A method for removing elemental mercury in coal-fired flue gas

A coal-fired flue gas and elemental mercury technology, applied in the field of flue gas purification, can solve the problems of low operating pH, increased cost of mercury removal, and large amount of absorbent

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

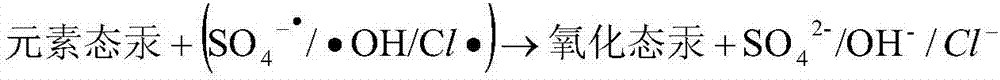

Problems solved by technology

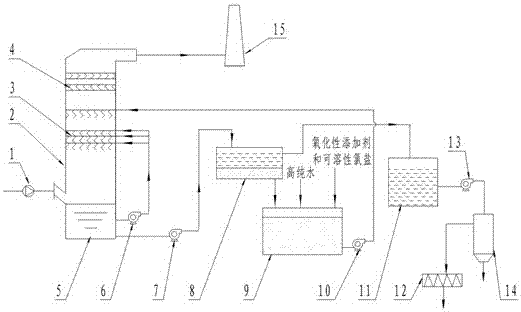

Method used

Image

Examples

Embodiment 1

[0037] Example 1: Weigh 100 g of the magnetic catalyst cobalt-doped bismuth ferrite according to the ratio (the molar ratio of cobalt atoms and iron atoms in cobalt-doped bismuth ferrite is 1:9), 200 g of oxidizing additive sodium persulfate, and 200 liters of high-purity water , mix the magnetic catalyst with high-purity water, ultrasonically disperse for 1 minute, adjust the pH to 6, then add a proportioned amount of oxidizing additives at room temperature, and stir mechanically for 3 minutes to prepare the absorbent.

Embodiment 2

[0038] Example 2: Weigh 50 g of magnetic catalyst cobalt-doped bismuth ferrite (the molar ratio of cobalt atoms to iron atoms in cobalt-doped bismuth ferrite is 3:7), 50 g of cobalt / lanthanum doped bismuth ferrite (cobalt-doped bismuth ferrite) The mol ratio of cobalt atom, lanthanum atom, iron atom in lanthanum-doped bismuth ferrite is 3:1:6), oxidizing additive sodium perborate 300g, potassium hydrogen persulfate compound salt 200g, high-purity water 380 liters, magnetic The catalyst is mixed with high-purity water, ultrasonically dispersed for 2 minutes, and the pH is adjusted to 12. Then, at room temperature, a proportioned amount of oxidizing additive is added, and mechanically stirred for 4 minutes to obtain the absorbent.

Embodiment 3

[0039] Embodiment 3: Take by weighing 100g of magnetic catalyst bismuth ferrite, 300g of oxidative additive potassium hydrogen persulfate compound salt, 280 liters of high-purity water, mix magnetic catalyst with high-purity water, ultrasonically disperse for 3 minutes, adjust pH to 7, and then Under the condition of room temperature, adding the proportioning amount of oxidative additives and stirring mechanically for 5 minutes, the absorbent is prepared.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com