Coal-fired flue gas heavy metal pollutant removal device

A technology for coal-fired flue gas and heavy metals, applied in gas treatment, membrane technology, and separation of dispersed particles, can solve problems such as dust emission, environmental and human health hazards, reduce mercury removal costs, improve catalytic efficiency, and provide Effect of Mercury Efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described in detail below through specific embodiments in conjunction with the accompanying drawings.

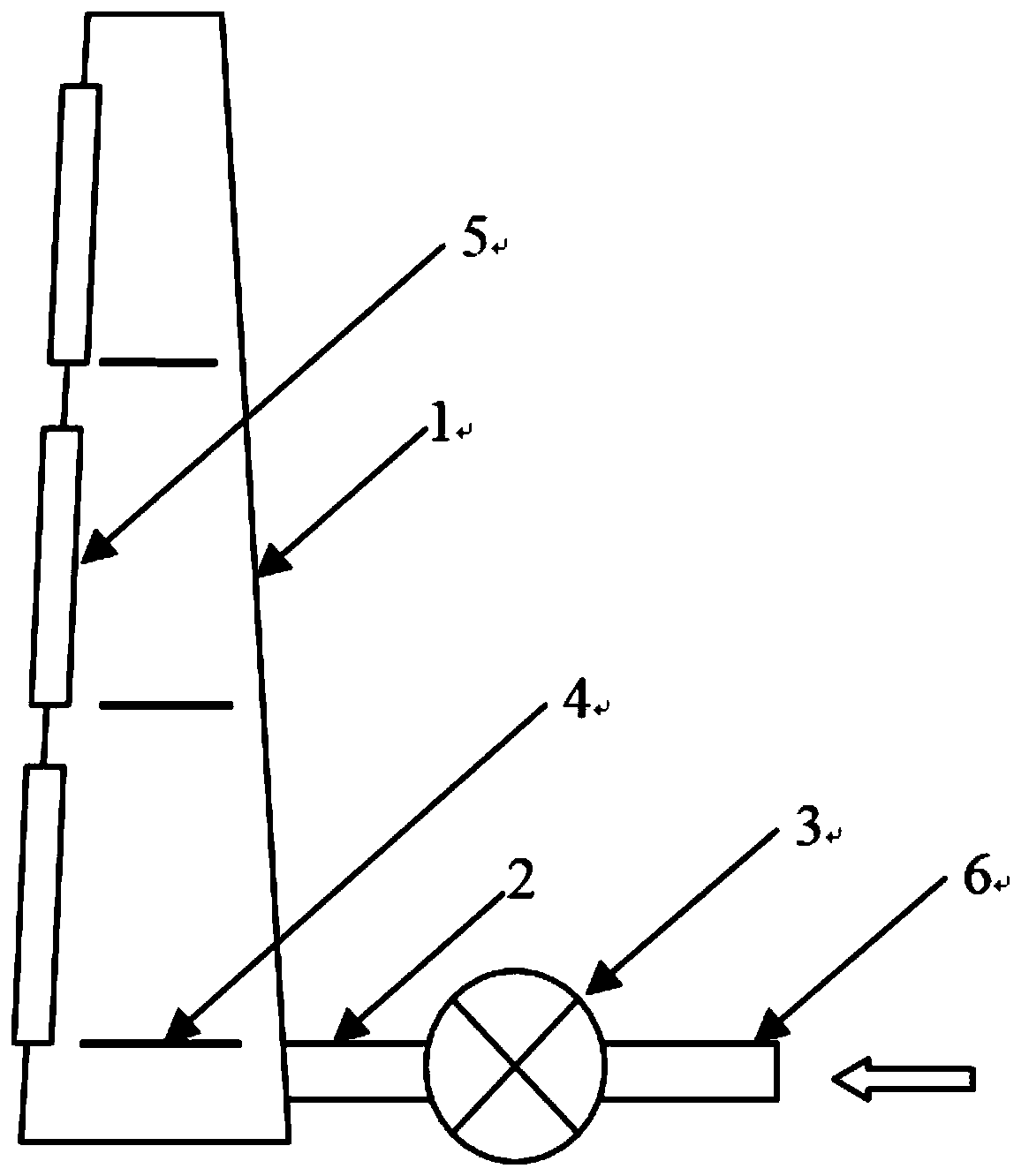

[0022] Such as Figure 1-2 As shown, the embodiment of the present invention is a device for removing heavy metal pollutants from coal-fired flue gas, which includes:

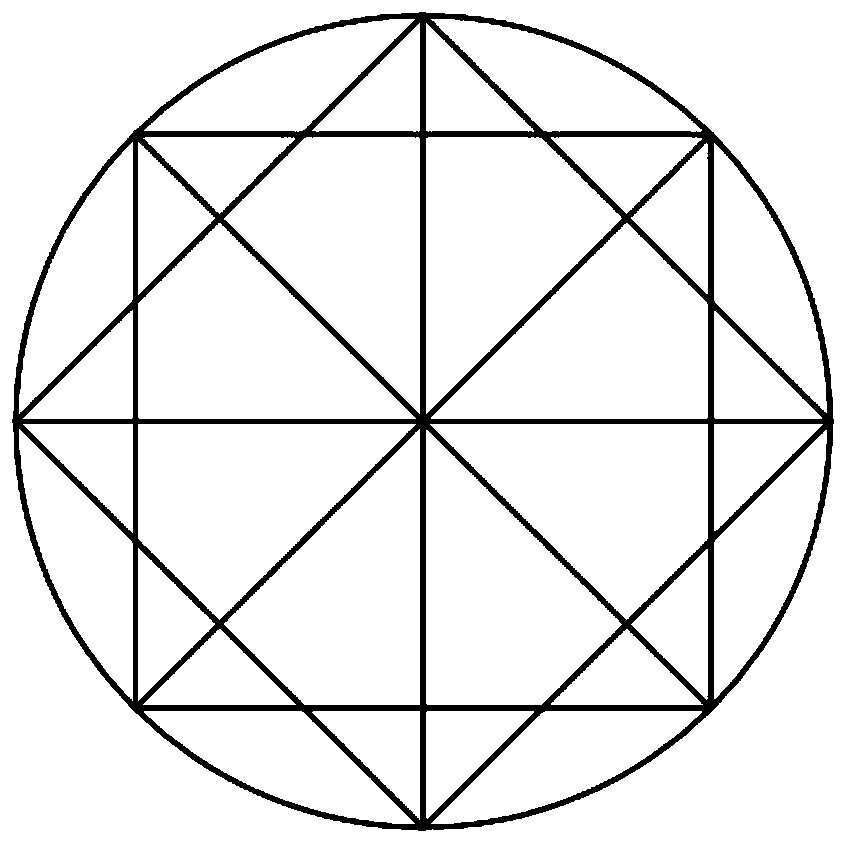

[0023] There are multiple grilles 4, and the multiple grilles 4 are arranged inside the chimney 1 at equal intervals along the height direction of the chimney 1;

[0024] Transparent glass 5, which is matched with the grille 4, and the transparent glass 5 is provided on the chimney wall above the corresponding grille 4;

[0025] The first pipe 2, the inlet end of which is connected with the outlet end of the induced draft fan 3, and the outlet end of the first pipe 2 is connected with the bottom of the chimney 1;

[0026] The inlet end of the second pipe 6 is connected with the electrostatic precipitator, and the outlet end of the second pipe 6 is connected with the inlet en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com