Patents

Literature

54results about How to "Avoid re-release" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

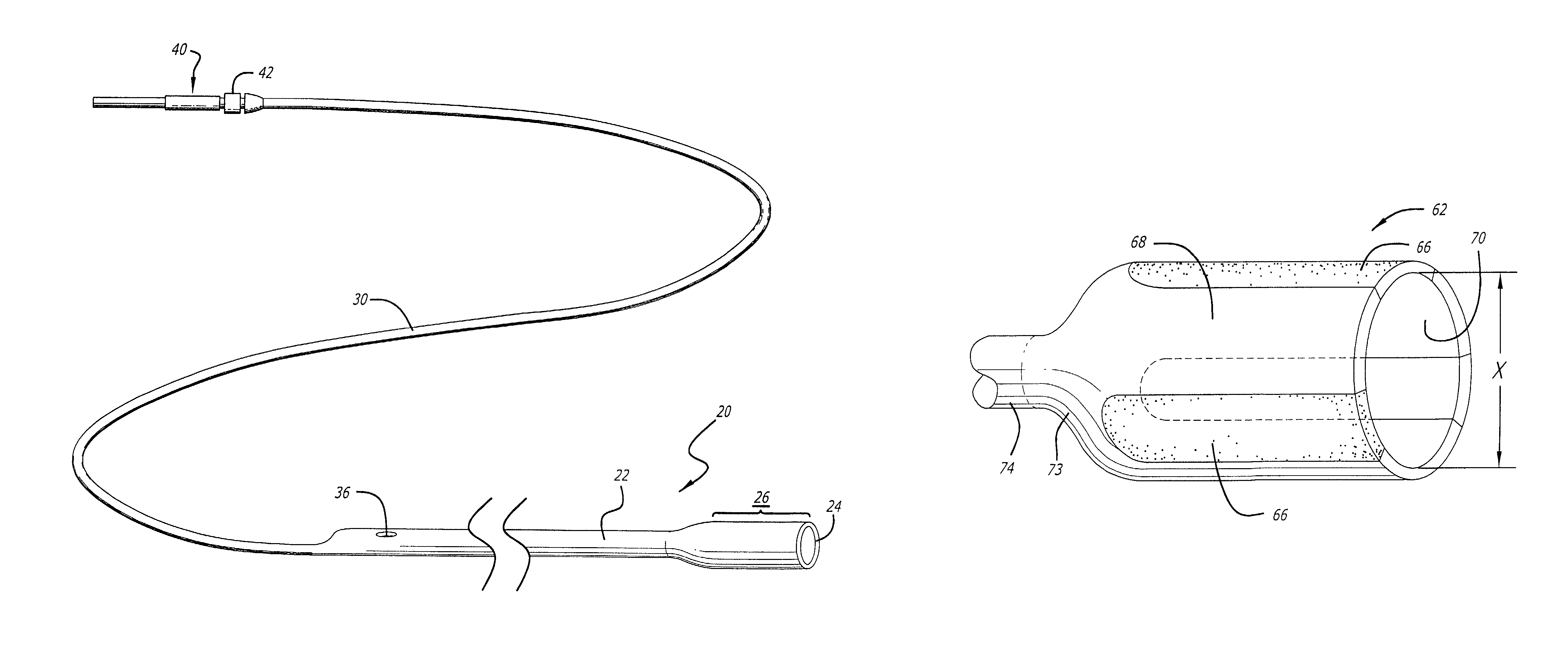

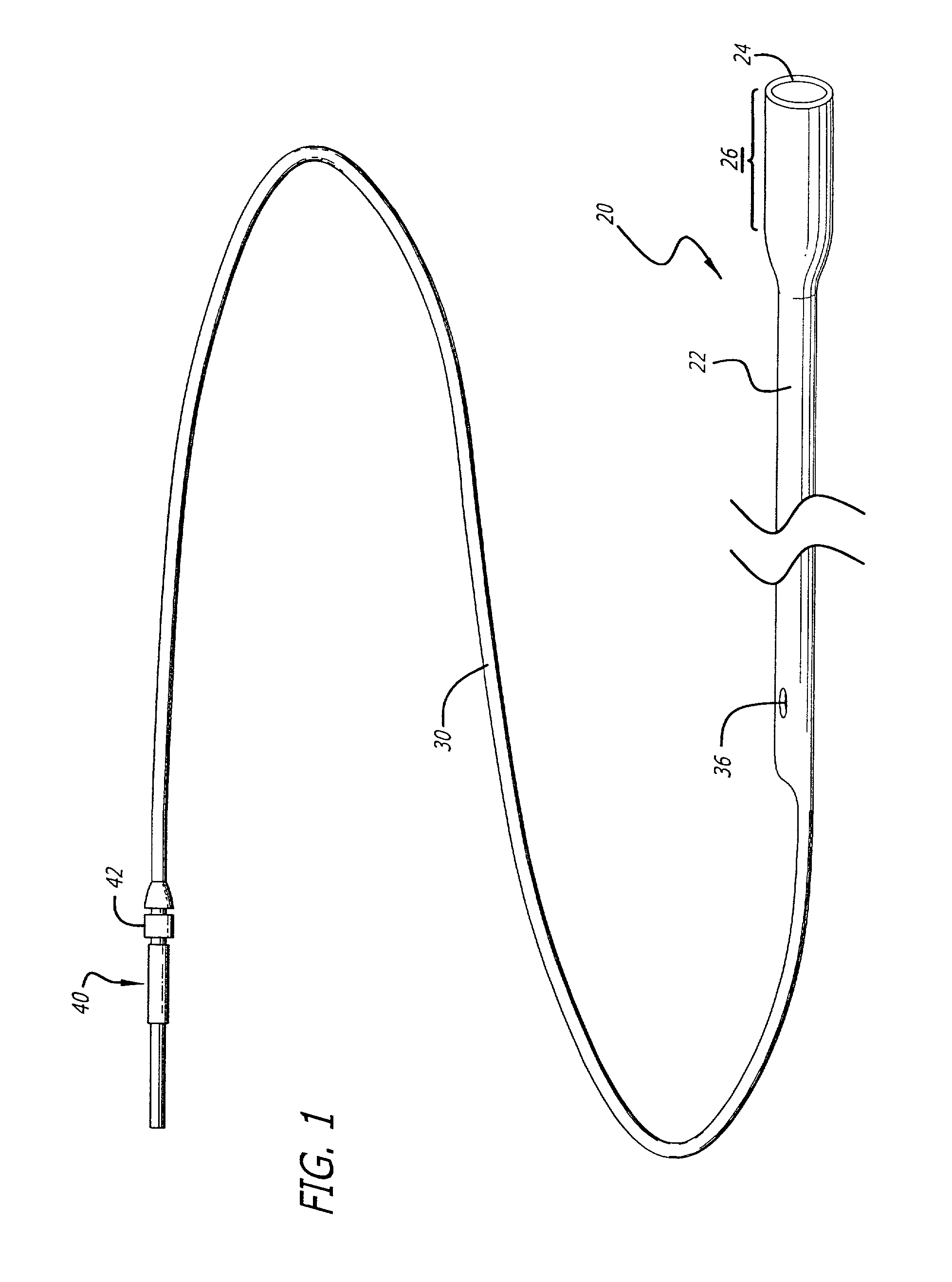

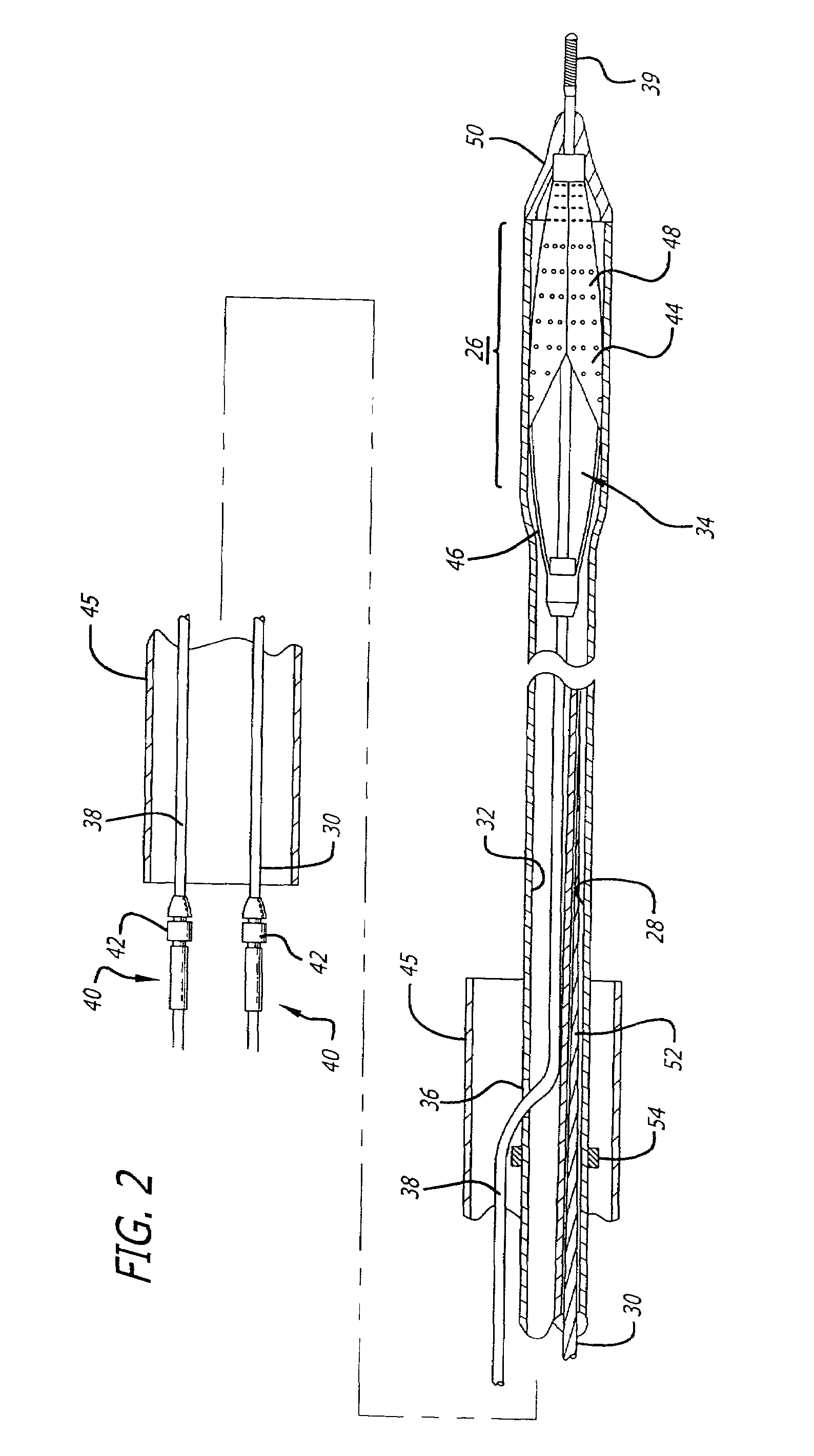

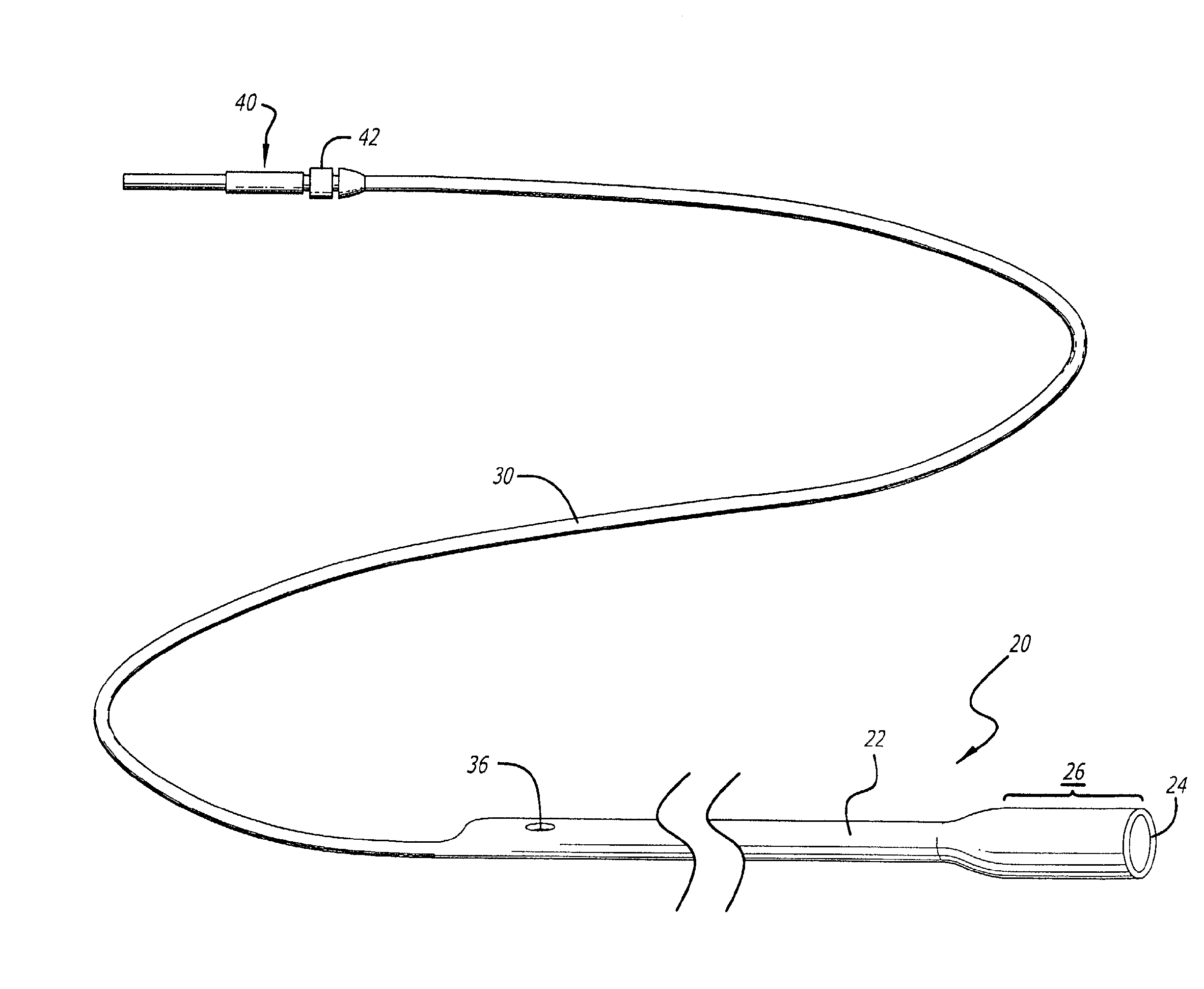

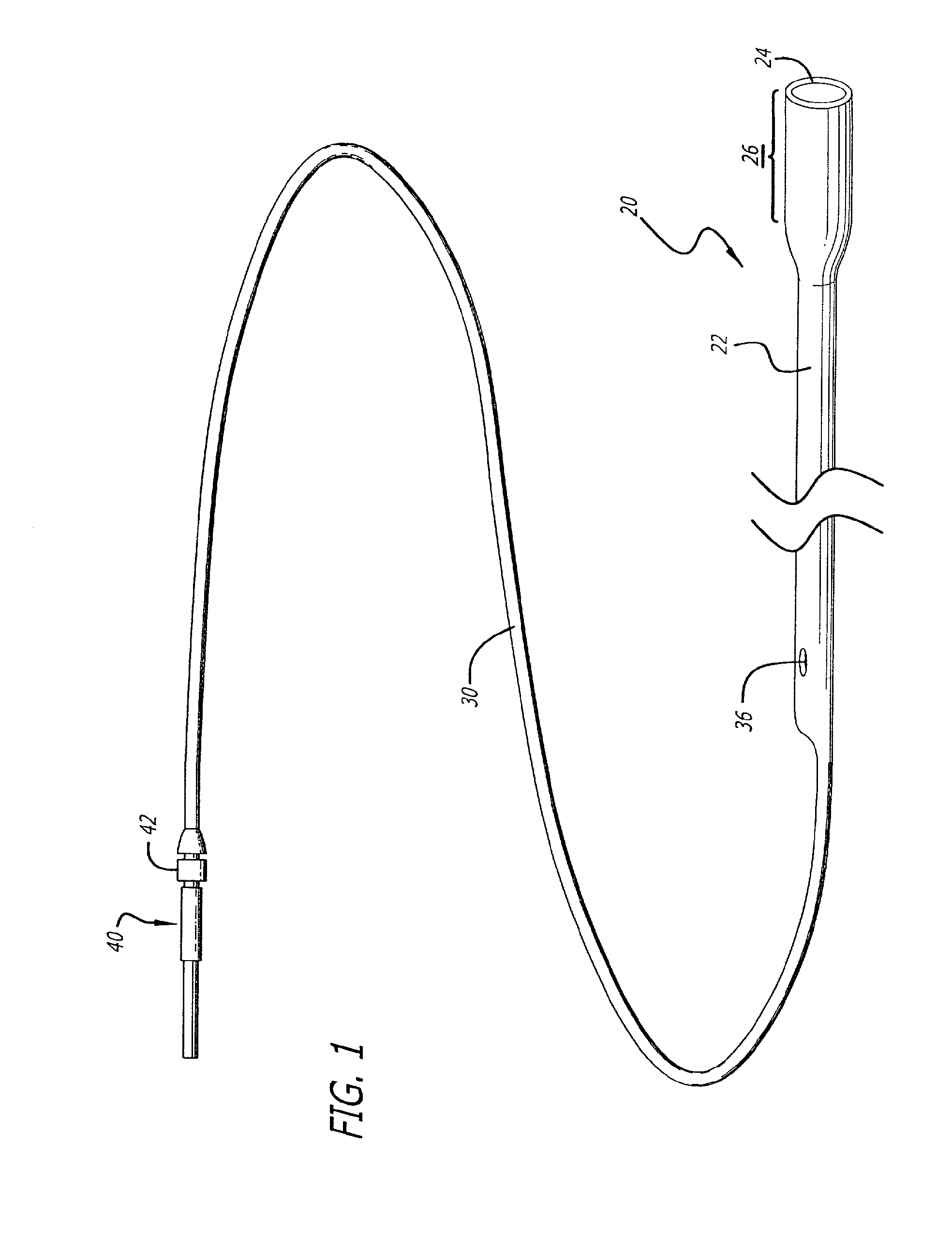

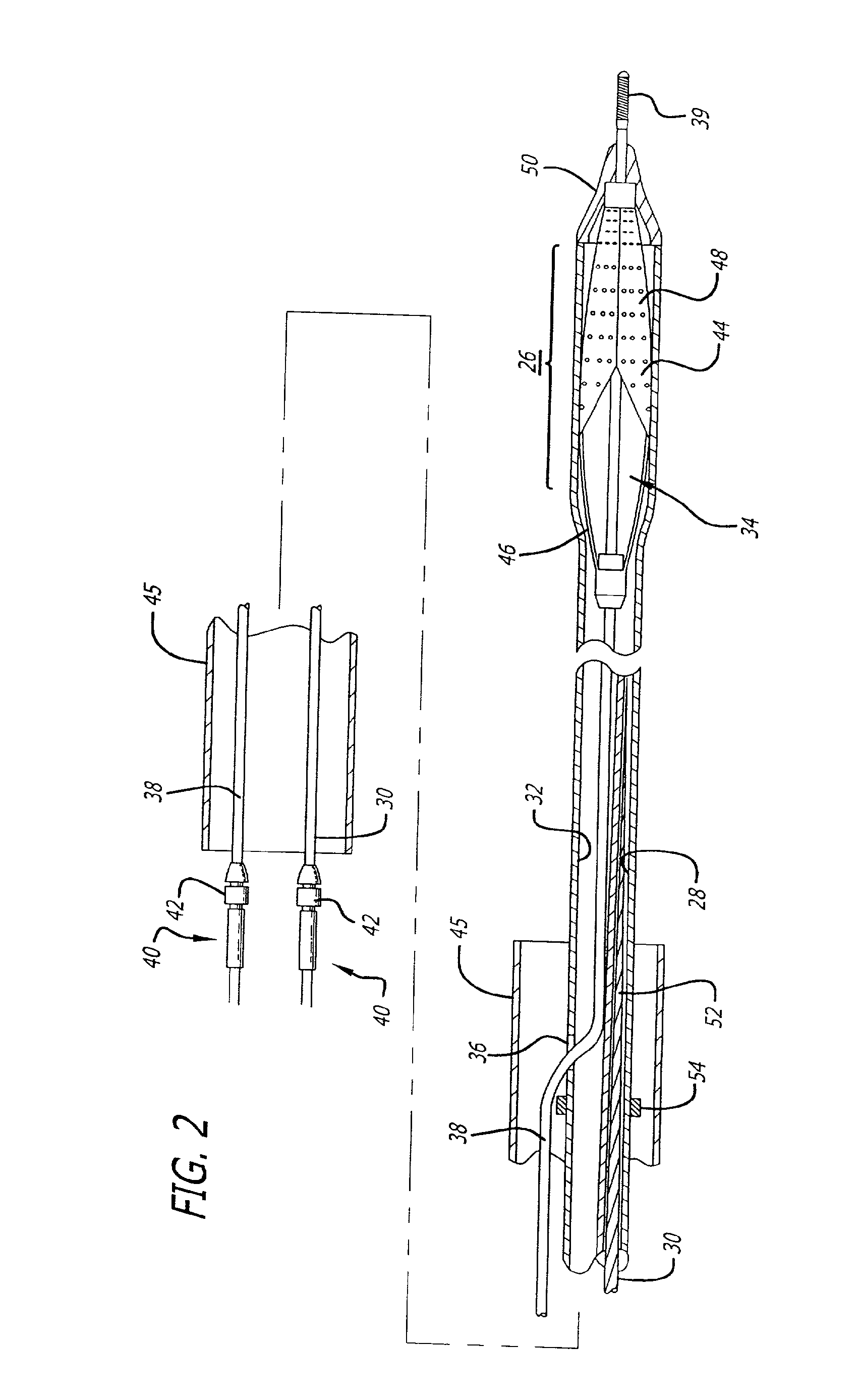

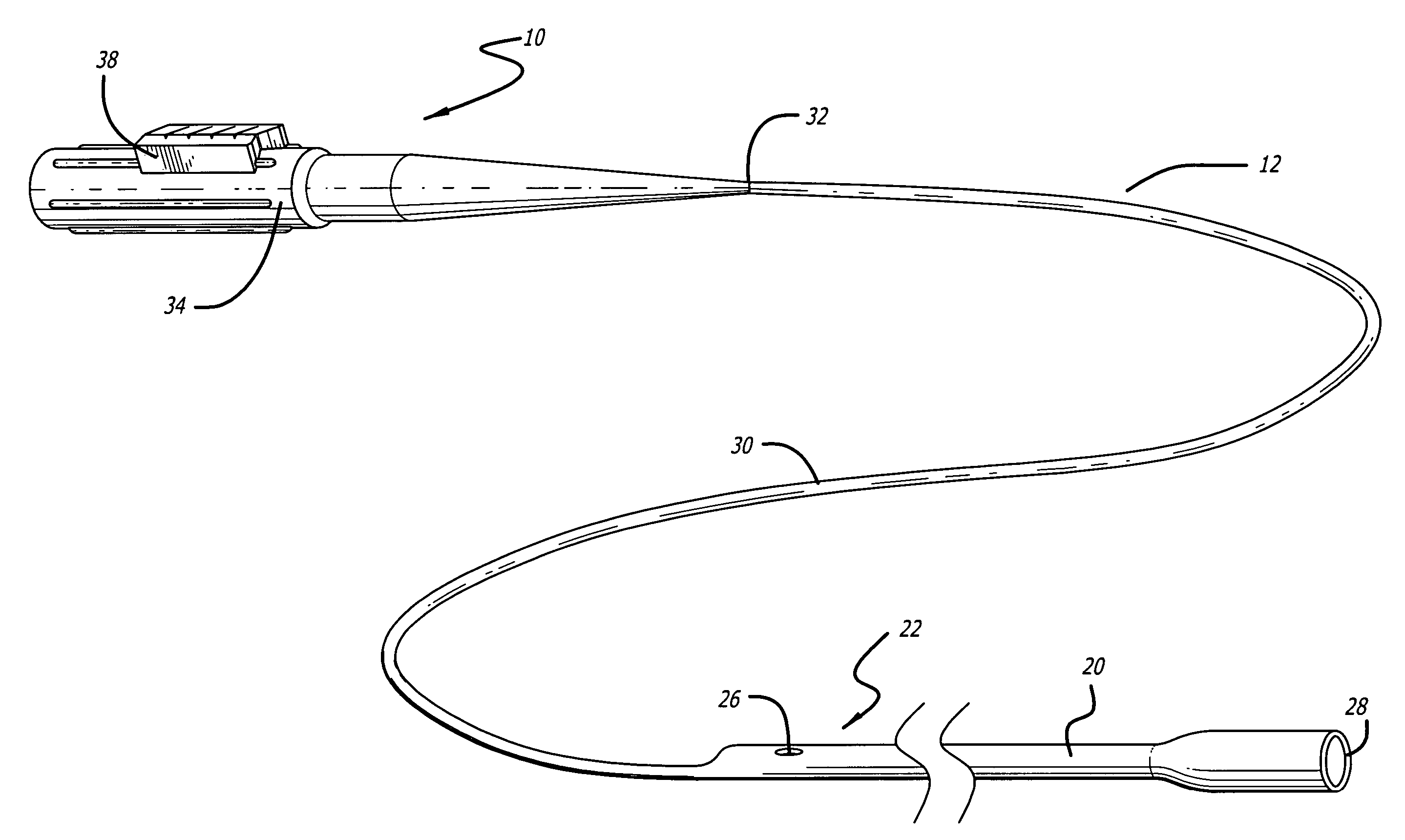

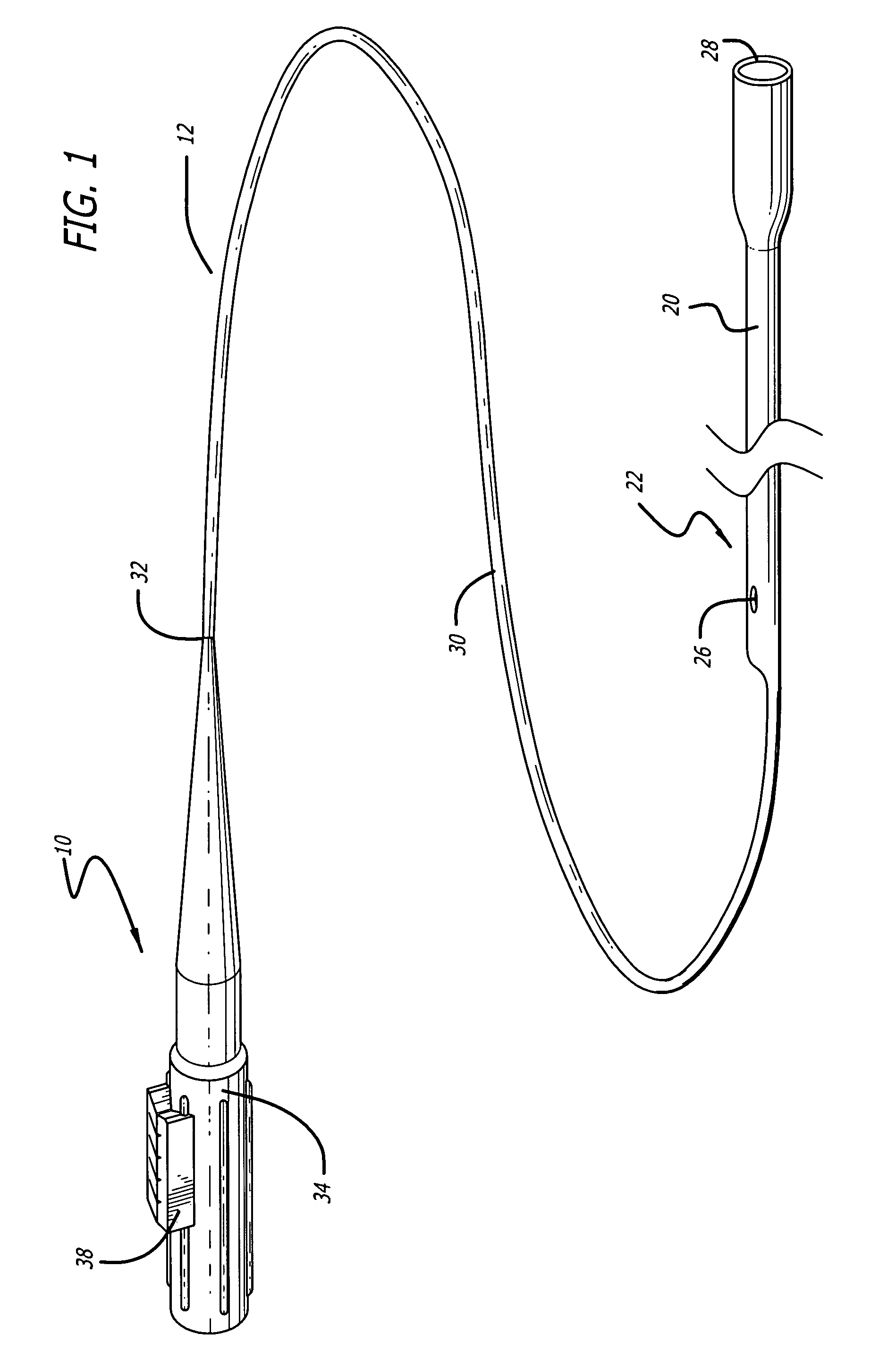

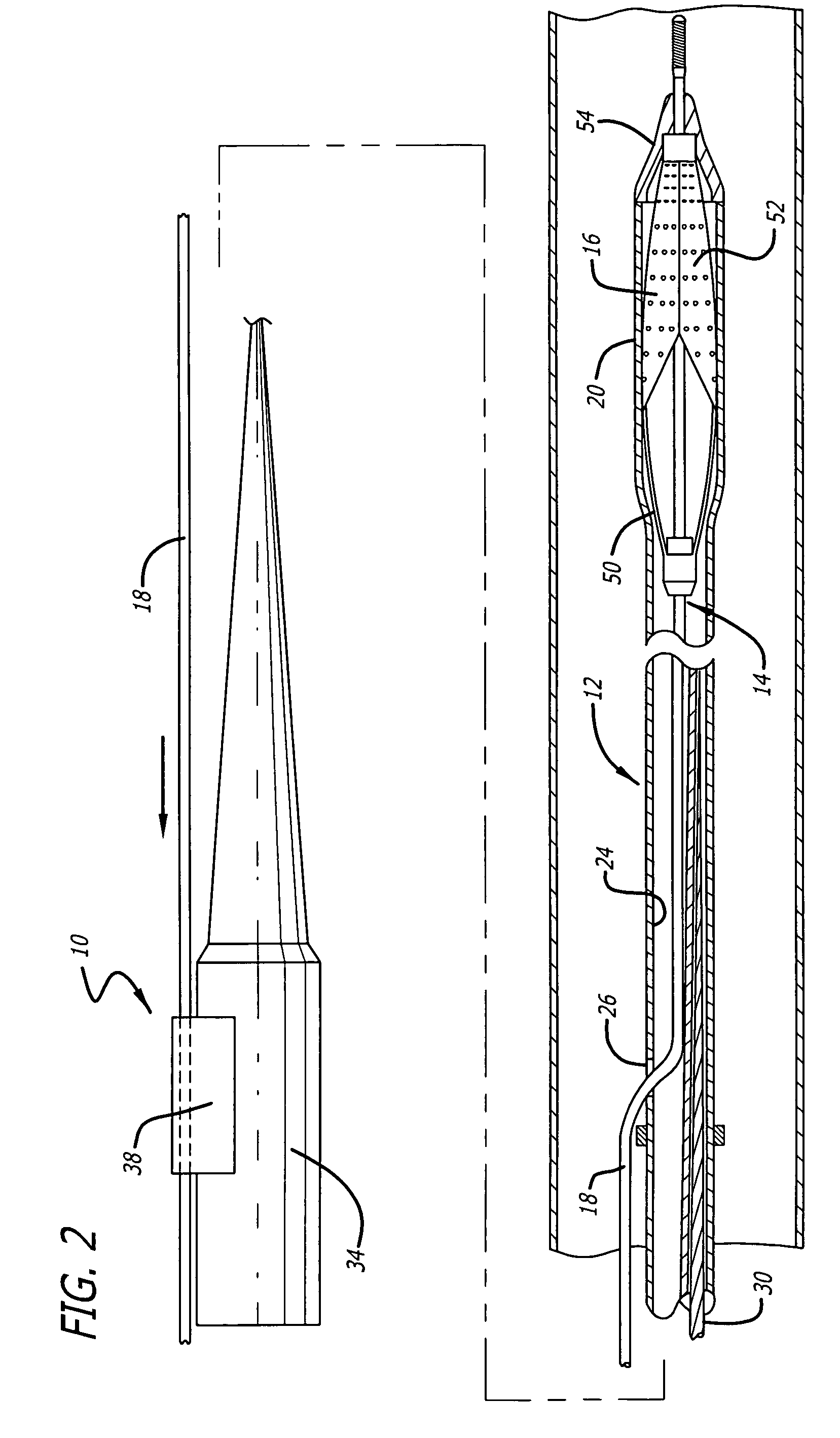

Delivery and recovery sheaths for medical devices

A deployment control system provides controlled deployment of an embolic protection device which may include a guide wire, an expandable filter attached to the guide wire near its distal end, and a restraining sheath that maintains the expanded filter in a collapsed position. The deployment control system includes a torque control device which allows the physician to torque the guide wire into the patient's anatomy and a mechanism for preventing the guide wire from buckling as the restraining sheath is being retracted to deploy the expandable filter. A recovery control system for recovering the embolic protection device includes an inner catheter which extends within a lumen of an outer recovery sheath in a coaxial arrangement. A distal portion of the inner catheter extends beyond another recovery sheath during advancement of the recovery system into the vasculature. The recovery sheath can be advanced over the inner catheter to collapse the expandable filter. The proximal ends of the inner catheter and recovery sheath include handle portions having snap mechanisms which hold the components together as the recovery system is being advanced into the patient's vasculature.

Owner:ABBOTT CARDIOVASCULAR

Process for preparing bentonite dephosphorization water purification agent

InactiveCN101264955AGranular performance is stableAvoid re-releaseWater/sewage treatment by ion-exchangeWater/sewage treatment by flocculation/precipitationWater bathsSodium Bentonite

A preparation method of bentonite phosphorus removal water purifying agent comprises the steps of drying calcium bentonite or sodium bentonite, pulverizing, sieving with 200 mesh sieve, adding a lanthanum salt solution, stirring in a water bath with room temperature to 60 DEG C for 2-12 hours, washing, and preparing into 5-10 wt% slurry; adding inorganic polymeric flocculant into the above slurry, and stirring; filtering; and drying the filter cake at 70-90 DEG C, and pulverizing to 40-200 mesh powder as bentonite phosphorus removal water purifying agent. The inventive method modifies bentonite with inorganic polymeric flocculant and lanthanum salt, so as to enhance the precipitation, coagulation and flocculation action of the bentonite phosphorus removal water purifying agent through the synergism among the inorganic polymeric flocculant, lanthanum salt and bentonite. The inventive method is simple; and the obtained bentonite phosphorus removal water purifying agent has high efficiency and good safety, and has important application value in environmental protection and controlling of water bodies such as river, lake and water reservoir.

Owner:TSINGHUA UNIV

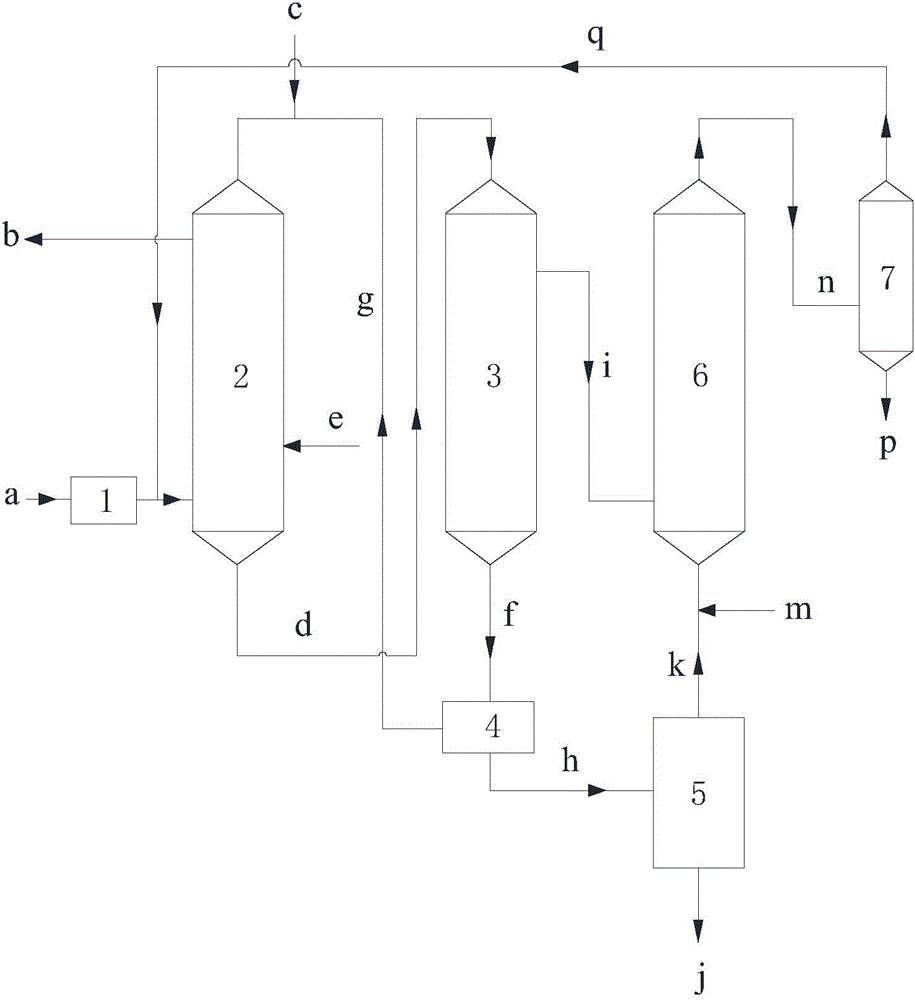

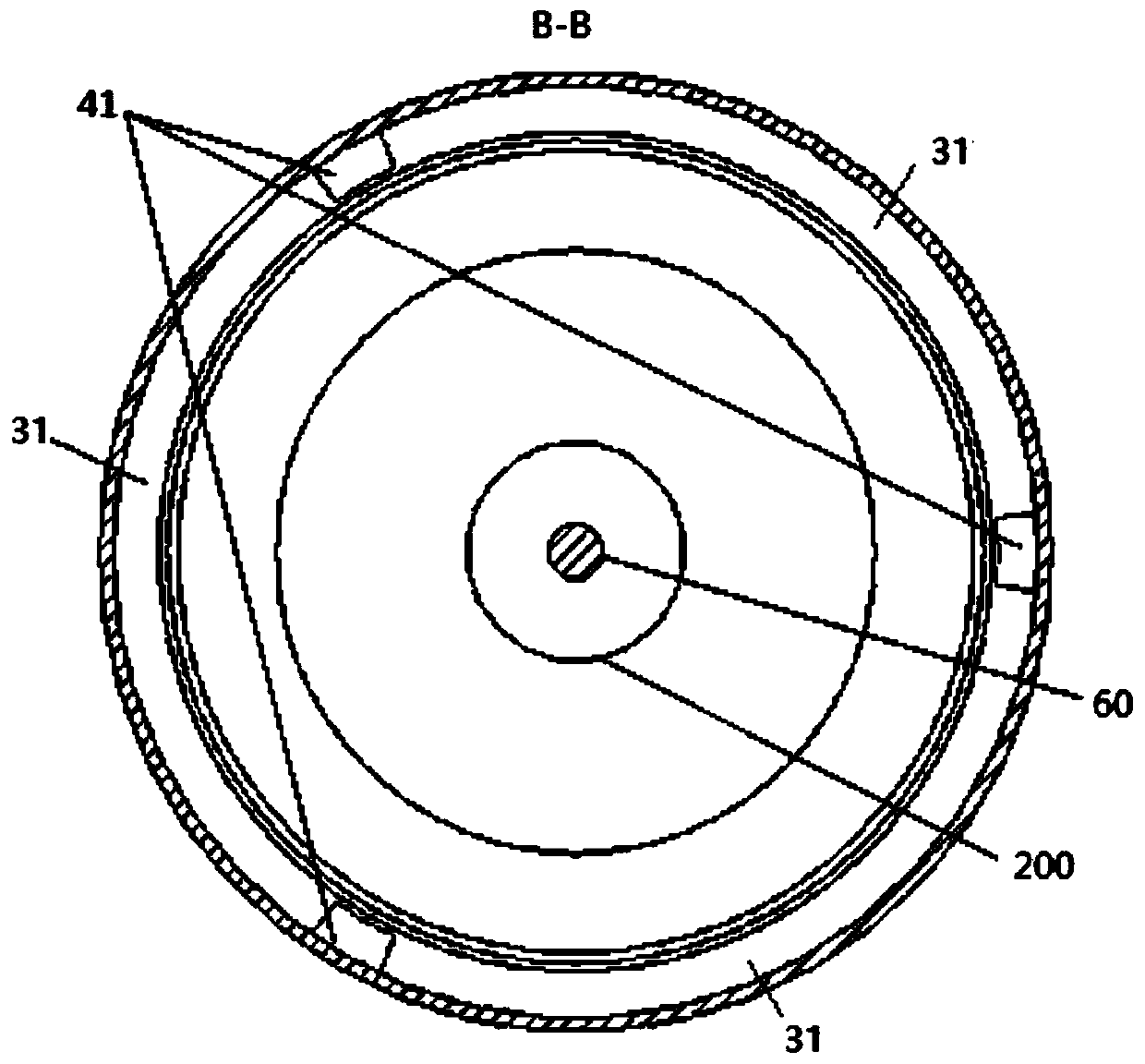

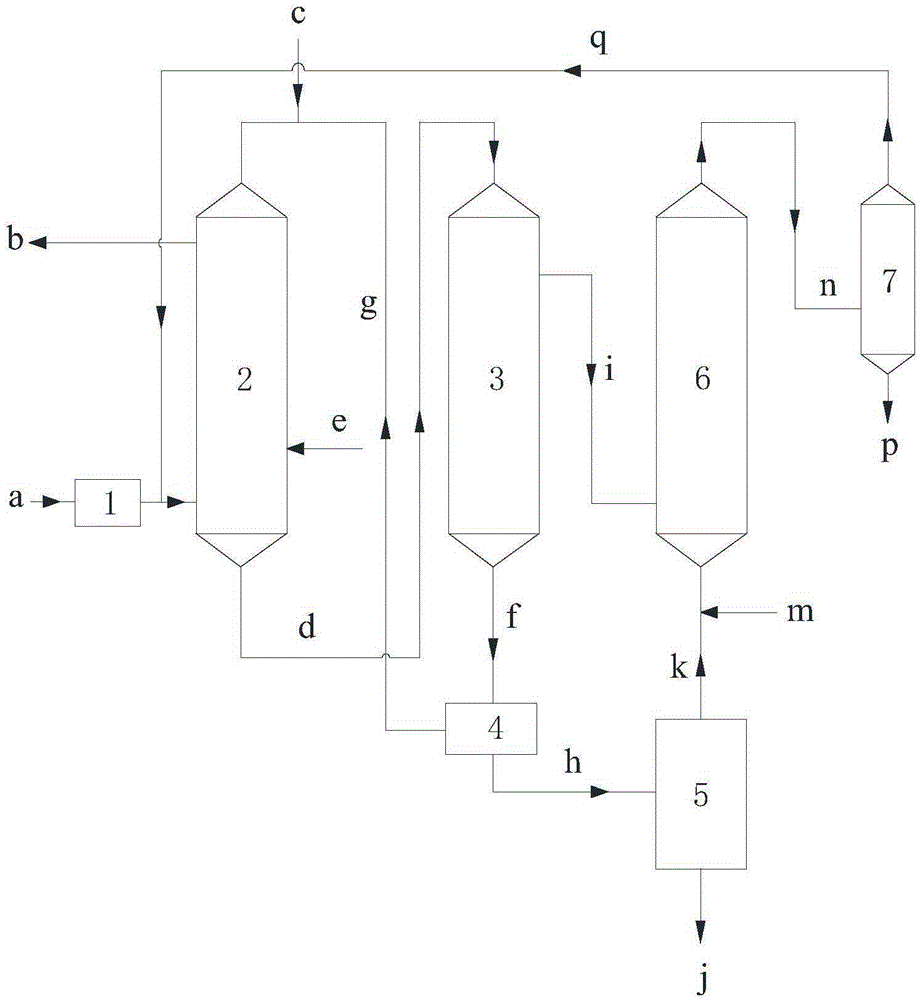

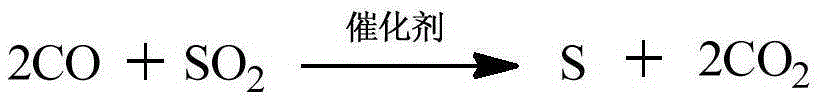

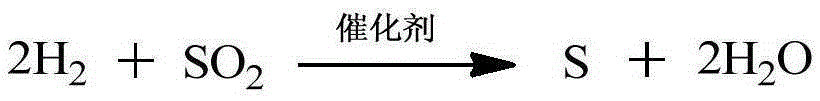

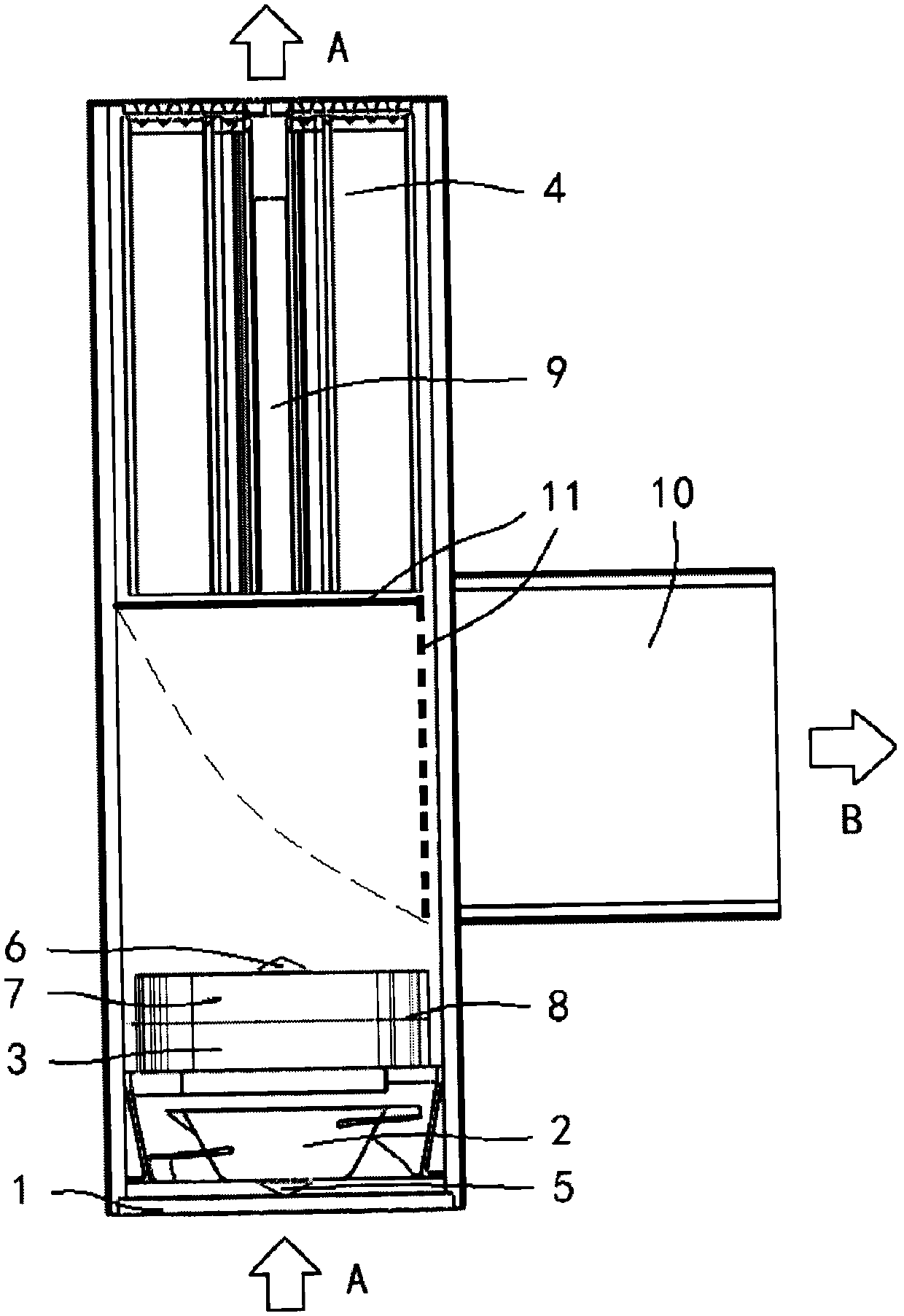

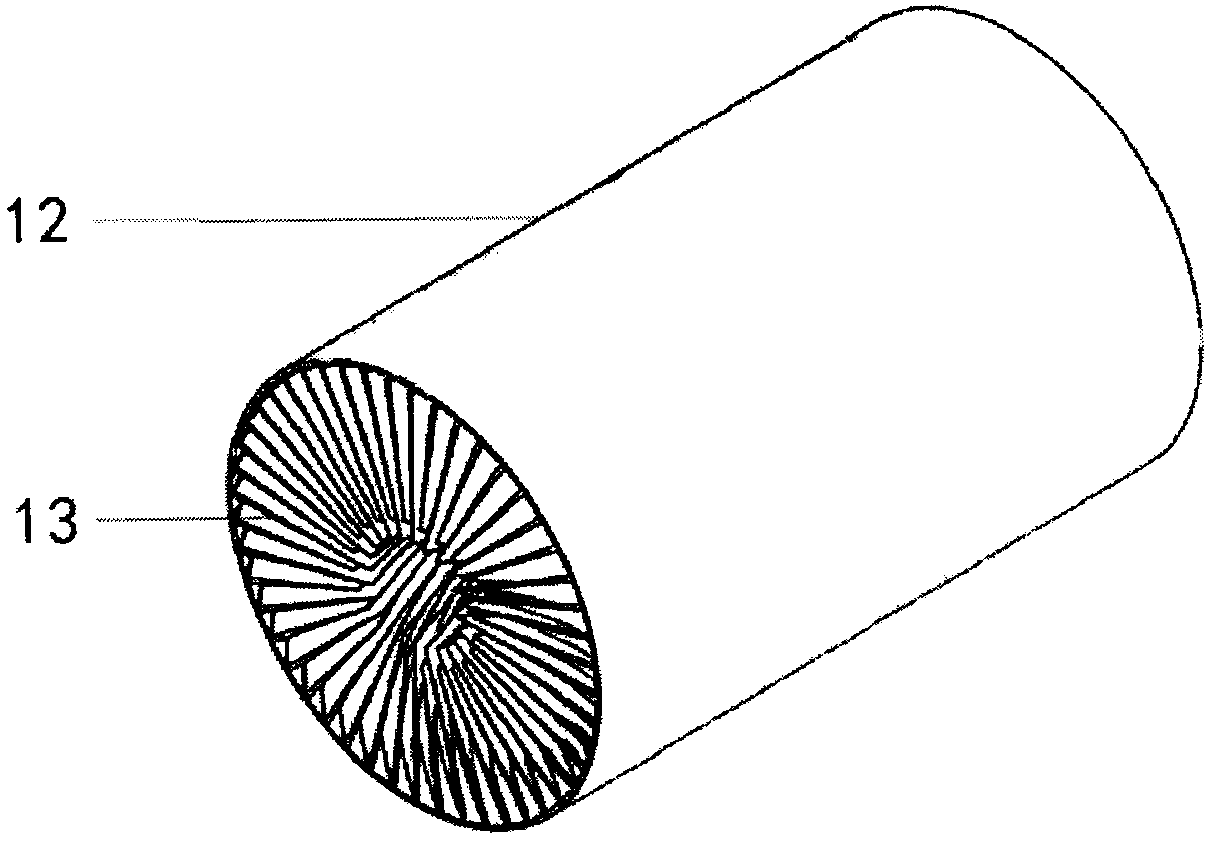

Active coke/charcoal flue gas desulphurization denitration and elemental sulfur-recovery technology and device

ActiveCN104001403AIncrease profitLow mechanical strength requirementDispersed particle separationSulfur preparation/purificationSulfurSorbent

The invention discloses an active coke / charcoal flue gas desulphurization denitration and elemental sulfur-recovery technology and device. The technology utilizes active coke / charcoal as an adsorbent and can realize synergetic removal of pollutants in flue gas in an adsorption tower, and the adsorbed active coke / charcoal are fed into a regeneration tower for heat regeneration; the regenerated active coke / charcoal is screened by a screening machine, the active coke / charcoal having large granule sizes is returned to the adsorption tower and then are subjected re-adsorption, and the active coke / charcoal having granule sizes less than 1.5mm is fed into a gasification furnace for water gas synthesis; and the water gas and SO2 obtained by heat regeneration undergo a reaction in a reduction tower to produce elemental sulfur steam, the sulfur steam from the reduction tower is fed into a condenser and then is condensed into sulfur solids, and the non-condensable gas from the top of the condenser is fed into the adsorption tower. The technology and device realize synthesis of water gas from small-granule active coke / charcoal obtained by adsorption-regeneration, realize reduction and enrichment of SO2 thereby preparing elemental sulfur, improve an active coke / charcoal utilization rate and realize high-value recovery of a sulfur resource.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI +1

Delivery and recovery sheaths for medical devices

InactiveUS20100174355A1Shorten the timeQuick exchangeStentsBlood vesselsControl systemDistal portion

Owner:ABBOTT CARDIOVASCULAR

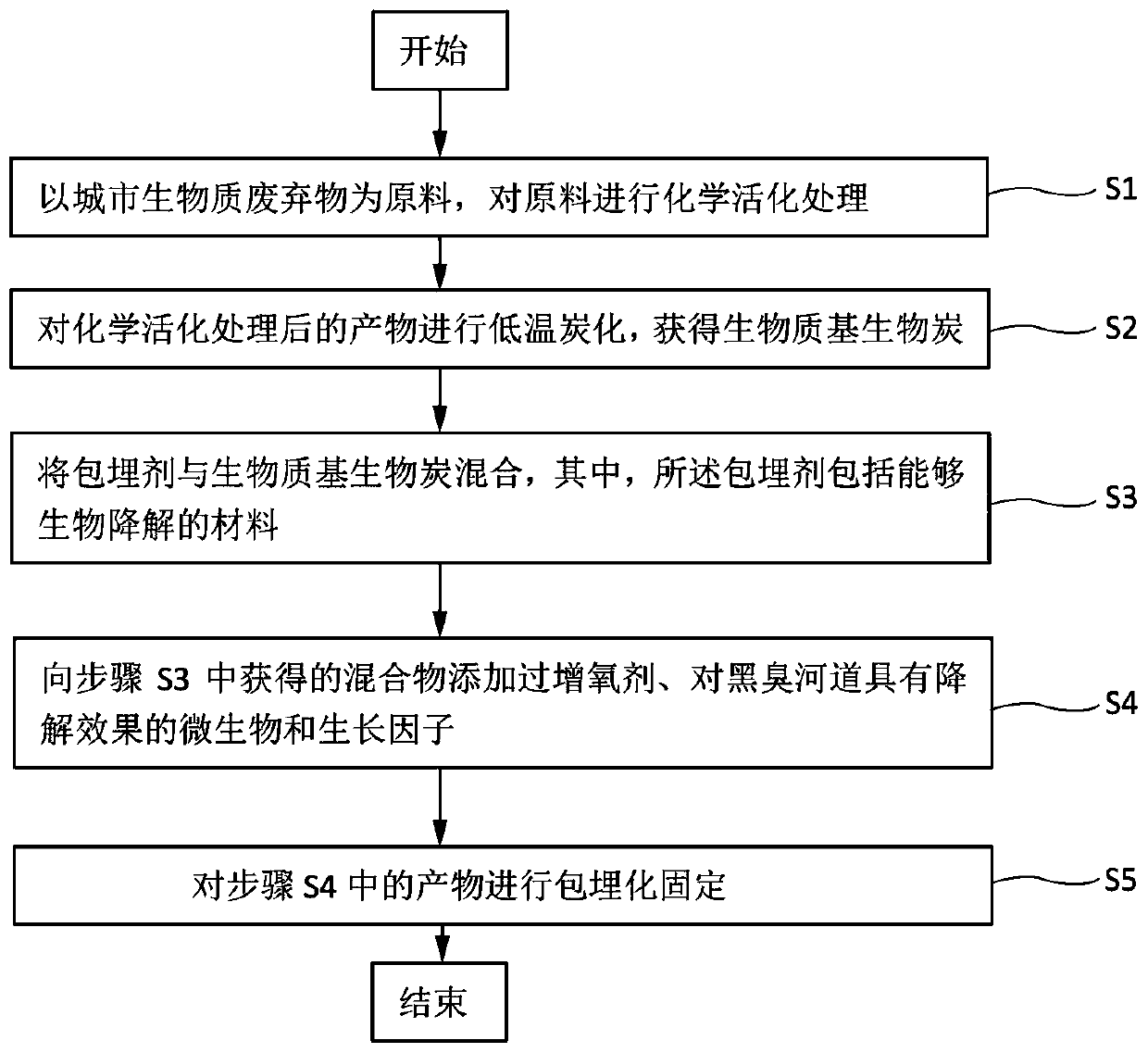

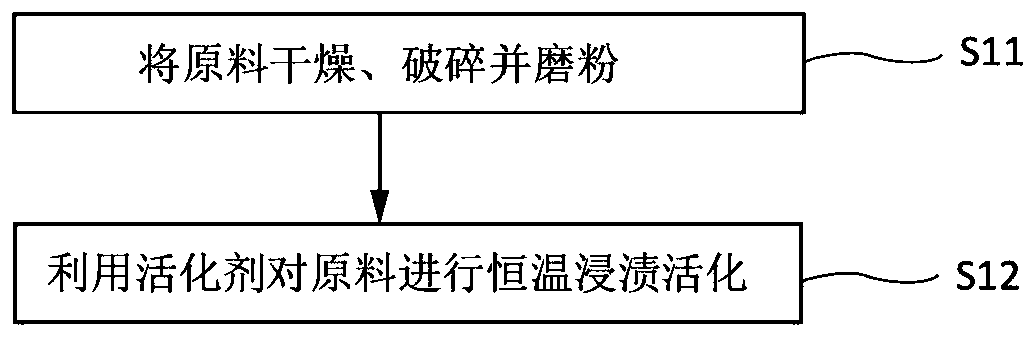

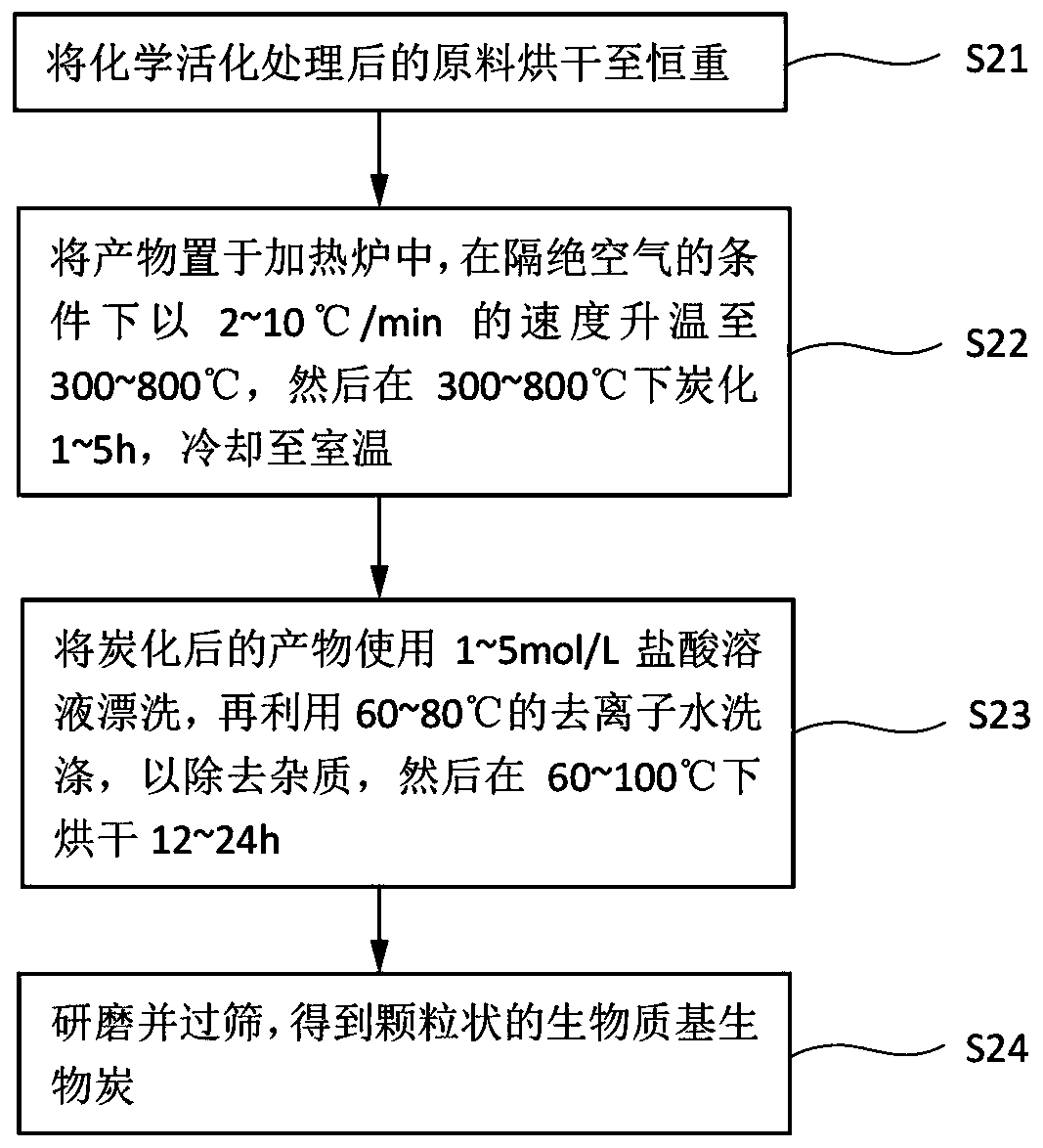

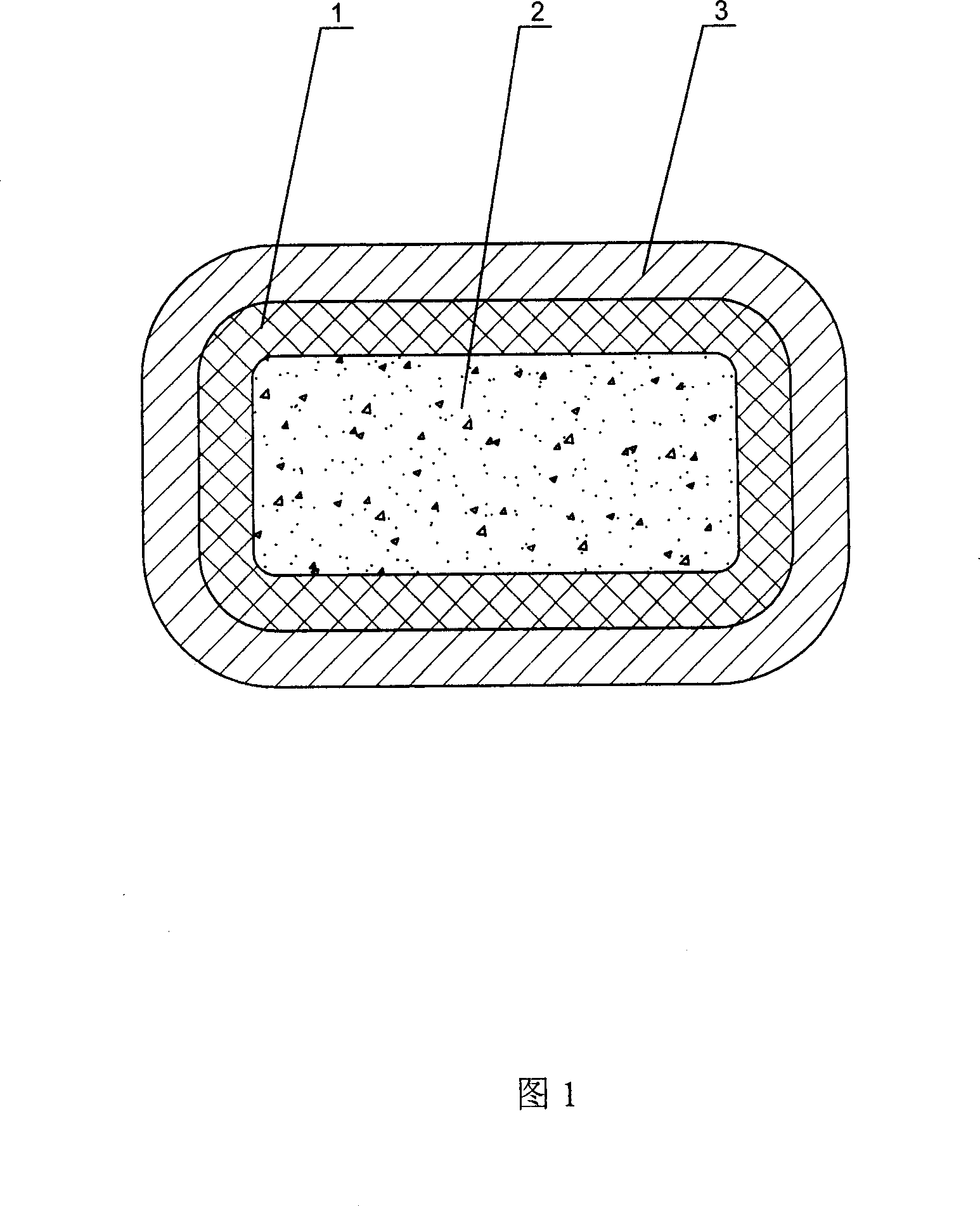

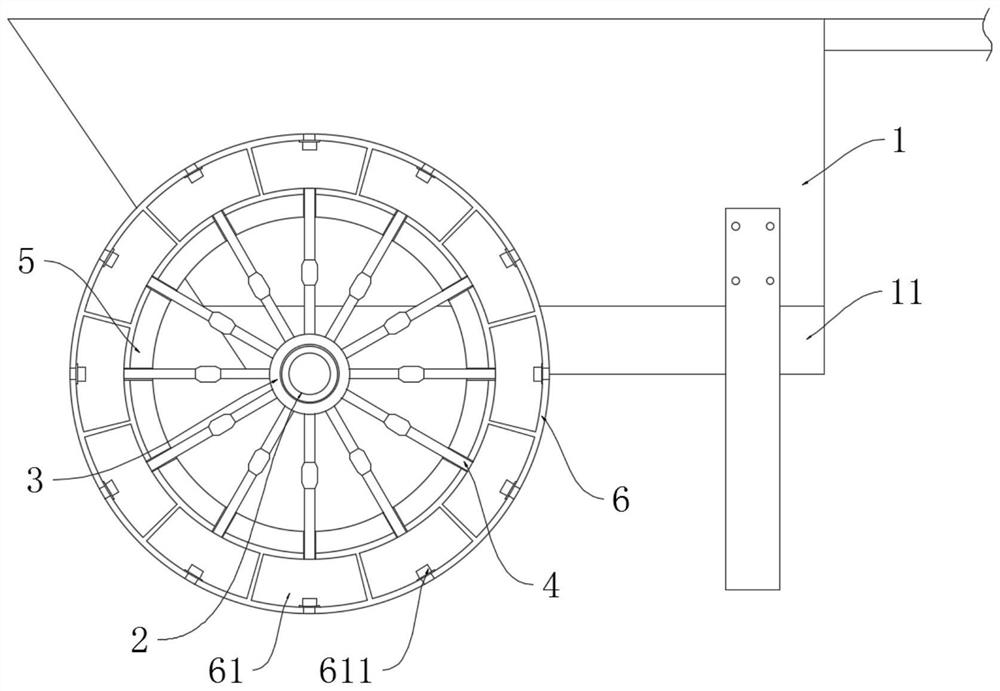

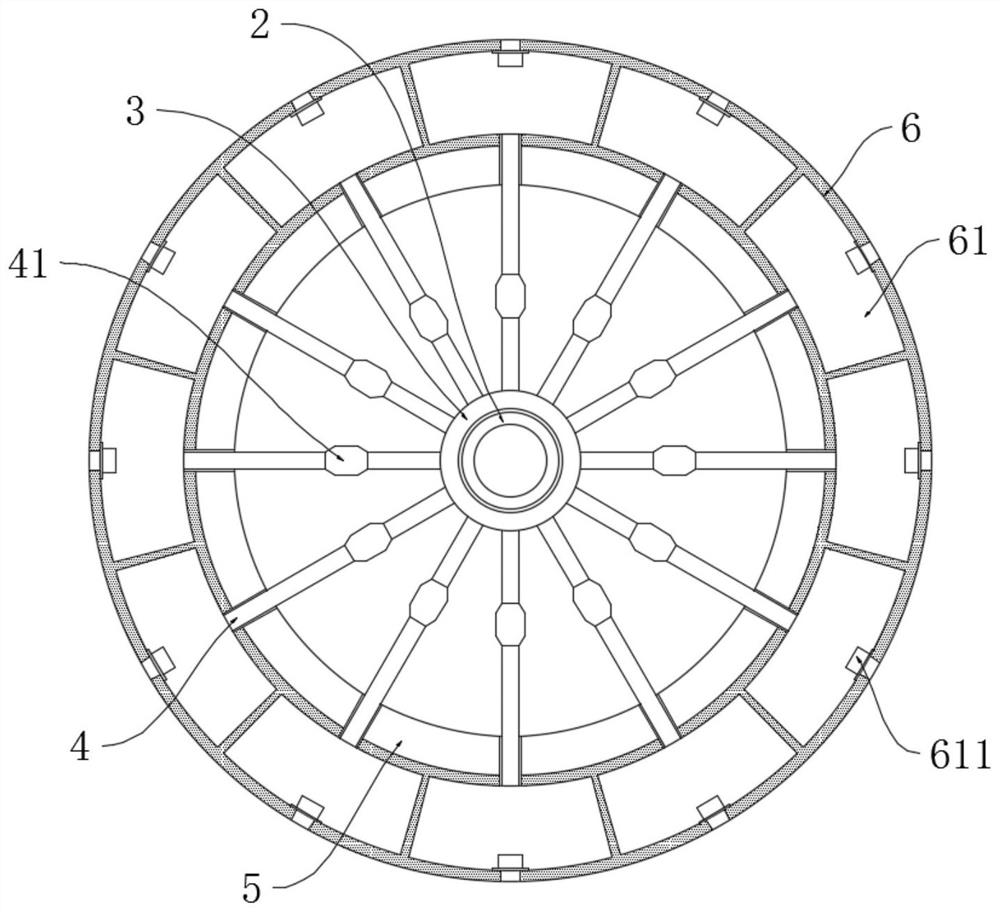

Immobilized microorganism structural body and preparation method thereof

InactiveCN109734199ALess oxygen consumptionAchieve reductionTreatment using aerobic processesSustainable biological treatmentBiomassChemistry

The invention provides an immobilized microorganism structural body and a preparation method thereof. The method comprises the following steps: S1, taking municipal biomass waste as a raw material, and chemically activating the raw material; S2, carbonizing the chemically activated product at a low temperature to obtain biomass-based biochar; S3, mixing an embedding agent with the biomass-based biochar, wherein the embedding agent comprises a biodegradable material; S4, adding an oxygenation agent, microorganisms with a degradation effect for black and smelly river channels and growth factor to the mixture obtained in step S3; and S5, embedding and immobilizing the product in step S4.

Owner:SHENZHEN HONGKONG INSTITUTION OF IND EDUCATION & RES ENVIRONMENTAL ENG TECH CO LTD

Guide wire locking mechanism for rapid exchange and other catheter systems

ActiveUS20060224176A1Avoid re-releaseHigh strengthBalloon catheterInfusion syringesMOTION LIMITATIONEngineering

A guide wire locking mechanism for a catheter system includes a motion-limiting component adapted to contact a portion of a guide wire and limit the direction of motion that the guide wire can slide therethrough. The motion-limiting component allows the guide wire to slide in one direction when placed in the locking mechanism but prevents the guide wire from moving in the opposite direction. The motion-limiting component can be made from a row of movable teeth having contact surfaces or faces which come in contact with a portion of the guide wire. The teeth are bendable to allow the guide wire to move in one direction but will tighten against the guide wire if one attempts to move the guide wire in an opposite direction. The guide wire locking mechanism can be used with a recovery sheath that can be advanced over the guide wire to collapse an expandable filtering portion mounted on a guide wire. The locking mechanism helps to maintain the recovery catheter on the collapsed filtering portion to allow both the recovery catheter and the filtering device to be simultaneously removed from the patient's vasculature, thus preventing the possibility that the recovery catheter can somehow be retracted off the filtering portion during removal.

Owner:ABBOTT CARDIOVASCULAR

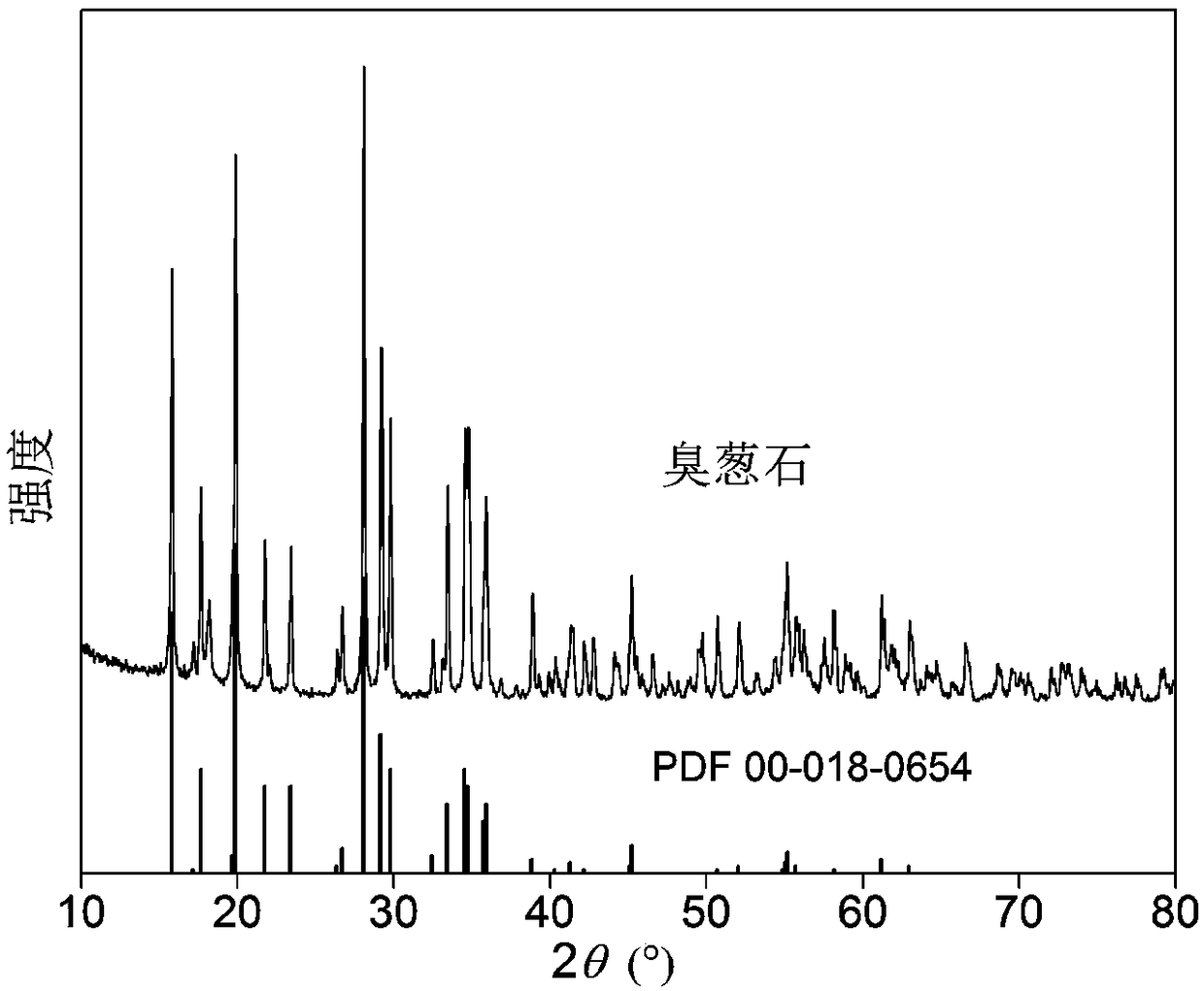

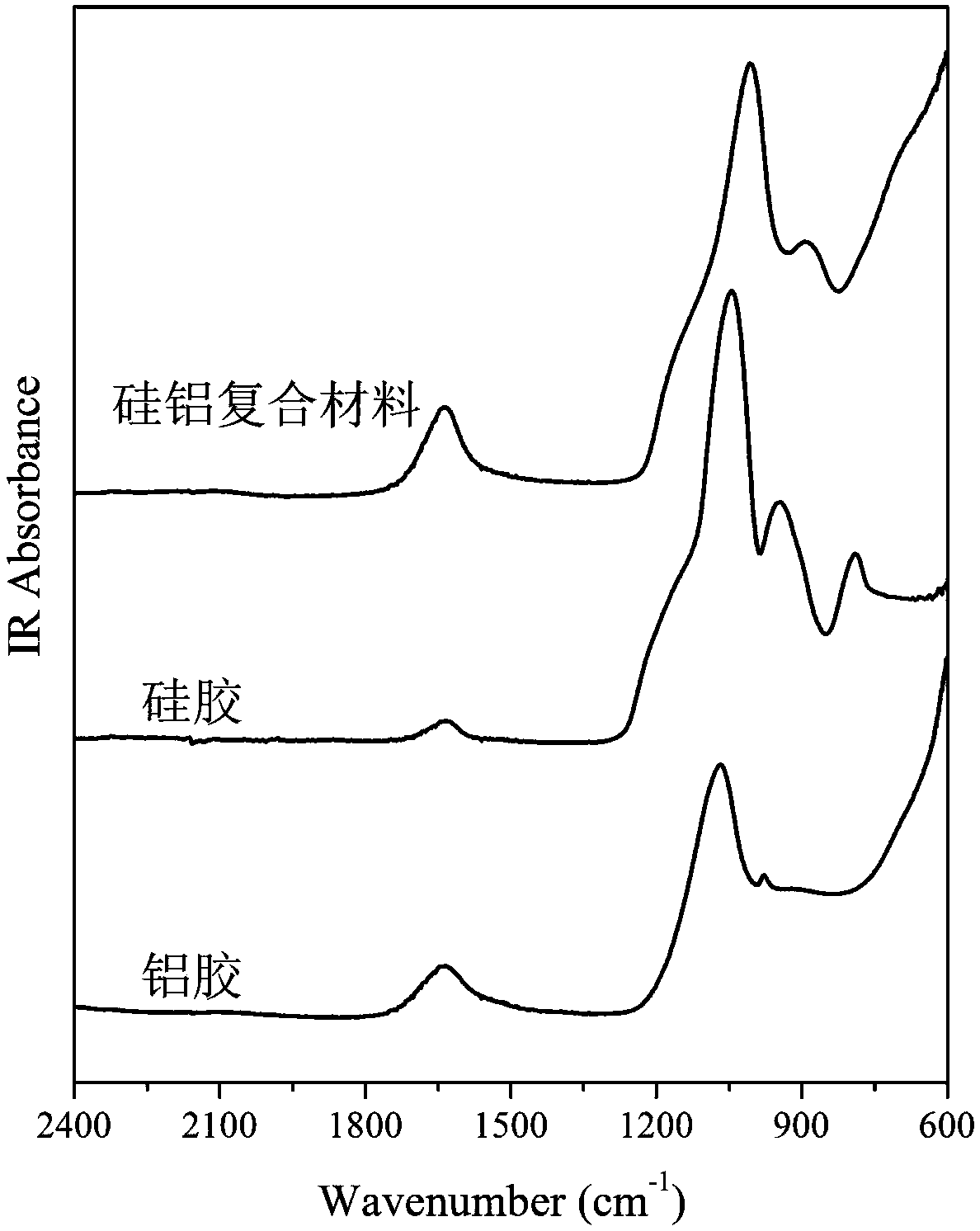

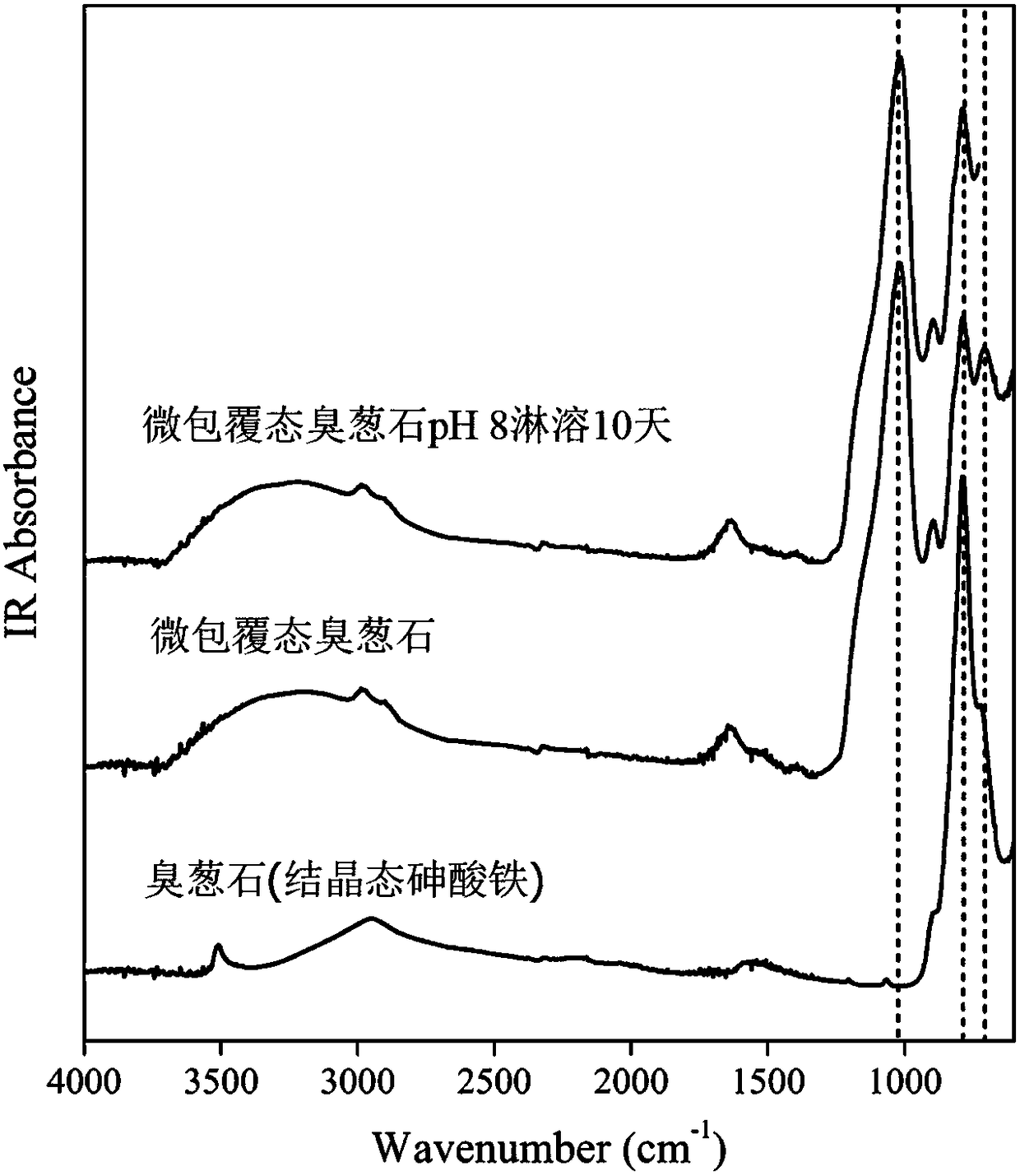

Stabilizing method of arsenic-containing waste residues

ActiveCN108188145AAvoid re-releaseAvoid secondary pollutionSolid waste disposalTransportation and packagingChemistryAluminum composites

The invention provides a stabilizing method of arsenic-containing waste residues. The stabilizing method comprises the steps that the arsenic-containing waste residues, a water soluble silicate, watersoluble aluminum salt and water are mixed and undergo a replacement reaction, wherein the pH in the replacement reaction is 2-11. The arsenic-containing waste residues, the silicate, the aluminum salt and the water are mixed under the condition of the appropriate pH and undergo the replacement reaction, and the silicate reacts with the aluminum salt to produce a silicon-aluminum composite coatingthe surfaces of the arsenic-containing waste residues, so that the arsenic-containing waste residues are isolated from the external environment, the stability of the arsenic-containing waste residuesis further improved, and arsenic is prevented from being released again. What is proven by the results of the embodiment is that with the adoption of the stabilizing method, the silicon-aluminum composite coats the surfaces of the arsenic-containing waste residues, the arsenic-containing waste residues are still prevented from further releasing the arsenic to the environment through a 10-day leaching stability test well, and secondary pollution to the environment is avoided.

Owner:SHENYANG INST OF APPLIED ECOLOGY - CHINESE ACAD OF SCI +1

Modified activated carbon for removing formaldehyde and preparation method of modified activated carbon

InactiveCN107175074AImprove adsorption capacityExtend the life cycleGas treatmentPhysical/chemical process catalystsActivated carbonTrapping

The invention discloses modified activated carbon for removing formaldehyde and a preparation method of the modified activated carbon. According to the preparation method of the modified activated carbon, 5-10 parts of ultrafine particle titanium dioxide, 3-5 parts of nano silicon dioxide, 4-6 parts of a formaldehyde trapping agent and 0.5-1 part of a dispersant are added to water at the temperature of 60-80 DEG C and stirred for 5 min, 100 parts of activated carbon and 10-20 parts of a bonding agent are added, the obtained mixture is soaked for 3-4 hours and then dried at 80-100 DEG C for 1-2 hours, and a crude sample is taken out; the crude sample is air-dried; the air-dried crude sample is sieved with a 90-mesh sieve, and a product is obtained; a photocatalyst is supported on activated carbon and catalyzes and degrades formaldehyde on the activated carbon under the illumination condition, carbon dioxide and water are produced, secondary pollution of formaldehyde is avoided, the adsorption effect of the activated carbon is enhanced, and the life cycle of the activated carbon is prolonged.

Owner:HENAN XICHAO IND CO LTD

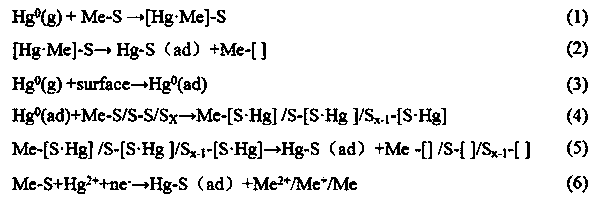

Application of metal sulfide mercury removal agent in washing removal of mercury in flue gas

PendingCN111330427AEfficient removalImprove environmental benefitsDispersed particle separationDust controlMetallic sulfide

The invention discloses an application of a metal sulfide mercury removal agent in washing removal of mercury in flue gas. The metal sulfide mercury removal agent is used as a mercury removal medium,the mercury removal agent is added into a flue gas washing device or a wet dust removal device to form a suspension, the suspension makes full contact with elemental mercury (Hg<0>) in flue gas, and mercury is converted into stable mercury sulfide, so efficient removal of the elemental mercury (Hg<0>) in the flue gas is achieved. The mercury removal agent adopted by the invention has the advantages of high mercury removal efficiency, simple synthesis method, accessible raw materials, lower cost, favorable mechanical properties, favorable acid resistance, favorable water resistance and favorable SO2 resistance, is simple in technical operation, and does not change the production process or the existing pollutant control system. Components of the mercury removal agent are similar to those ofsmelting raw materials, and the mercury removal agent obtained after mercury is recycled can be used as a metallurgical raw material, so secondary pollution is avoided, and the mercury removal agenthas wide market application prospects.

Owner:CENT SOUTH UNIV

Method and product for purifying air

InactiveCN101011641AEliminate pollution hazardsSaturation time delayLighting and heating apparatusDispersed particle separationActivated carbonFiber

The invention discloses an air purifying product and method, which comprises the following steps: adopting fiber of immersed formaldehyde eliminator to polymerize or decompose formaldehyde; using strong adsorbing material to adsorb other harmful gas. The product is composed of decomposing layer as outer layer made of fiber material and active material as inner part with strong adsorbing ability and drug liquid in the fiber to decompose and eliminate harmful gas.

Owner:陈晓鹏

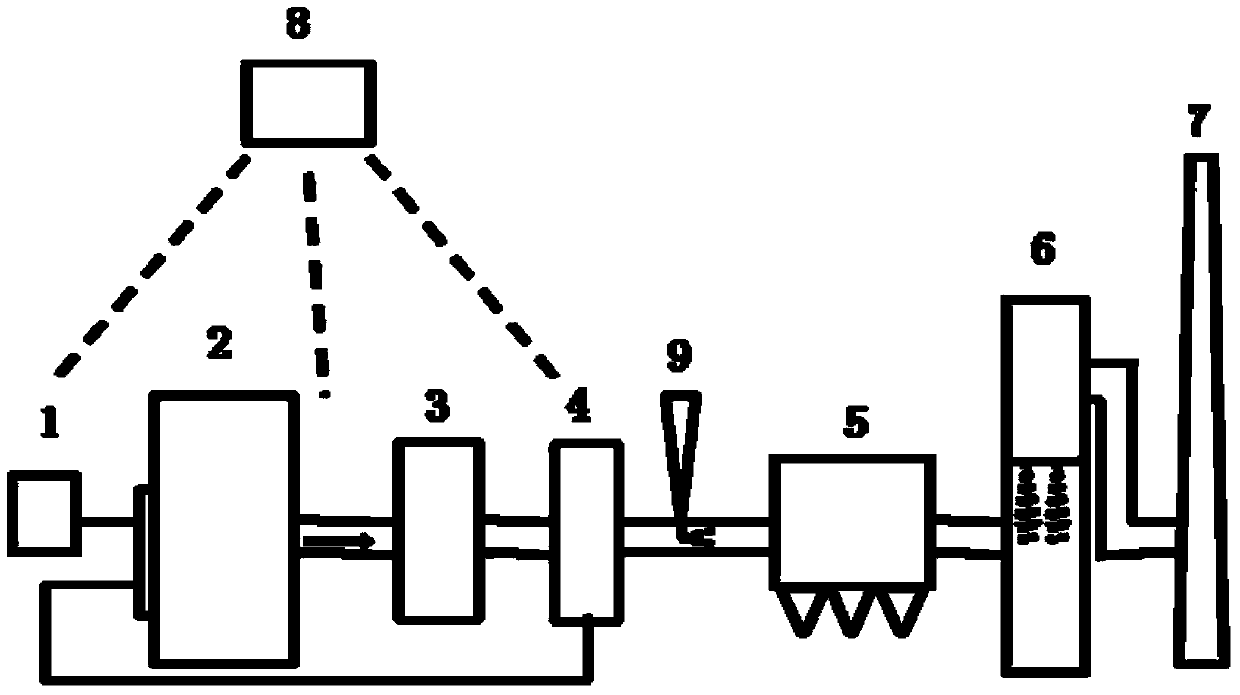

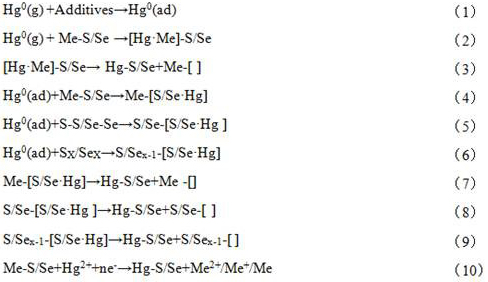

Enhanced system and method for adsorption removal of mercury in coal-fired flue gas

InactiveCN103727553AGuaranteed conversion efficiencyReduce dosageLighting and heating apparatusFlueEngineering

The invention discloses an enhanced system and method for adsorption removal of mercury in coal-fired flue gas. The system comprises an additive feeding system and an adsorbent ejection system, wherein the additive feeding system is disposed on a coal feeding system, a boiler body, a denitration device or an air preheater, and the adsorbent ejection system is disposed between the air preheater and a dedusting device. The method includes: additives are added into the coal feeding system, the boiler body, the denitration device or the air preheater through the additive feeding system, and the additives are in complex physical and chemical reactions with zero-valence mercury in a boiler chamber or high-temperature flue system to convert the zero-valence mercury into bivalent mercury which is easier to be adsorbed by adsorbent; the adsorbent is ejected into a medium-and low-temperature flue gas system between the air preheater and the dedusting device to adsorb mercury and compounds thereof to generate mercury particles; finally, mercury is captured by the dedusting device along with the adsorbent and fly ash when flue gas passes through the dedusting device, thereby removal of mercury in coal-fired flue gas is realized.

Owner:XIAN TPRI BOILER ENVIRONMENTAL PROTECTION ENG CO LTD +1

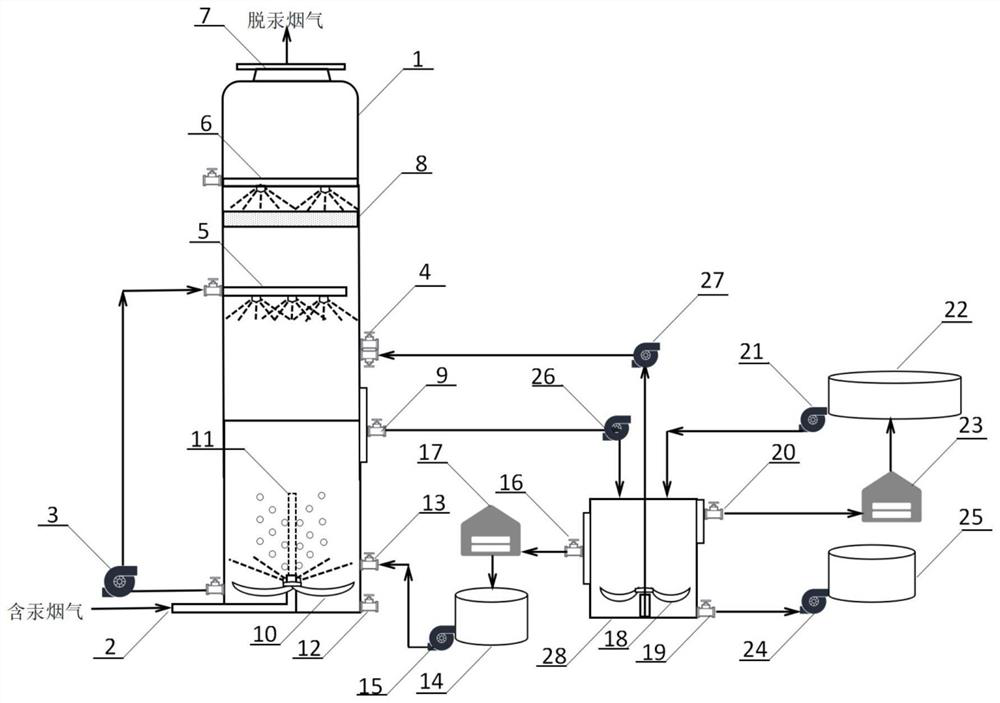

Stable suspension system for removing mercury in flue gas and recovery method of suspension system

ActiveCN112755764AImprove mercury removal efficiencyLarge capacityGas treatmentDispersed particle separationFlue gasControl system

The invention discloses a stable suspension system for removing mercury in flue gas and a recovery method of the suspension system. Metal sulfur, a selenide mercury removal agent and an additive are pretreated to form a stable suspension, the mercury-containing flue gas is in contact with the suspension, gaseous mercury (Hg0) is converted into stable mercuric sulfide or mercury selenide, and efficient removal of gaseous mercury in the flue gas is achieved. According to the method, existing pollutant control systems in various industries can be utilized, and the cost is low; the suspension system is simple to recover and separate and can be recycled; mercury can be recycled as a product; and the market prospect is wide.

Owner:CENT SOUTH UNIV

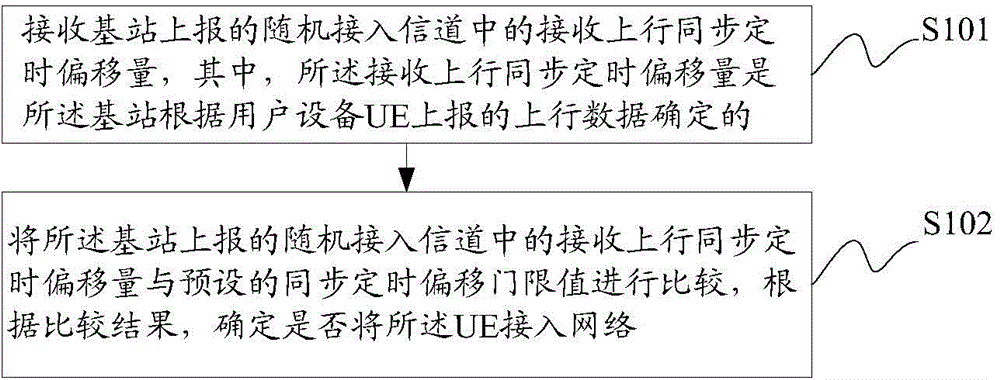

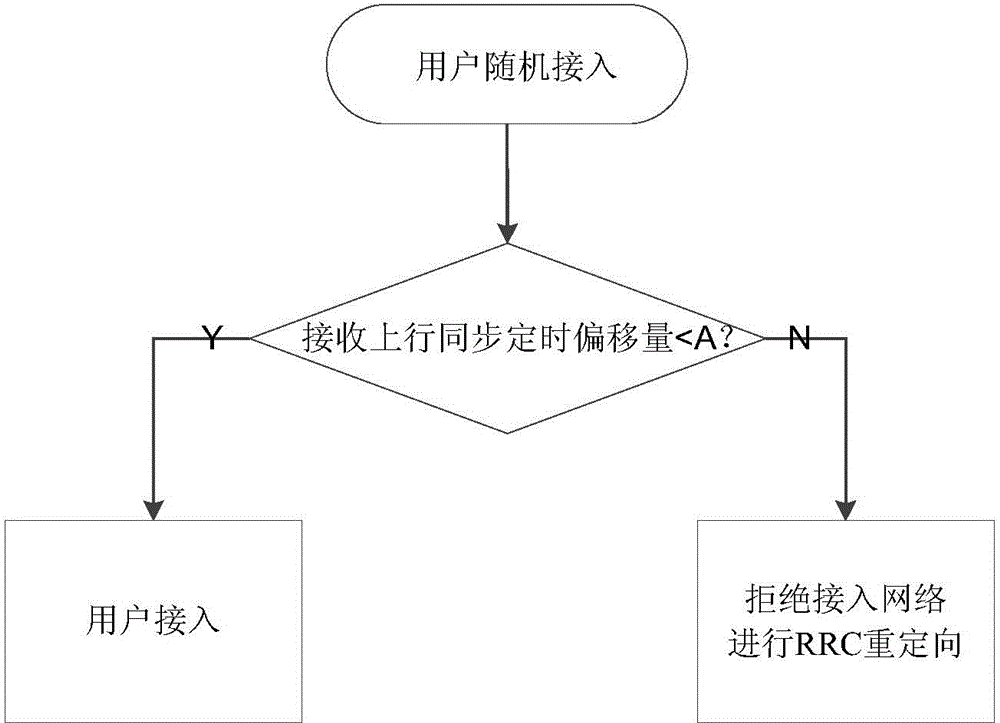

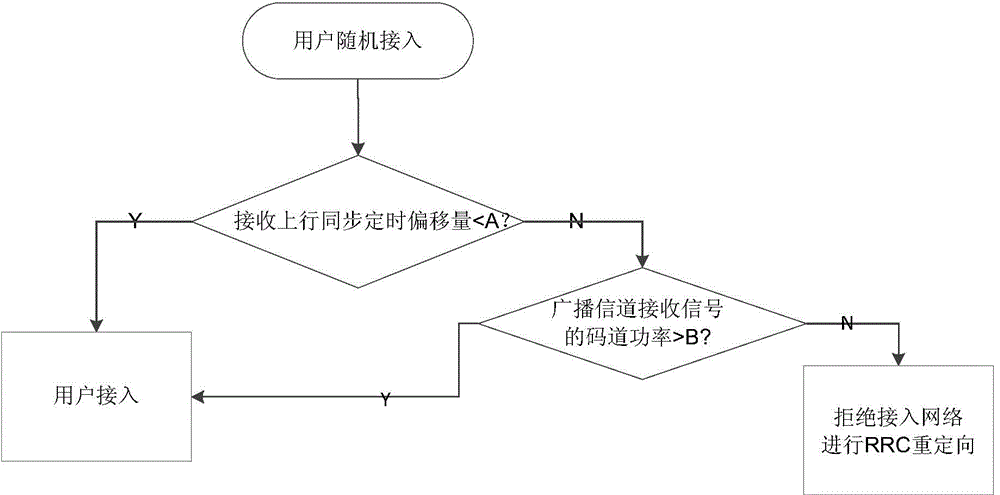

Method and device for controlling access of user equipment

ActiveCN104159270AAvoid re-releaseReduce hidden dangers of national information securityAssess restrictionRandom-access channelInformation security

The invention discloses a method and device for controlling the access of user equipment, is used for realizing the control on the state whether all the user equipment can access to a network or not, and can reduce national information security hazards caused by the fact that user equipment failing at reporting time advance access to a network illegally overseas. The method comprises the following steps: firstly, receiving the reception uplink synchronization timing offset in an RACH (Random Access Channel) reported by a base station, wherein the reception uplink synchronization timing offset is determined through the uplink data reported by the base station according to UE; secondly, comparing the reception uplink synchronization timing offset in the RACH reported by the base station with a preset synchronization timing offset threshold value, and determining whether the UE accesses to the network or not according to the comparative result.

Owner:DATANG MOBILE COMM EQUIP CO LTD

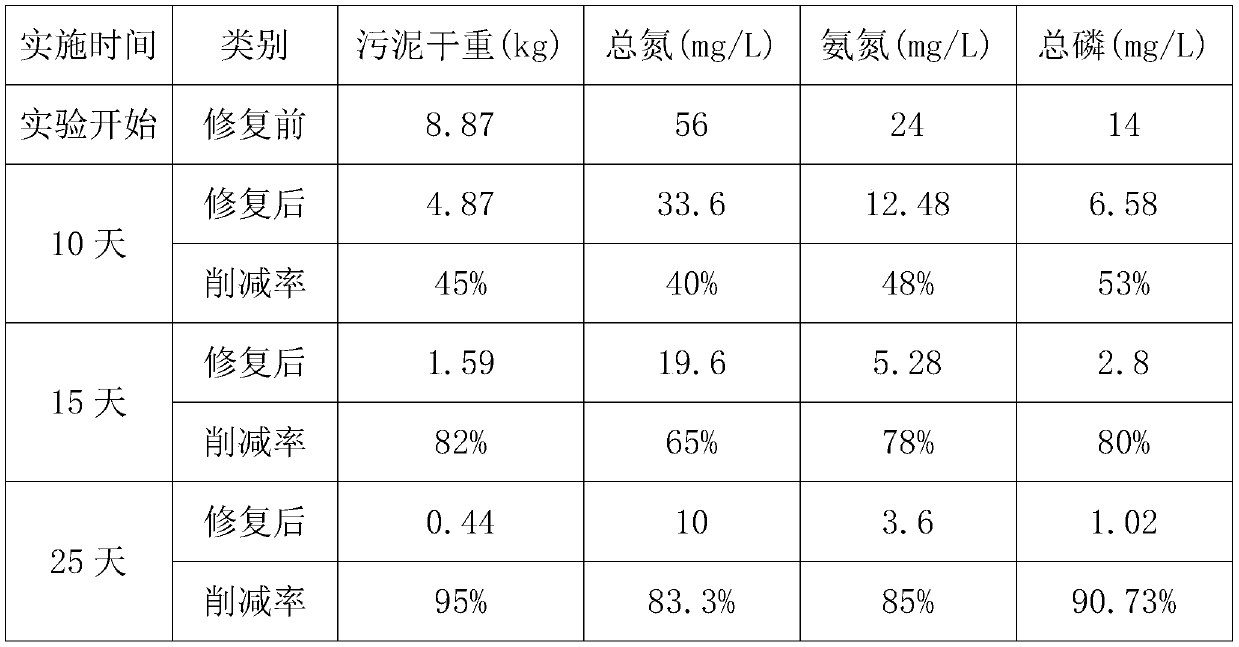

In-situ repairing material of bottom mud of black and odorous water body and preparation method of in-situ repairing material

InactiveCN110627335AGood phosphorus and nitrogen removal effectSpeed up decompositionWater treatment compoundsSpecific water treatment objectivesDecompositionMaterial resources

The invention belongs to the technical field of sewage treatment materials and preparation thereof and discloses an in-situ repairing material of bottom mud of a black and odorous water body and a preparation method of the in-situ repairing material. The material is prepared from various raw materials which have good nitrogen and phosphorus removal effects, very good slow release functions and inaddition are rich in source. By improving living environments of microorganisms of the bottom mud, increasing the decomposition speeds of the microorganisms upon organic matters in the bottom mud andimproving the nitrogen and phosphorus removal effects, amount reduction of the bottom mud can be promoted; and in addition, phosphorus in the bottom mud can be effectively immobilized through phosphorus immobilization components in the various raw materials, the phosphorus can be prevented from being released into the water body again, and effects that endogenous pollution is effectively reduced,degradation of pollutants of the bottom mud is accelerated, the amount of sludge of the black and odorous water body is reduced, situations of the water body areimproved, and the treatment effects arelong-lasting can be achieved. The preparation method is simple and rapid in operation process, small in number of equipment for operation, low in requirement on operators, low in cost and applicableto industrial production and popularization, and consumption of labor resources, material resources and economic resources can be effectively reduced.

Owner:BEIJING ZHONGKE AOSHUI ENVIRONMENTAL PROTECTION ENG TECH

Liquid diatom ooze functional coating material

InactiveCN108707349AWith decompositionGuaranteed stabilityAntifouling/underwater paintsAlkali metal silicate coatingsCelluloseWater based

The invention discloses a liquid diatom ooze functional coating material, and relates to the technical field of decorative coating. The liquid diatom ooze functional coating material comprises, by weight, 15-20 parts of diatom ooze, 3-5 parts of nanometer titanium dioxide, 20-25 parts of organically modified organic cementitious materials, 0.2-0.3 part of wetting agents, 0.4-0.6 part of dispersingagents, 0.5-1 part of thickening agents, 1-2 parts of propylene glycol, 0.1-0.3 part of defoaming agents, 0.1-0.2 part of bactericides, 0.03-0.05 part of celluloses, 0.1-0.2 part of leveling agents,10-20 parts of titanium dioxide powder, 10-15 parts of kaolin, 5-10 parts of heavy calcium carbonate, 0-5 parts of wollastonite powder and the balance purified water. Sand filtration, ultra-filtrationand reverse osmosis filtration are carried out on water to obtain the purified water with a TDS (total dissolved solids) value lower than or equal to 50; additives among raw materials are added intothe purified water and are uniformly dispersed and stirred to obtain first mixtures; the diatom ooze, the nanometer titanium dioxide and fillers among the raw materials are added into the first mixtures and are uniformly stirred to obtain second mixtures; the organically modified organic cementitious materials are added into the second mixtures and are sufficiently stirred to obtain the liquid diatom ooze functional coating material. The liquid diatom ooze functional coating material has the advantages that the hardness and the stability of paint films formed by the water-based diatom ooze canbe guaranteed, the water-based diatom ooze is good in gas permeability, and the adsorption of the water-based diatom ooze can be guaranteed.

Owner:童彬原

Water-based diatom ooze functional coating material and preparation method thereof

InactiveCN108822585AHigh purification and constructionGuaranteed stabilityCoatingsTriple superphosphateSilica fume

The invention discloses a water-based diatom ooze functional coating material and a preparation method thereof, and relates to the technical field of decorative coatings. The device is composed of thefollowing raw materials in parts by weight: 15-20 parts of diatomaceous earth, 20-25 parts of organic modified inorganic cementing material, 3-5 parts of nano titanium dioxide, 10-20 parts of titanium dioxide, 10-15 parts of kaolin, 5-10 parts of triple superphosphate, 0-5 parts of talc powder, 0-5 parts of silica fume, 0.2-0.3 parts of a wetting agent, 0.4-0.6 part of a dispersing agent, 0.5-1 part of a thickening agent, 1-2 parts of propylene glycol, 0.1-0.3 part of a defoaming agent, 0.1-0.2 part of bactericide, 0.03-0.05 part of cellulose, 0.1-0.2 part of a levelling agent and 20-30 partsof purified water. The preparation method comprises the following steps: adding additives in the raw materials into purified water, and dispersing and stirring uniformly; adding the diatomaceous earth, the nano titanium dioxide and the filler in the raw materials, and uniformly stirring; adding the organic modified inorganic cementing material, and fully stirring to obtain the water-based diatomooze functional coating material. According to the method, the hardness and the stability of the paint film of the water-based diatom ooze are guaranteed, meanwhile, the water-based diatom ooze is endowed with good air permeability, and the adsorbability of the water-based diatom ooze is guaranteed.

Owner:童彬原

Flying dust prevention cart for constructional engineering

ActiveCN112046561ARealize the function of automatic dust reduction and dust removalAvoid affecting the construction environmentWith multiple inflatable chambersHand carts with one axisMarine engineeringDust control

The invention discloses a flying dust prevention cart for constructional engineering. The flying dust prevention cart comprises a cart hopper, a dust collecting box is installed on the lower bottom face of the cart hopper, a hollow shaft is fixedly installed on the lower bottom face of the dust collecting box, two dust guiding bearings are symmetrically installed at the two ends of the hollow shaft, a plurality of supporting pipes are annularly and equidistantly installed on the outer sides of the dust guiding bearings, a steel ring is jointly installed at the ends, away from the dust guide bearings, of the multiple supporting pipes, and an airbag tire is installed on the outer side of the steel ring. The airbag tire is extruded and released by movement of the cart to form air suction andair exhaust, dust on a moving path is sucked into airbag cavities through air suction of a one-way nozzle valve, the dust in the airbag cavities is discharged into the hollow shaft and the dust collecting box through the supporting pipes and the dust guiding bearings, the dust falling and dust removal functions are achieved, the structure is simple, flying dust is avoided, and the construction environment is improved.

Owner:天业建设集团有限公司

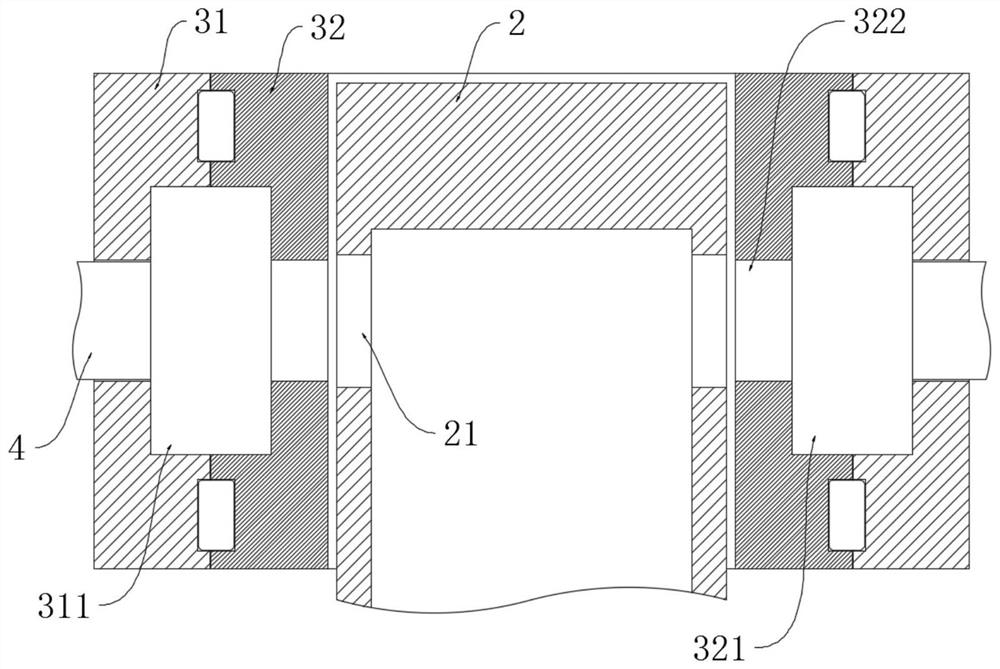

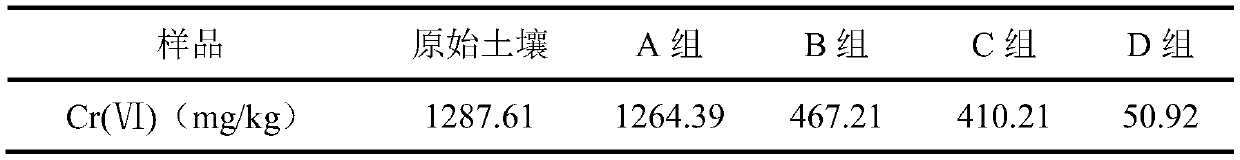

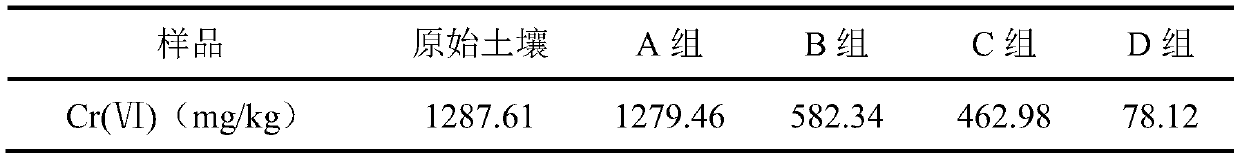

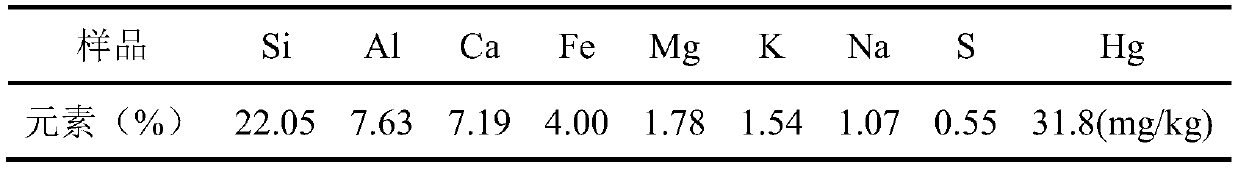

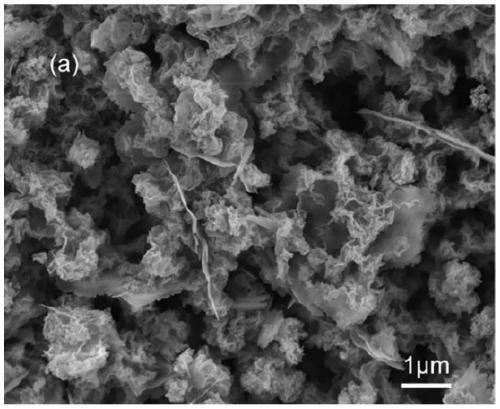

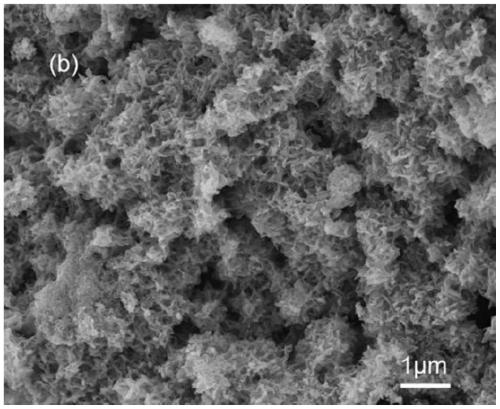

Method and reagent for repairing mercury and chromium deep contaminated soil by cooperation of anaerobic sulfate reducing bacteria and iron-based material

ActiveCN110484275AReduced bioavailabilityEfficient repairContaminated soil reclamationOrganic fertilisersSulfate-reducing bacteriaSilicate minerals

The invention discloses a method and reagent for repairing mercury and chromium deep contaminated soil through cooperation of anaerobic sulfate reducing bacteria and an iron-based material. The reagent for repairing the mercury and chromium contaminated soil comprises the iron-based material and anaerobic sulfate reducing bacterial liquid. The iron-based material is obtained by reacting iron-containing silicate minerals with oxalic acid in an aqueous medium. The reagent is applied to mercury (II) and chromium (VI) deep contaminated soil, stabilization of mercury (II) and Cr (VI) is achieved atthe same time, the overall remediation efficiency and range can be effectively improved, the cost is low, operation is easy, secondary pollution to the soil is avoided, and therefore the reagent andthe method have wide application prospects.

Owner:CENT SOUTH UNIV

Method for restoring mercury pollution through biochemical joint

ActiveCN108435768APromote absorptionImprove efficiencyContaminated soil reclamationPlant rootsEconomic benefits

The invention discloses a method for restoring mercury pollution through biochemical joint. The method comprises the following steps that 1, the radix morindae officinalis seeds are sown in the soil polluted by the mercury to be repaired; 2, the soil conditioner is fully and uniformly mixed; step 3, the soil conditioner which is uniformly mixed is applied to soil around the root of the euphorbia pekinensis; and 4, the radix morindae officinalis are harvested in the ripening stage of the euphorbia pekinensis. The method has the advantages that the content of mercury in the soil can be effectively reduced, the plant root system is promoted to absorb mercury from the soil and transfer the mercury to the overground part of the plant, the overall repair efficiency and range are effectively improved, the cost is low, the operation is simple, the material selection is convenient, no secondary damage is caused to the soil, and potential economic benefits can be brought.

Owner:HUNAN JINLV ENVIRONMENTAL PROTECTION CO LTD +1

Efficient long-lasting formaldehyde removal diatom ooze and preparation method thereof

InactiveCN110590227ASuper high specific surface areaIncrease contact area and contact timeManganese oxideLong lasting

The invention discloses efficient long-lasting formaldehyde removal diatom ooze and a preparation method thereof. The diatom ooze disclosed by the invention has the advantages of being high in security, excellent in formaldehyde removal effect, small in environment condition dependency and stable and lasting in formaldehyde removal performance. The preparation method of the efficient long-lastingformaldehyde removal diatom ooze, which is disclosed by the invention, comprises steps that kieselguhr modification is firstly performed, manganese oxide is uniformly supported by the surface of the kieselguhr in situ, and then rich efficient lasting formaldehyde removal reaction sites are provided for the diatom ooze; and secondly, a calcium material, a mineral fiber, a thickening agent and the like are added to further improve the strength, viscosity and protection performance of the diatom ooze. The preparation method is simple and environment-friendly and applicable to large-scale use andindustrial production.

Owner:SHENZHEN CITY THROUGH SCI & TECH OF NEW ENERGY CO LTD

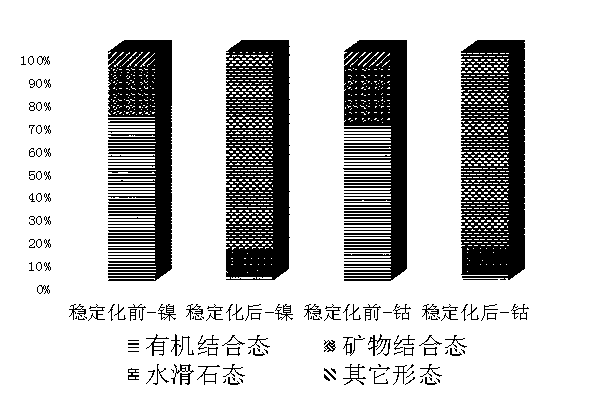

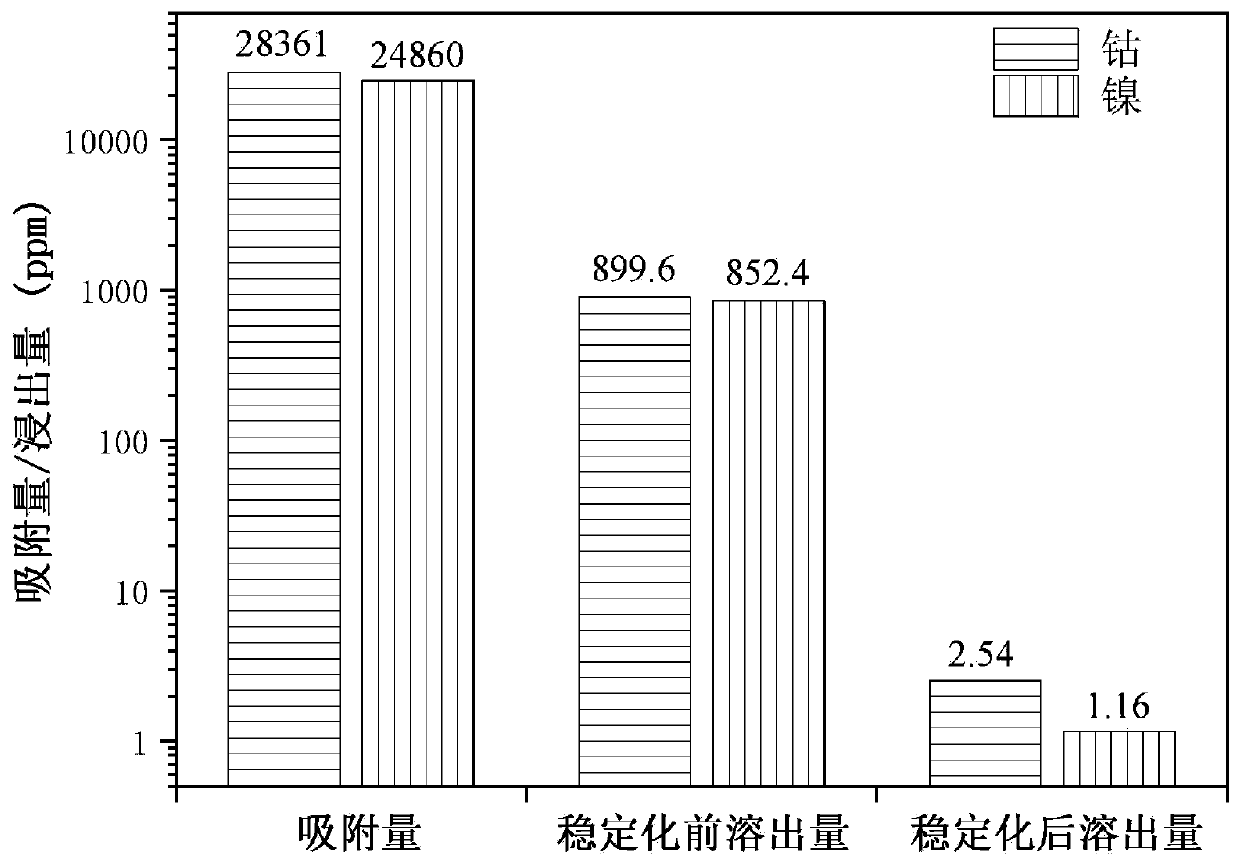

Industrial wastewater remediation material and application thereof, and treatment method of industrial wastewater containing cobalt-nickel divalent metal cations

PendingCN111558361AEasy to changeReduce doseOther chemical processesWater contaminantsIndustrial waste waterDivalent metal

The invention provides an industrial wastewater remediation material and application thereof, and a treatment method of industrial wastewater containing cobalt-nickel divalent metal cations, and belongs to the technical field of cationic heavy metal polluted water remediation. A component A in the industrial wastewater remediation material can adsorb metal ions in industrial wastewater and can also adsorb aluminum or iron ions in a component B and improve the concentration of local metal ions, meanwhile, under the pH condition provided by a component C, the conversion from the metal ions to ahydrotalcite-like mineral phase can be accelerated, and the three components are jointly used as components of the remediation material and can achieve a good synergistic effect. After the industrialwastewater remediation material is used for adsorbing heavy metal ions in industrial wastewater, the remediation material after adsorption is subjected to stabilizing treatment, heavy metal can be adsorbed for a long time to form stable hydrotalcite minerals, environmental changes can be well resisted, secondary release of the metal ions is avoided, and the problem of secondary pollution by the heavy metal is effectively avoided.

Owner:INST OF SOIL SCI CHINESE ACAD OF SCI

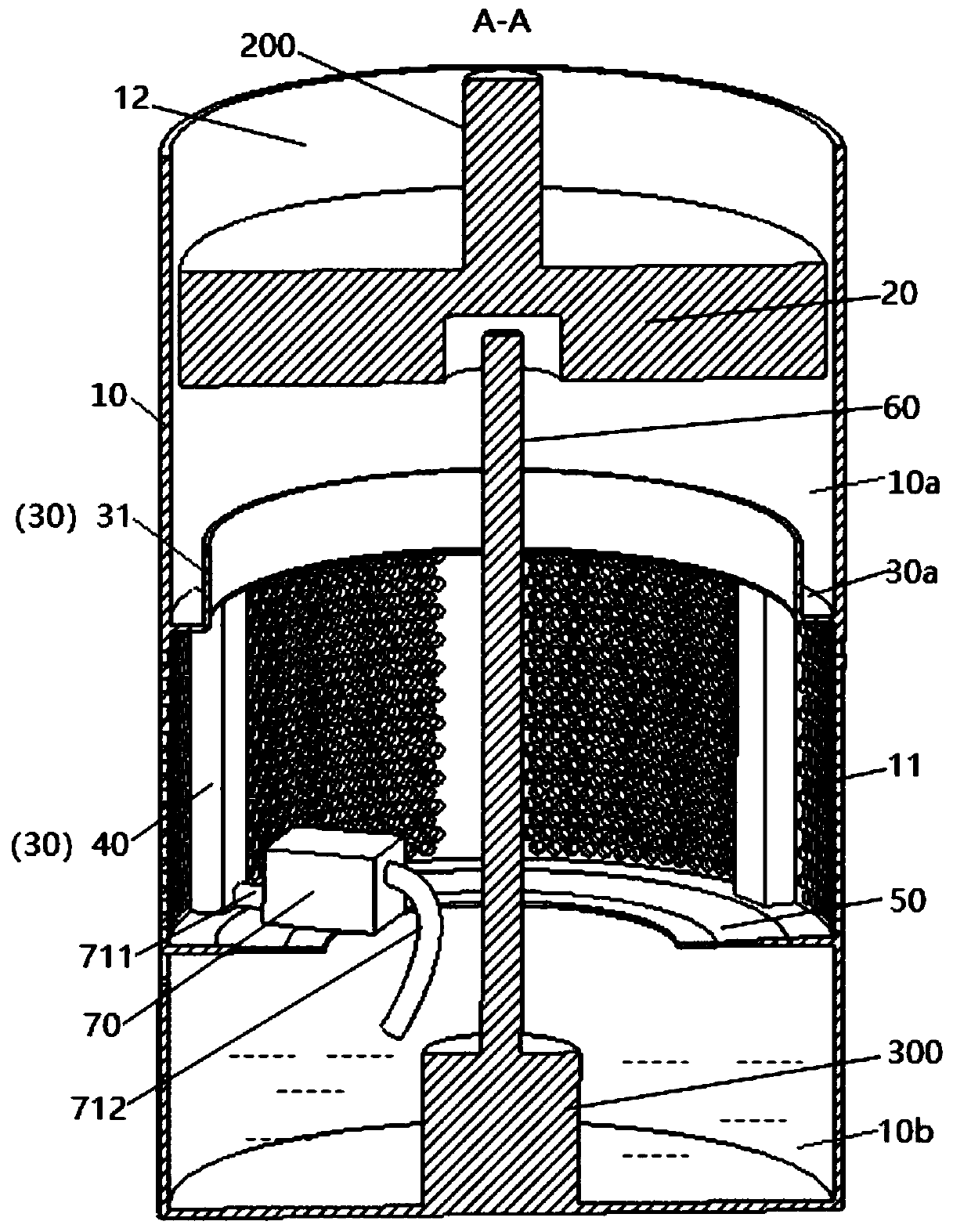

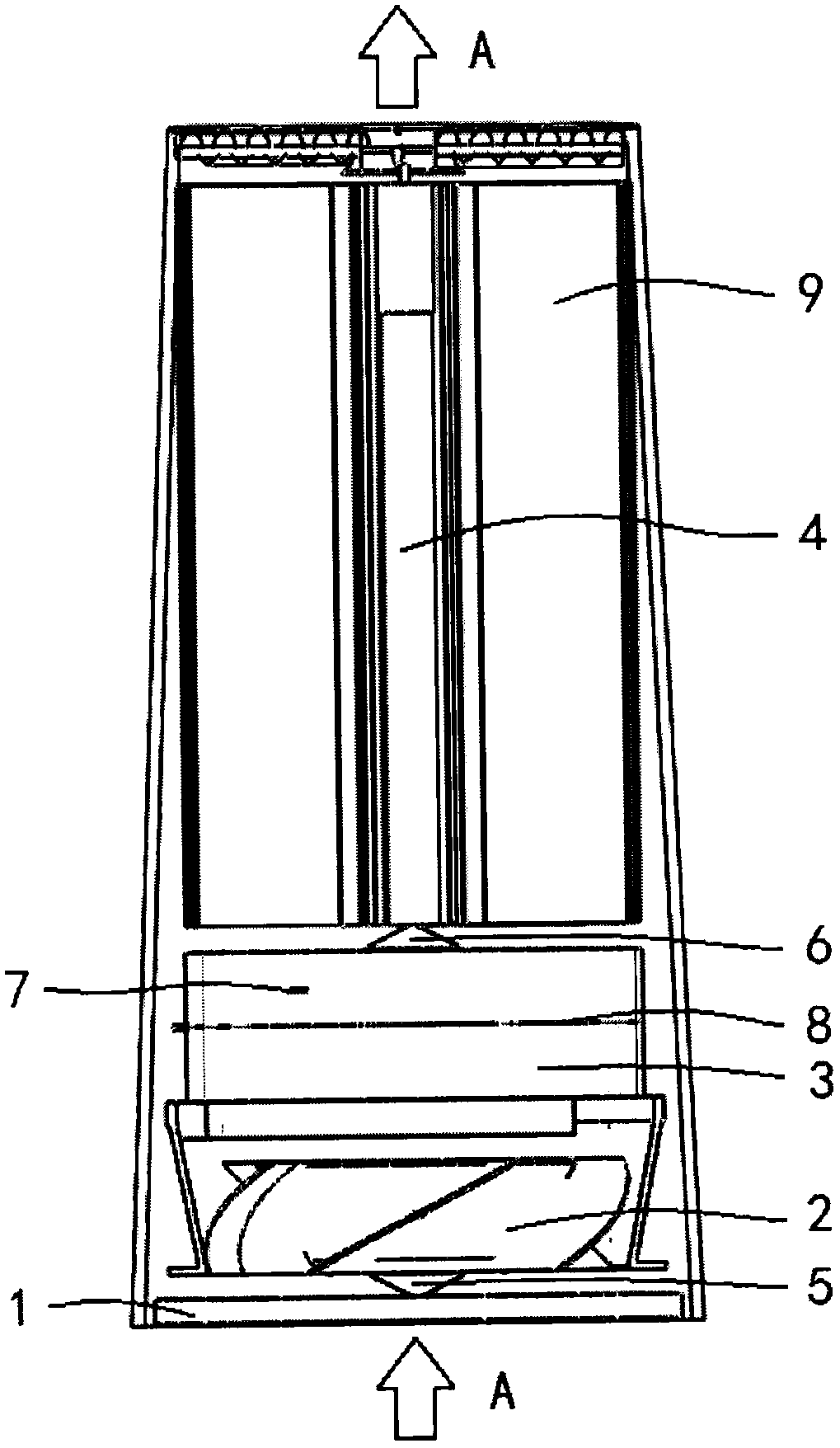

Air purification device and air purifier with same

ActiveCN111318112AImprove purification efficiencyAvoid re-releaseCombination devicesGas treatmentWater storageAir purifiers

The invention discloses an air purification device and an air purifier with the same. The air purification device comprises a shell, wherein the shell is provided with an air inlet and an air outlet,the air inlet is located in the side wall of the shell, the shell defines a rotating cavity communicated with the air inlet and the air outlet, and a water storage cavity is defined below the rotatingcavity; a purification assembly, which is rotatably arranged in the rotating cavity; a water distribution assembly, which guides water in the water storage cavity to flow upwards and distributes water into the purification assembly; and an electrolysis device, which is arranged in the shell so as to purify the liquid in the shell. After water absorbs organic matters such as formaldehyde in the air, the organic matters such as formaldehyde in the water can be removed through electrolysis, the water is prevented from being released into the air again in the cyclic utilization process, the purification efficiency of the organic matters such as formaldehyde in the air is improved, the replacement frequency is reduced, and the maintenance cost is low.

Owner:GUANGDONG MIDEA WHITE HOME APPLIANCE TECH INNOVATION CENT CO LTD +1

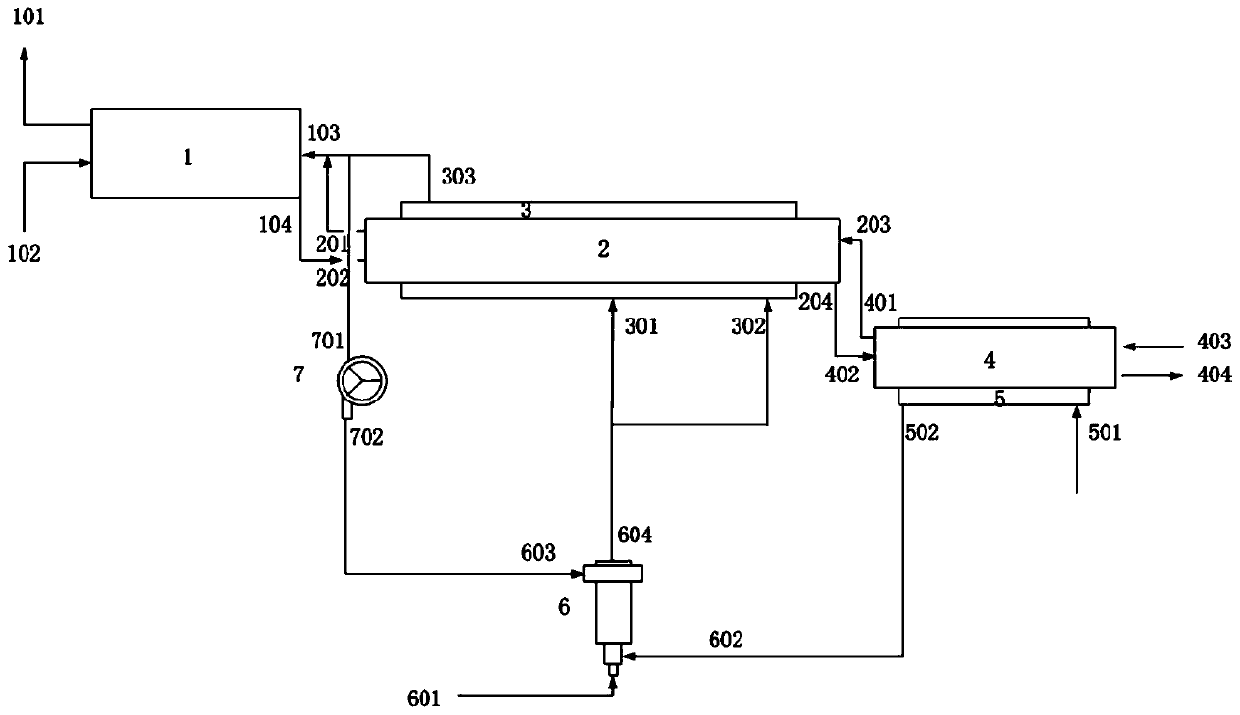

A process and device for activated coke/carbon flue gas desulfurization and denitrification and recovery of elemental sulfur

ActiveCN104001403BIncrease profitLow mechanical strength requirementDispersed particle separationSulfur preparation/purificationSorbentFlue gas

The invention discloses an active coke / charcoal flue gas desulphurization denitration and elemental sulfur-recovery technology and device. The technology utilizes active coke / charcoal as an adsorbent and can realize synergetic removal of pollutants in flue gas in an adsorption tower, and the adsorbed active coke / charcoal are fed into a regeneration tower for heat regeneration; the regenerated active coke / charcoal is screened by a screening machine, the active coke / charcoal having large granule sizes is returned to the adsorption tower and then are subjected re-adsorption, and the active coke / charcoal having granule sizes less than 1.5mm is fed into a gasification furnace for water gas synthesis; and the water gas and SO2 obtained by heat regeneration undergo a reaction in a reduction tower to produce elemental sulfur steam, the sulfur steam from the reduction tower is fed into a condenser and then is condensed into sulfur solids, and the non-condensable gas from the top of the condenser is fed into the adsorption tower. The technology and device realize synthesis of water gas from small-granule active coke / charcoal obtained by adsorption-regeneration, realize reduction and enrichment of SO2 thereby preparing elemental sulfur, improve an active coke / charcoal utilization rate and realize high-value recovery of a sulfur resource.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI +1

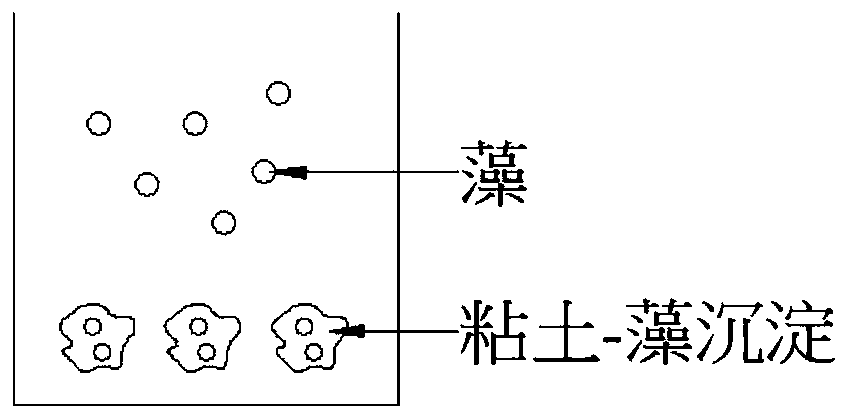

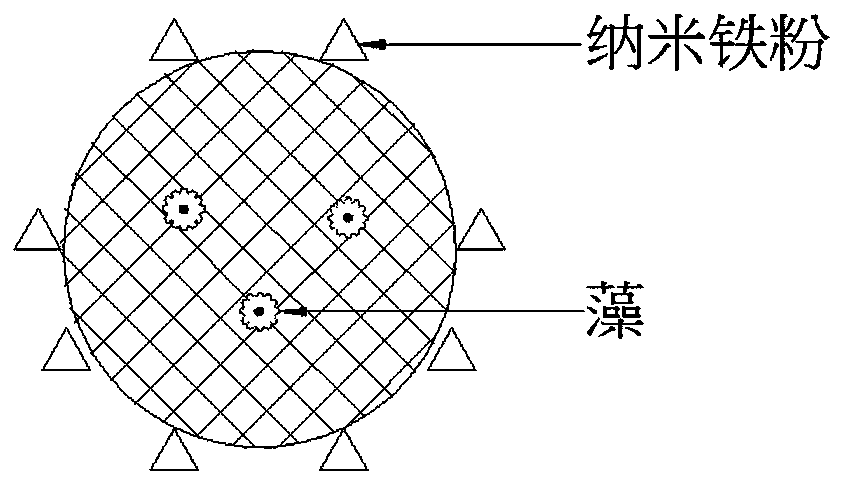

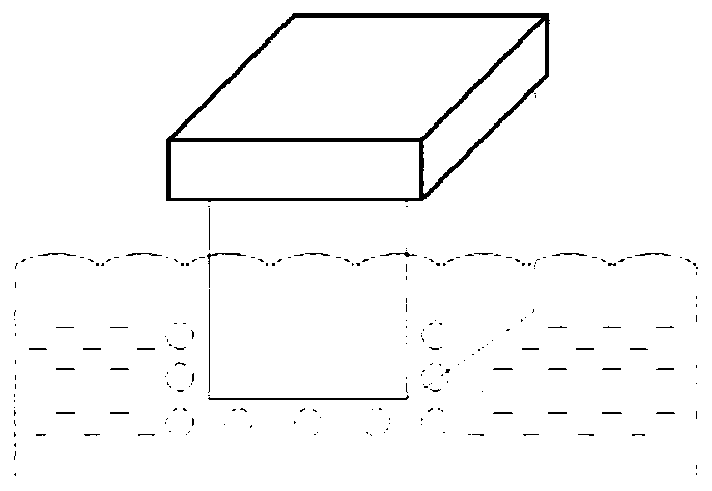

Preparation method of modified clay and application method of modified clay in directional recovery of microalgae

PendingCN111592006AAvoid re-releaseImprove removal efficiencySilicon compoundsWater/sewage treatment by flocculation/precipitationEnvironmental engineeringClay soil

The invention discloses a preparation method of modified clay and an application method of the modified clay in directional recovery of microalgae, and relates to the field of biology. The method comprises the following steps: putting a modifier and clay into a reactor, adding a certain amount of deionized water, fully stirring, and uniformly mixing to prepare a modified clay turbid liquid; afteraging for a period of time at a certain temperature, centrifuging, drying and sieving to obtain the modified clay. The application method includes spraying the modified clay into a eutrophic water body to form floccules in the water body, and adsorbing algae cells; then scattering iron powder particles into the water body to form an iron-containing clay-algae cell floccule composite with the floccules already formed in the water body; and finally, putting an electromagnetic recovery device into the water body, electrifying to enable the device to have magnetism, attracting the iron-containingclay-algae cell floccule composite to the outer wall of the device, taking out the floccule composite from the water body, and collecting the floccule composite. Algae adsorbed by the clay is recycledashore, nutrient salt is prevented from being released again after algae cells settle, and meanwhile the removal efficiency is improved after clay modification.

Owner:SHANGHAI JIAO TONG UNIV

Oxidation modification system and method for desulfurization ash based on hot flue gas cyclic indirect heating

PendingCN110864555AImprove work efficiencyIncrease annual throughputFurnace typesPreheating chargesCold airHot air oven

The invention provides an oxidation modification system and method for desulfurization ash based on hot flue gas cyclic indirect heating, and belongs to the technical field of environmental engineering. The system comprises a rotary pre-heater, an oxidation kiln, an outer heating flue gas box, a rotary cooler, a heat exchanger jacket, a hot air furnace and a high temperature circulating fan. The oxidation kiln is arranged at the rear part of the rotary pre-heater; the outer heating flue gas box is arranged out of the oxidation kiln; heat is supplied to the oxidation kiln by means of hot flue gas; the rotary cooler is arranged at the rear part of the oxidation kiln; cold air is introduced into the rotary cooler for cooling a material; the heat exchange jacket is arranged out of the rotary cooler; the heat exchanger jacket is connected to the hot air furnace; and the hot air furnace is connected to the high temperature circulating fan. The system has the advantages of low energy consumption, high oxidation efficiency, high treatment capacity and the like, and is suitable for industrial production and application.

Owner:BEIJING BEIKE ENVIRONMENTAL ENG CO LTD

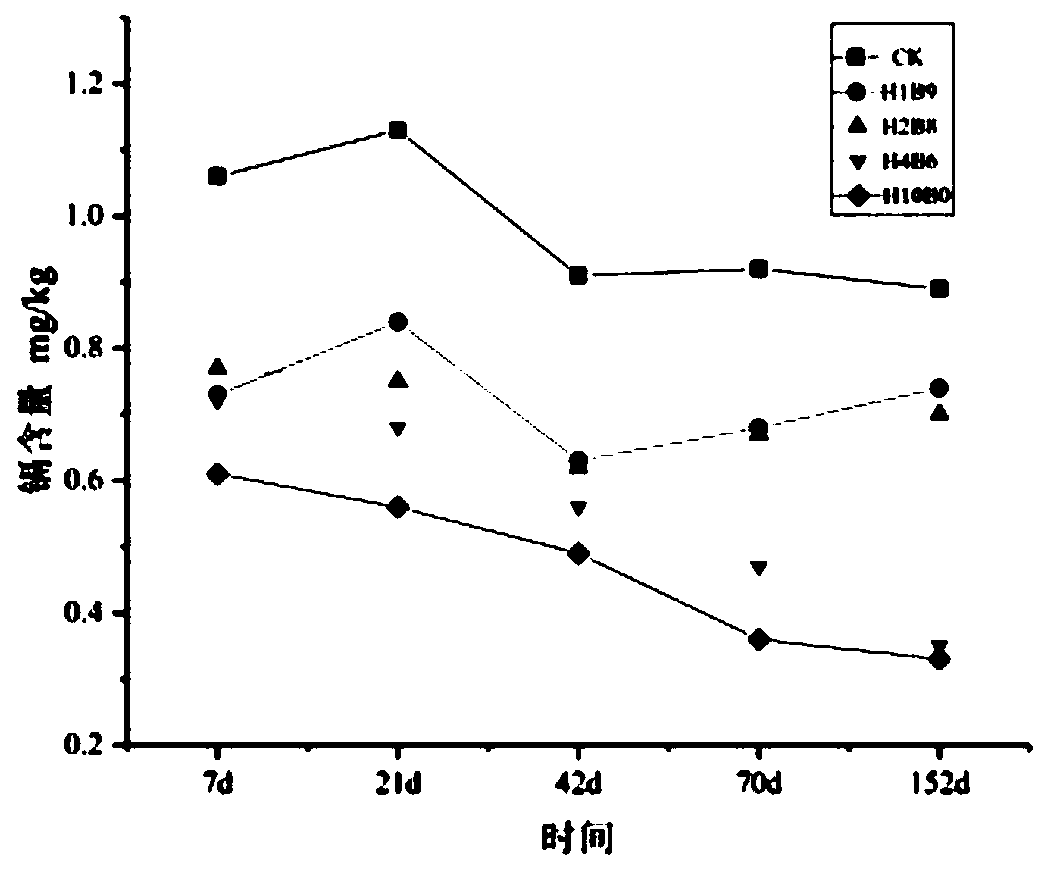

Method for repairing cadmium contaminated soil through compound soil repair agent

ActiveCN110420985AImprove pore structureImprove adsorption capacityContaminated soil reclamationOrganic fertilisersCalcium silicateHydroxylapatite

The invention provides a method for repairing cadmium contaminated soil through a compound soil repair agent. The method comprises the following steps that the compound soil repair agent is prepared firstly, then the compound soil repair agent and the cadmium contaminated soil are evenly mixed, finally, rice seedling is planted, the soil moisture content is maintained to be 50%-80%, the repairingtime is the overall growing period of rice, the compound soil repair agent is prepared from hydroxylapatite-calcium silicate composite and biochar with the mass ratio being (1:9) to (9:1), the addingamount accounts for 5wt% of the total soil mass of repaired soil, optimally, the mass ratio of the hydroxylapatite-calcium silicate composite to the biochar is (1:9) to (4:6), the more optimal ratio of the hydroxylapatite-calcium silicate composite to the biochar is 4:6, the hydroxylapatite-calcium silicate composite and the biochar act synergistically, in the short period-repairing for 7 days, the compound repair agent can effectively decrease the cadmium content in soil, meanwhile, the cadmium in the soil is converted from the active form to the stable form, bio-availability is effectively lowered, after the rice grows for 152 days, the cadmium metal content in the root and stem of the rice is significantly decreased, and absorbing of the rice to cadmium in the soil is effectively inhibited.

Owner:HUNAN UNIV

Preparation method and application of magnetic renewable mercury removal agent

ActiveCN113769701AImprove efficiencyLarge capacityGas treatmentOther chemical processesCopper chlorideFlue gas

The invention discloses a preparation method and application of a magnetic renewable mercury removal agent. According to the method, natural iron minerals are subjected to high-temperature roasting to remove part of sulfur and then are converted into magnetic iron minerals, copper chloride is added for modification treatment, and the magnetic renewable mercury removal agent with excellent mercury removal performance is obtained after mechanical grinding and activation. The magnetic mercury removal agent is placed in a fixed bed, a fluidized bed and a wet flue gas purification system or sprayed into flue gas to be in contact with mercury in the flue gas,converts gaseous mercury into a stable compound, and achieves curing removal of the gaseous mercury; the mercury-loaded mercury removal agent is separated out after magnetic separation, and the magnetic mercury removal agent can be recycled after being subjected to high-temperature mercury desorption. The raw materials of the magnetic renewable mercury removal agent are natural and easily available and have abundant reserves; the preparation method of the magnetic renewable mercury removal agent is simple; and the magnetic renewable mercury removal agent has large mercury adsorption capacity and fast adsorption rate, can be recycled, substantially reduces the mercury removal cost, and has good practical value.

Owner:CENT SOUTH UNIV

Water-based sepiolite organic-inorganic mineral coating material and preparation method thereof

InactiveCN111978795AImprove adsorption capacityWith decompositionCoatingsPhysical chemistryMineralogy

The invention provides a water-based sepiolite organic-inorganic mineral coating material and a preparation method thereof. The water-based sepiolite organic-inorganic mineral coating material comprises 20-30% of water, 15-20% of sepiolite powder, 5-10% of organic resin, 10-15% of inorganic cementing material, 3-5% of nano titanium dioxide, 25-45% of filler and 1.5-4.5% of additive. The preparation method of the water-based sepiolite organic-inorganic mineral coating material comprises the following steps: adding the components according to a specific sequence, and uniformly stirring. The water-based sepiolite organic-inorganic mineral coating material solves the technical problems that the organic paint influences the environment and influences the efficiency of the functional componentsand the inorganic paint is easy to crack in the prior art.

Owner:湖南蓝天豚住工科技有限公司

Preparation method of functional dry powder diatom wall material accessory

InactiveCN109679385AImprove adsorption capacityAvoid re-releaseCoatingsDefoaming AgentsWall material

The invention discloses a preparation method of a functional dry powder diatom wall material accessory, and relates to the field of diatom ooze. The functional dry powder diatom wall material accessory consists of the following raw materials: non-calcined high-quality diatomite, a nano TiO2 / diatomite photocatalytic composite material and an additive; and the additive comprises a dry powder wettingagent, a dry powder dispersing agent and a dry powder defoaming agent. The functional dry powder diatom wall material accessory has the beneficial effects that the adsorption performance is quite high; and the accessory has the ability to decompose harmful substances, the harmful substances are prevented from being released again, and the formaldehyde-purifying property of the accessory reaches 90% or more.

Owner:湖南蓝天豚住工科技有限公司

Purification treatment device for removing VOC

PendingCN110772976ACompact structureConvenient after-sales maintenanceGas treatmentDispersed particle separationPhysical chemistryPhoto catalysis

The invention relates to a purification treatment device for removing VOC. The purification treatment device comprises: an adsorption module comprising an adsorption unit and a heating member; a gas flow driving module arranged on the upstream or the downstream of the adsorption module in a gas flow direction and used for driving a gas flow to flow; a photocatalysis module arranged at the downstream of the adsorption module along the gas flow direction and used for adsorbing VOC in the gas flow flowing through the photocatalysis module and photocatalytically decomposing the VOC; and a controlmodule connected to the gas flow driving module and the heating member and used for controlling the gas flow speed and the heating temperature of the adsorption unit. According to the invention, the purification treatment device has an adsorption working mode, a decomposition working mode or a combination of the adsorption wording mode and the decomposition working mode, wherein the adsorption module and the gas flow driving module are operated in the adsorption working mode, and in the decomposition working mode, the photocatalysis module, the gas flow driving module and the control module are operated, and the gas flow speed and / or the heating temperature of the adsorption unit are / is controlled through the control module, so that the VOC released by the adsorption unit is completely orpartially adsorbed by the photocatalysis module.

Owner:HONEYWELL PERFORMANCE MATERIALS & TECH (CHINA) CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com