Flue gas mercury removal device

A technology for mercury removal and flue gas removal, applied in separation methods, dispersed particle separation, chemical instruments and methods, etc., can solve the problems of low utilization rate, low capacity, and high cost of activated carbon, and achieve low implementation cost, high mercury removal efficiency, and high efficiency. The effect of convenient maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

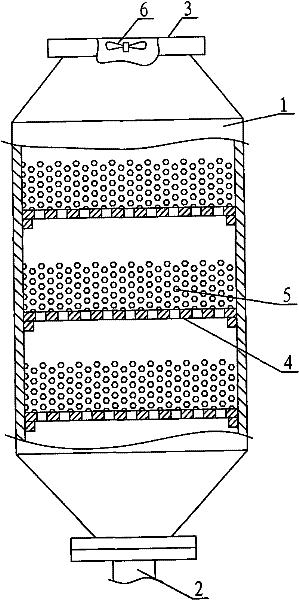

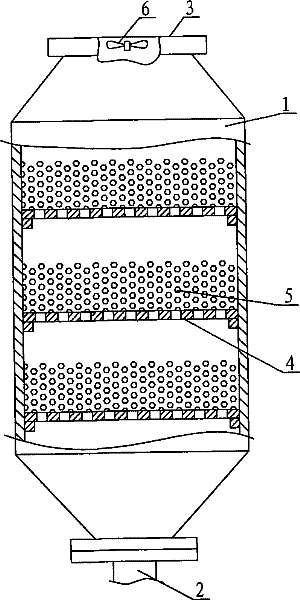

[0019] Specific implementation mode one: as figure 1 As shown, a flue gas mercury removal device includes a reactor shell 1, the lower part of the reactor shell 1 is provided with an air inlet 2, and the upper part is provided with an air outlet 3, wherein the inner cavity of the reactor shell 1 is Three layers of porous support plates 4 are arranged between the air port 2 and the air outlet 3 , and each support plate 4 is provided with an adsorption packing layer 5 . During implementation, described air outlet 3 places are provided with aspirator 6, and during specific implementation, described aspirator 6 also can be arranged in the pipeline that communicates with air outlet; The adsorption filler in described adsorption filler layer 5 is composed of activated carbon particles .

[0020] In order to verify the technical solution of this embodiment and optimize the specific parameter settings, the applicant, based on the above-mentioned device structure, changed the porous s...

specific Embodiment approach 2

[0027]Embodiment 2: In Embodiment 2, on the basis of Embodiment 1, the adopted adsorption filler is replaced by a new type of adsorption filler independently developed by the applicant, and the rest of the implementation conditions remain unchanged. The new adsorption filler includes the following preparation steps: using 72% of fly ash, 7% of calcium oxide, 3% of sodium bromide, 12% of Hunan clay, 3% of polyethylene, and 3% of rice husk to mix, mix Add water and mix thoroughly, then extrude and granulate to form granules with a particle diameter of 30-50mm, and then sinter and shape at a high temperature of 900-1100°C.

[0028] First, in order to verify and optimize the mercury absorption effect of the new adsorption filler, the applicant conducted a large number of tests to optimize the parameters such as the molding particle size, sintering temperature, and sintering holding time during the preparation process of the above-mentioned new adsorption filler. During the experim...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com