Absorbing liquid for mercury removal from flue gas containing mercury and method for removing mercury from flue gas containing mercury

A technology of mercury flue gas and absorbing liquid, applied in the field of pyrometallurgy flue gas treatment, can solve the problems of difficult to overcome influence, high cost of ionic liquid, high volatility, etc. The effect of saturated mercury absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

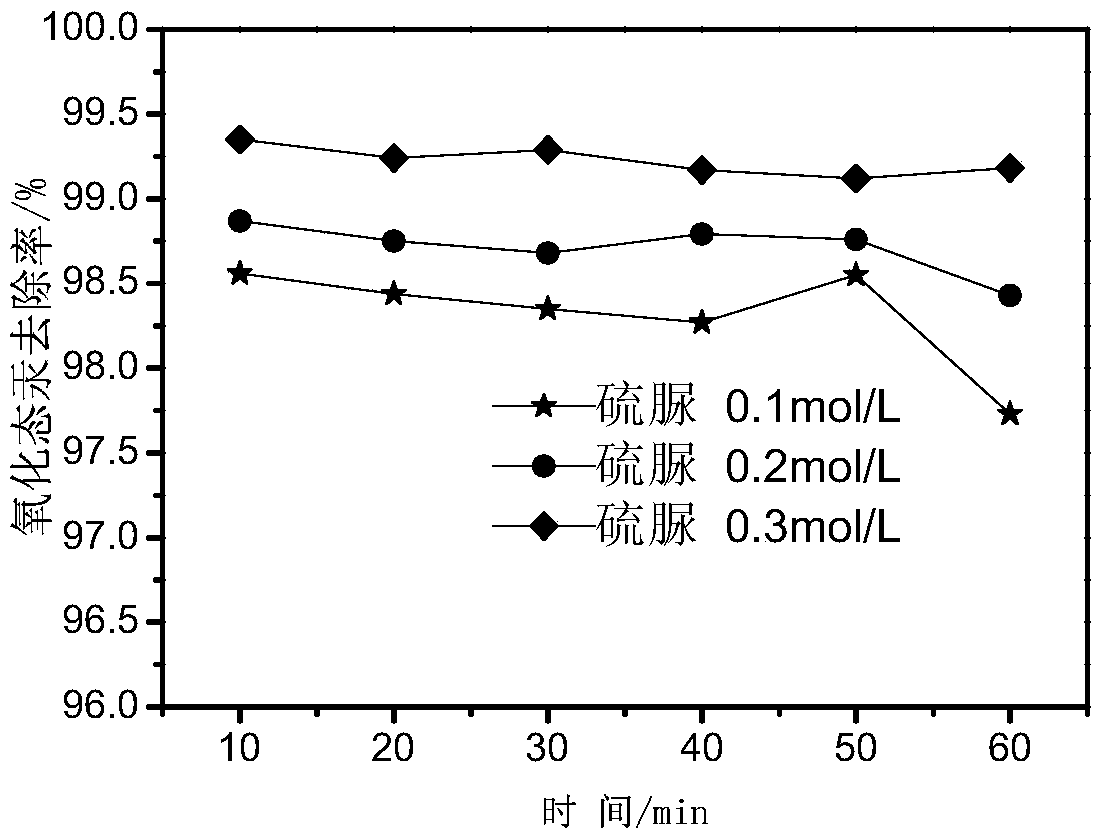

[0034] The temperature of the flue gas used in this implementation is 45°C, and the main component content (volume) of the flue gas: SO 2 4%, O 2 5%, Hg 2+ 1mg / Nm 3 , and the rest are N 2 . Mercury adsorption solution washing composition: the content of thiourea compounds is 0.1mol / L, 0.2mol / L, 0.3mol / L respectively, the iodide ion content is 0.01mol / L, the pH of the washing solution is 2.0, and the content of dithioformamidine is 0.01mol / L, sodium stearate 0.001mol / L. The mercury-containing flue gas with a gas flow rate of 1L / min was injected into a scrubbing solution with a volume of 500mL to simulate the flue gas scrubbing process, and the reaction time was 60min. After washing, the removal effect of mercury in the flue gas is as follows: figure 1 shown. From figure 1 It can be seen from the figure that when the content of thiourea is 0.1mol / L, the removal efficiency of mercury adsorption solution to divalent mercury ions in flue gas is above 97%. With the increas...

Embodiment 2

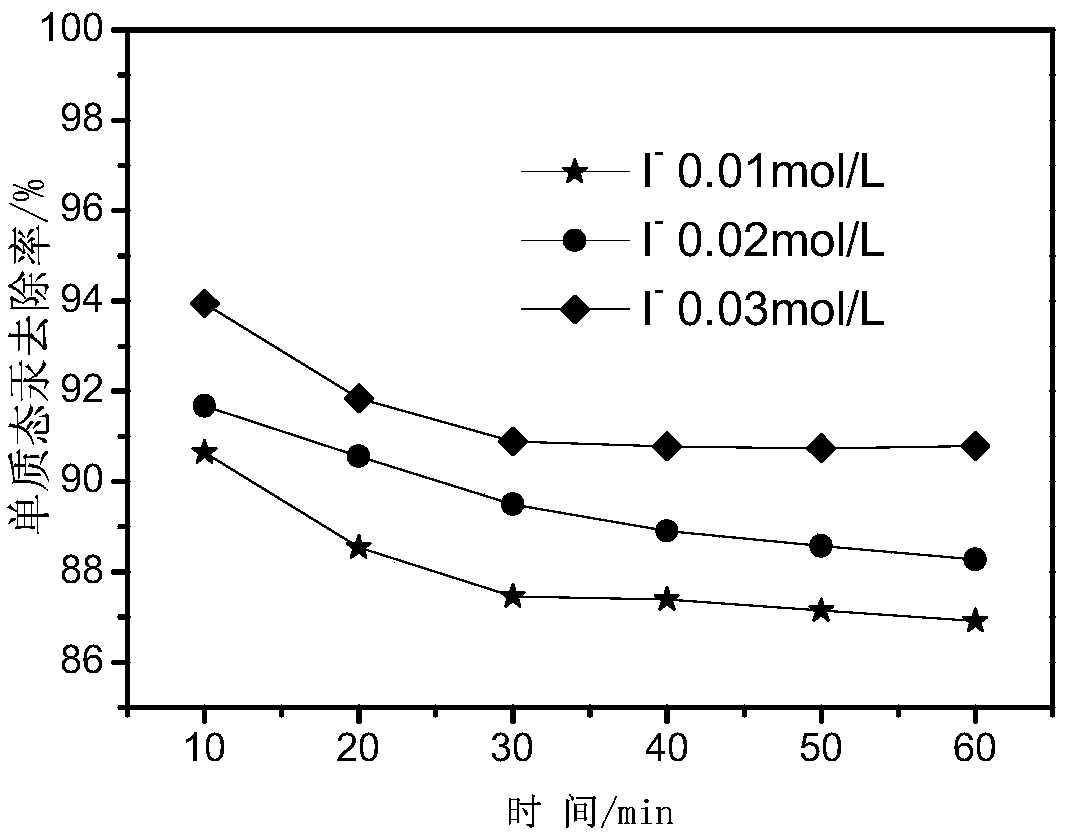

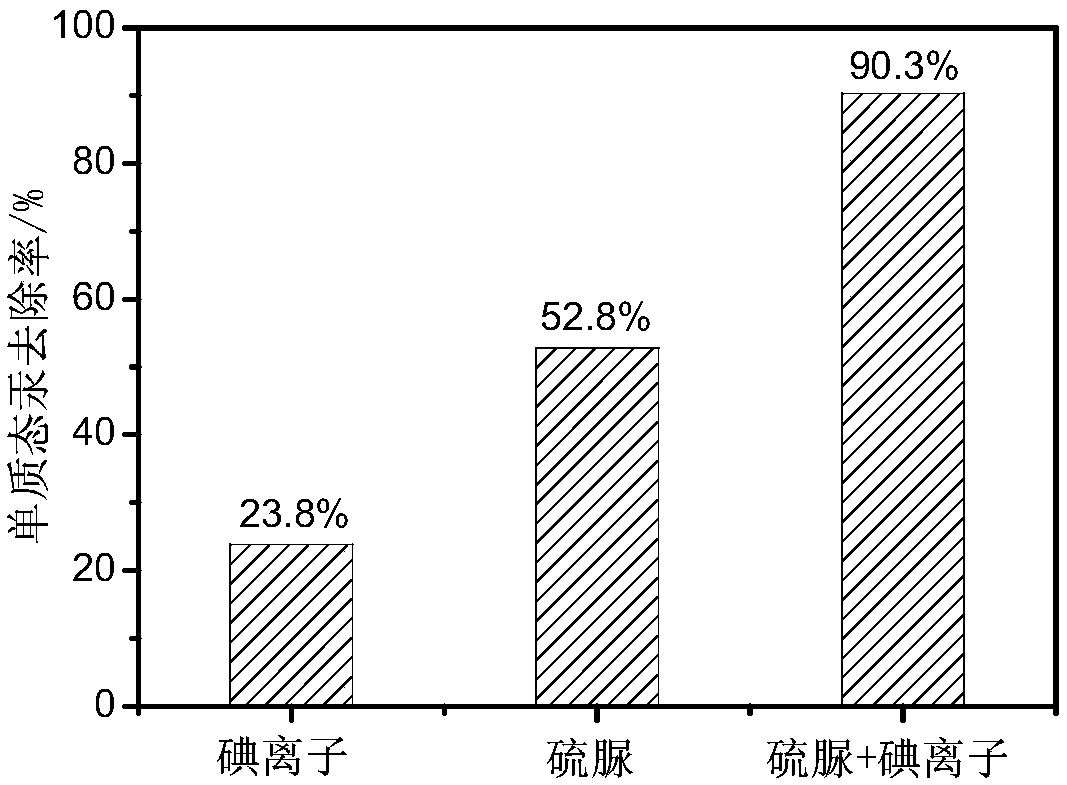

[0036] The temperature of the flue gas used in this implementation is 35°C, and the main component content (volume) of the flue gas: SO 2 4%, O 2 5%, Hg 0 450μg / Nm 3 , CO 2 3%, the rest is N 2. Mercury adsorption solution washing composition: the content of thiourea compound is 0.2mol / L, the iodide ion content is 0.01mol / L, 0.02mol / L, 0.03mol / L respectively, the pH of the washing solution is 1.5, and the content of dithioformamidine is 0.01mol / L, sodium stearate 0.002mol / L. The mercury-containing flue gas with a gas flow rate of 0.6L / min was passed into a scrubbing solution with a volume of 500mL to simulate the flue gas scrubbing process, and the reaction time was 60min. After washing, the removal effect of mercury in the flue gas is as follows: figure 2 shown. From figure 2 It can be seen that the mercury adsorption solution has a high removal efficiency for elemental mercury. When the iodide ion content is 0.03mol / L and the dithioformamidine content is 0.015m...

Embodiment 3

[0037] The temperature of the flue gas used in this implementation is 25°C, and the main component content (volume) of the flue gas: SO 2 2%, O 2 6%, Hg 0 450μg / Nm 3 , CO 2 3%, the rest is N 2 . Mercury adsorption solution washing components: the content of thiourea compounds is 0.2mol / L, the iodide ion content is 0.01mol / L, the pH of the washing solution is 1.5, and the content of dithioformamidine is 0, 0.005mol / L, 0.01mol / L respectively L, 0.015mol / L, sodium stearate content is 0.002mol / L. The mercury-containing flue gas with a gas flow rate of 0.6L / min was passed into a scrubbing solution with a volume of 500mL to simulate the flue gas scrubbing process, and the reaction time was 60min. As a result, it was found that when dithioformamidine was not included in the solution, the removal efficiency of the washing solution to elemental mercury was only 64.5%, but after adding 0.005mol / L dithioformamidine in the solution, the removal efficiency of elemental mercury ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com