TECH

Filter bag/filter element for removing mercury in flue gas as well as preparation method and application thereof

ActiveCN113731041ARich 3D pore-forming structureAchieve fixed removalDispersed particle filtrationSelenious AcidFlue gas

The invention discloses a filter bag / filter element for removing mercury in flue gas and a preparation method and application thereof. The filter bag / filter element is characterized in that a needled felt serves as main base cloth, selenite serves as a selenium source, the selenite is converted into nano-selenium to be loaded on a felt body in situ under the action of a reducing agent, the felt body is subjected to surface treatment and drying again after vacuum drying, and the filter bag / filter element is obtained; and the felt body is taken out, and is cut and sewed to obtain the filter bag / filter element. The filter bag / filter element provided by the invention has mercury removal and dust removal functions, not only can replace a traditional filter bag to simultaneously remove smoke dust and mercury in a cloth bag dust removal unit in a temperature interval of 50-200 DEG C, but also can be specially used as the filter bag / filter element for efficiently removing mercury in a mercury removal unit in a flue gas purification process.

Owner:CENT SOUTH UNIV

A filter bag/filter element for removing mercury in flue gas and its preparation method and application

ActiveCN113731041BShorten the purification processSave spaceDispersed particle filtrationTransportation and packagingSelenateSelenious Acid

The invention discloses a filter bag / filter element for removing mercury in flue gas and a preparation method and application thereof. Needle-punched felt is used as the main base cloth, selenite is used as a selenium source, and under the action of a reducing agent, the The selenate is converted into nano selenium and carried on the felt body in situ, the felt body is vacuum-dried and then subjected to surface treatment and then dried again, and the felt body is taken out and cut and sewn to obtain a filter bag / filter element. The filter bag / filter element of the present invention has both mercury removal and dust removal functions, which can not only replace the traditional filter bag to simultaneously remove smoke dust and mercury in the temperature range of 50-200°C in the bag dust removal unit, but also can be specially used in the flue gas purification process. The mercury removal unit is used as a filter bag / cartridge for efficient mercury removal.

Owner:CENT SOUTH UNIV

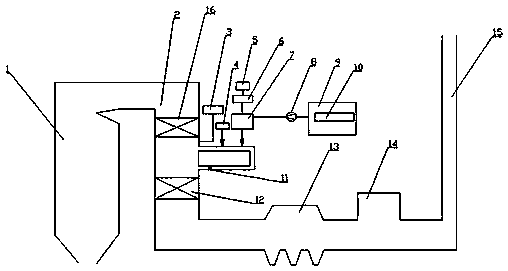

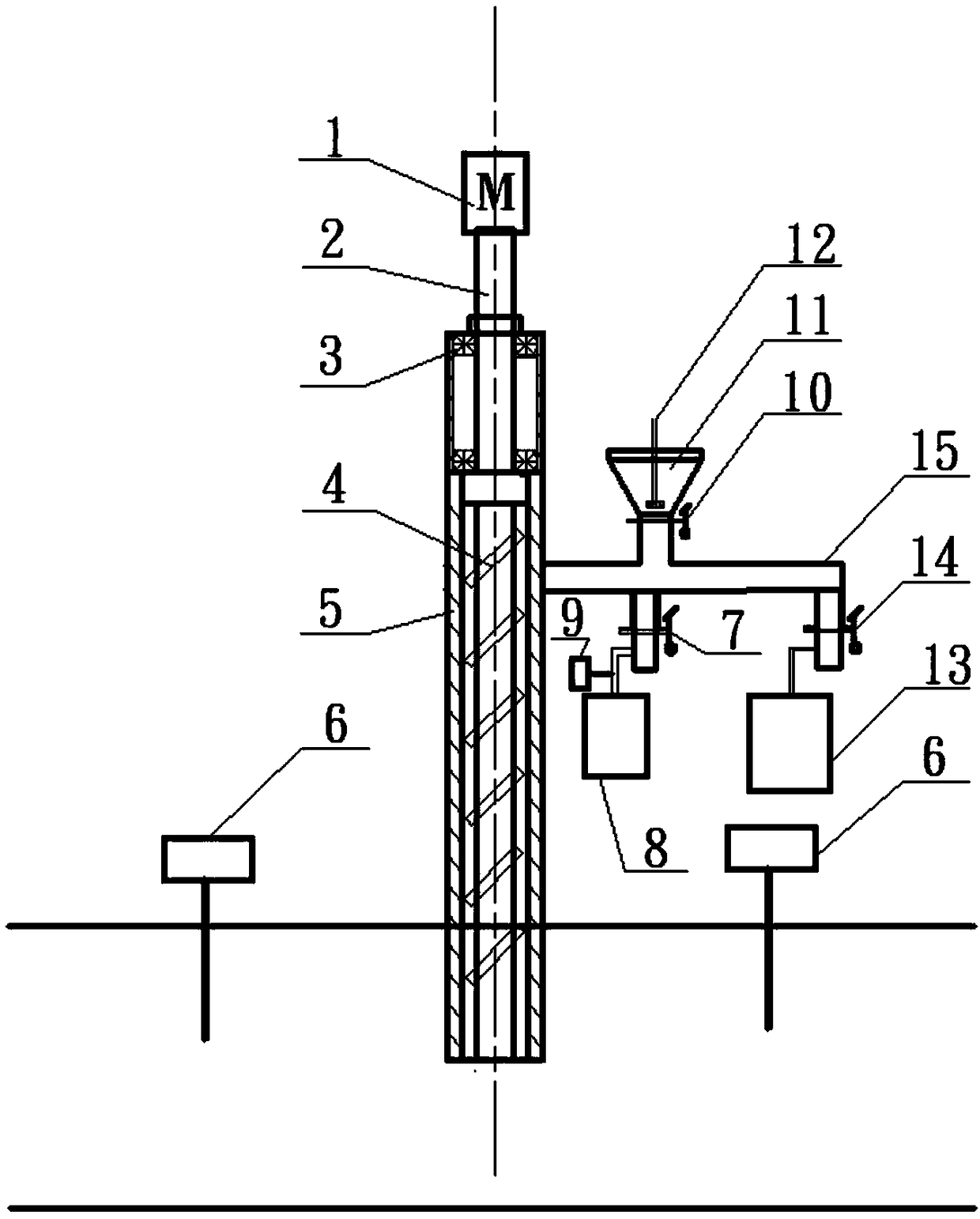

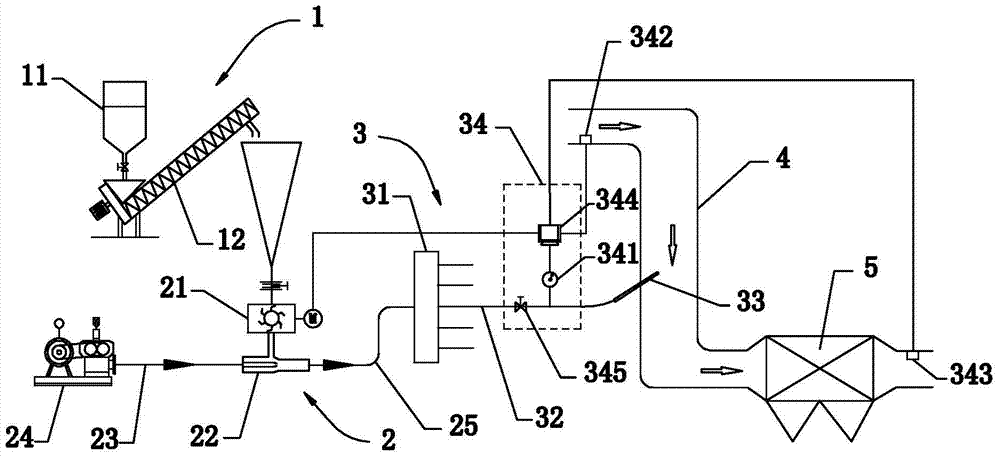

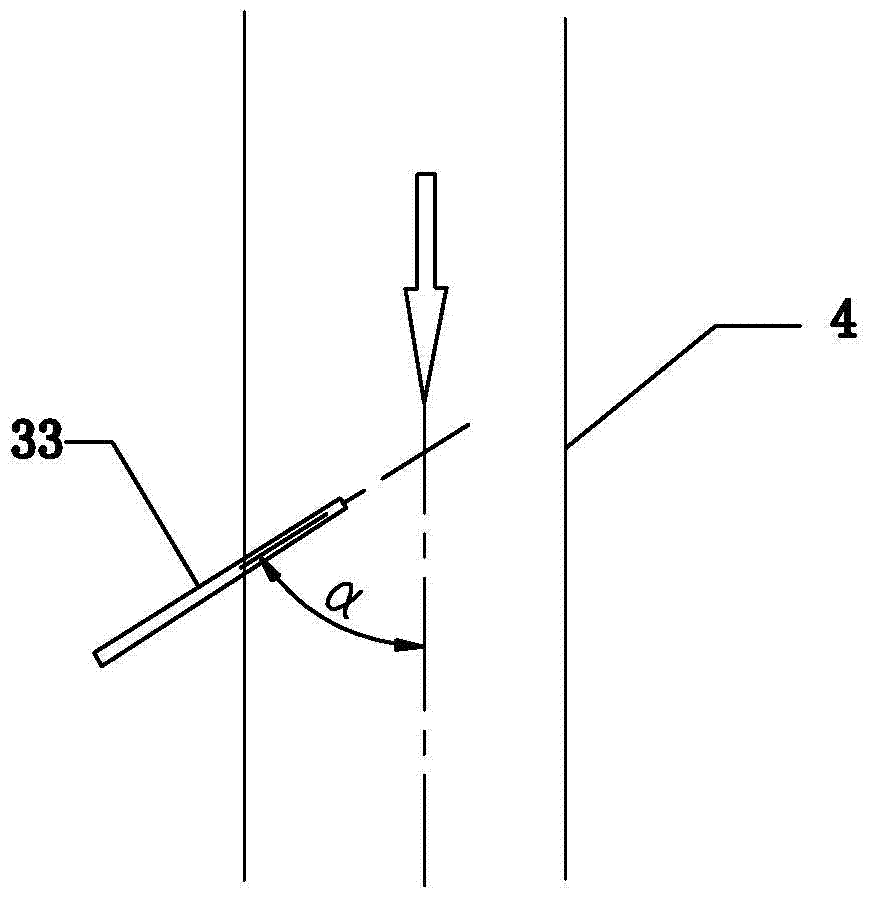

A coal-fired flue gas powder adsorbent injection mercury removal device

ActiveCN105126540BQuickly adjust the dosing ratioAvoid excessive additionDispersed particle separationFlue gasControl system

The invention belongs to the technical field of coal-fired flue gas purification, and in particular relates to a coal-fired flue gas powder adsorbent injection mercury removal device, which includes an adsorbent feeding part, an adsorbent powder conveying part and an adsorbent distribution injection part, wherein, The adsorbent feeding part includes a storage tank and a screw feeder; the adsorbent powder conveying part includes a frequency conversion feeder, a fan and an injector, and the ejector material is connected to the material conveying pipeline; The powder distributor is connected to several injection pipelines, and the injection pipeline is equipped with a spray gun and an intelligent flow control system. The invention can automatically and quickly adjust the dosing ratio of the powder adsorbent according to the mercury content in the flue gas, avoiding excessive or insufficient addition of the powder adsorbent, improving the effect of spraying mercury removal, reducing the waste of the powder adsorbent, and improving the The use efficiency of powder adsorbent reduces the cost of mercury removal.

Owner:山东默锐环境产业股份有限公司

Modified clay adsorbent and preparation method and application thereof

InactiveCN106475044ALarge specific surface areaImprove mercury removal efficiencyGas treatmentOther chemical processesSorbentFlue gas

The invention discloses a modified clay adsorbent and a preparation method and application thereof. The adsorbent consists of the following raw materials in parts by weight: 34-42 parts of clay, 2-6 parts of peregal O, 5-13 parts of salicylic acid and 13-21 parts of dipropylene glycol. The preparation method comprises the following steps: mixing and grinding the clay and the peregal O; then adding a dipropylene glycol solution; heating and stirring in a sealed manner, heating and dropwise adding the salicylic acid; after cooling, carrying out ultrasonic treatment; and stirring until the component is dry, and then calcining at high temperature to obtain the absorbent. The clay and the peregal O are mixed and ground, after the mixture is treated by the dipropylene glycol and the salicylic acid, the absorbent is prepared, the specific surface area is promoted to be increased, the modified clay adsorbent is applied to mercury treatment of flue gas, and the mercury removal efficiency is greatly improved and reaches 95% or above. The modified clay adsorbent is simple in process, short in technological process and low in cost, is conveniently popularized and used in a large range, and can be reused; and the mercury removal costs can be greatly reduced.

Owner:HENAN SHUIJINGTOU CULTURAL MEDIA CO LTD

Flue gas demercuration system and method based on discharge and activation of halogen materials

InactiveCN102580493BEfficient use ofEfficient removalDispersed particle separationParticulatesHalogen

Owner:ZHEJIANG UNIV

A device and method for removing mercury from flue gas by using polyvinyl chloride and boiler fly ash

InactiveCN103423757BImprove removal effectImprove mercury removal efficiencyLighting and heating apparatusDispersed particle separationAir preheaterSorbent

The invention provides a flue gas demercuration device and method utilizing polyvinyl chloride and boiler fly ash. The flue gas demercuration device comprises a boiler furnace, a flue and a chimney, wherein the boiler furnace, the flue and the chimney are connected in sequence, and an economizer, an air preheater, an electrostatic dust collector and a wet desulphurization tower are arranged on the flue in sequence. The flue gas demercuration device further comprises a flue gas mercury on-line monitor, a circulation flue, a crushing device, a gasification device, an air heater, a feeding device and an intelligent control device, wherein the circulation flue is arranged on the flue between the economizer and the air preheater, a discharge port of the feeding device is connected to the circulation flue, and the feeding device comprises a polyvinyl chloride waste material feeding machine and an adsorbent feeding machine. According to the flue gas demercuration device and method utilizing the polyvinyl chloride and the boiler fly ash, hydrogen chloride generated by a polyvinyl chloride waste material is used for oxidizing zero-valent mercury into gaseous divalent mercury, and then the boiler fly ash is used for adsorbing flue gas mercury. On the premise that large-scale reconstruction is not conducted on an existing pollution control device, the flue gas demercuration device and method utilizing the polyvinyl chloride and the boiler fly ash can greatly improve the demercuration effect and demercuration efficiency, thereby lowering demercuration cost, and realizing environment-friendly utilization of the polyvinyl chloride waste material.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

Absorbing liquid for mercury removal from flue gas containing mercury and method for removing mercury from flue gas containing mercury

ActiveCN106268258BEfficient removalEfficient oxidation removalDispersed particle separationSodium stearateThiourea

The invention discloses an absorption liquid for removing mercury from mercury fume and a mercury removal method for the mercury fume. The absorption liquid is prepared from components as follows: iodide ions, thiourea compounds, formamidine disulphide and sodium stearate, the mercury fume is contacted with the absorption liquid for a reaction, and elemental mercury and mercury in the oxidation state in the mercury fume enter the absorption liquid. Accordingly, elemental mercury and mercury in the oxidation state in the mercury fume are removed efficiently simultaneously, the absorption liquid is particularly applicable to processing of fume with high content of mercury, and the mercury removal efficiency is 90% or higher.

Owner:CENT SOUTH UNIV

Modified kaolin adsorbent, and preparation method and application of modified kaolin adsorbent

InactiveCN106732334AHigh specific surface areaImprove mercury removal efficiencyGas treatmentOther chemical processesSorbentTannin

The invention discloses a modified kaolin adsorbent, and a preparation method and an application of the modified kaolin adsorbent. The adsorbent comprises the following raw materials in parts by weight: 34-42 parts of kaolin, 2-6 parts of peregal O, 5-13 parts of tannin and 13-21 parts of dipropylene glycol. The preparation method comprises the steps of mixing and grinding the kaolin and the peregal O, then adding a dipropylene glycol solution for sealing, heating and stirring, heating up, dropwise adding the tannin, performing ultrasonic treatment after cooling, stirring to dryness, and performing high temperature calcination to form the adsorbent. The adsorbent is prepared by mixing and grinding the kaolin and the peregal O and treating with dipropylene glycol and tannin; the specific surface area is increased; the adsorbent is applied to smoke mercury treatment; and the demercuration efficiency is greatly improved and reaches above 95%. The adsorbent is simple in technology, short in technical process, low in cost and convenient to popularize and use extensively, and can be recycled, and the demercuration cost can be lowered greatly.

Owner:ZHENGZHOU LIFUAI BIOLOGICAL TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com