In-situ repairing material of bottom mud of black and odorous water body and preparation method of in-situ repairing material

A technology for in-situ restoration of black and odorous water bodies, applied in chemical instruments and methods, water/sludge/sewage treatment, sludge detoxification, etc. And growth pollution, sludge dehydration difficulties and other problems, to achieve good phosphorus and nitrogen removal effect, promote reduction, and less equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

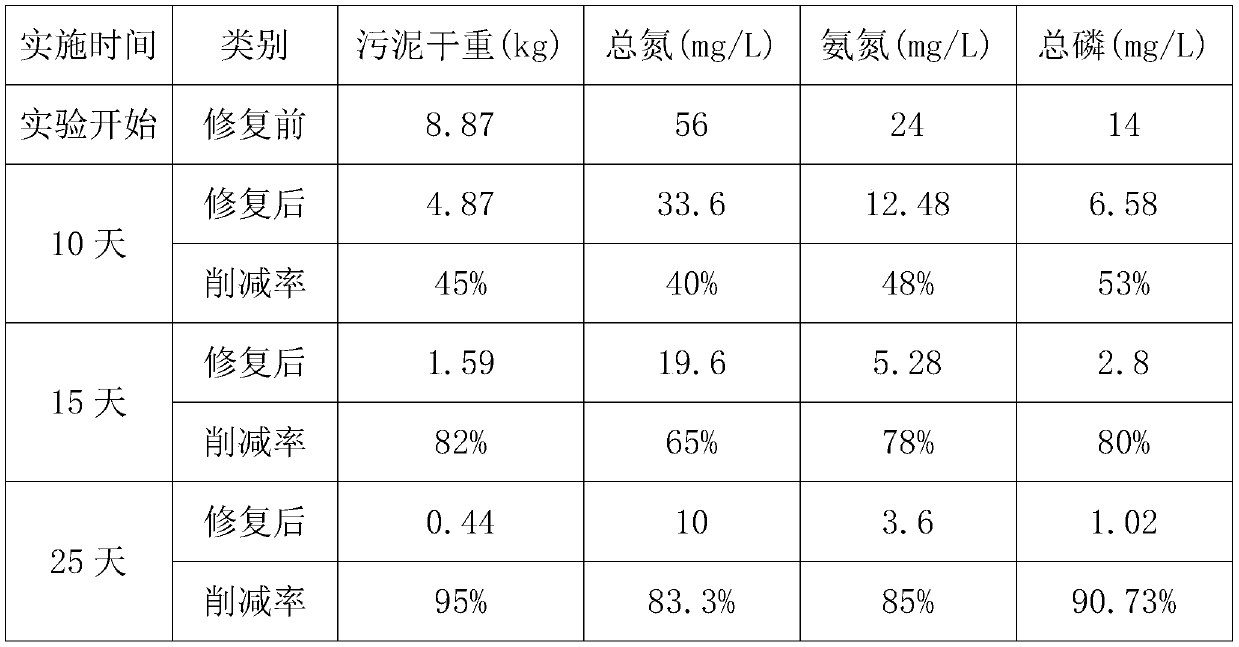

Examples

Embodiment 1

[0042] Select 200 grams of palygorskite according to the corresponding ratio and pass through a 300-mesh filter sieve after being pulverized to obtain powdery palygorskite. Pass through a 30-mesh sieve to obtain powdery iron scrap, and 120 grams of bentonite are pulverized and pass through an 80-mesh sieve to obtain filtered bentonite. Mix the obtained powdery palygorskite, powdery zeolite, powdery scrap iron scraps and filtered bentonite, stir evenly and add 10 grams of lanthanum chloride aqueous solution with a mass concentration of 0.2%, and put it into a granulator to obtain 0.8mm The particle size of the spherical material is dried at 80 degrees Celsius for 1 hour, then sintered at 280 degrees Celsius for 1 hour and then cooled to room temperature to obtain the finished product.

Embodiment 2

[0044]Select 200 grams of palygorskite according to the corresponding ratio and pass through a 1500 mesh filter sieve after crushing to obtain powdery palygorskite, and 180 grams of zeolite pass through a 700 mesh filter sieve after crushing to obtain powdery zeolite. Pass through a 100-mesh sieve to obtain powdery waste iron scraps, and 120 grams of bentonite are pulverized and pass through a 450-mesh sieve to obtain filtered bentonite. The obtained powdery palygorskite, powdery zeolite, powdery scrap iron scraps and filtered bentonite are mixed, after stirring evenly, add 60 grams of lanthanum chloride aqueous solution with a mass concentration of 0.5%, and put it into a granulator to obtain 5mm pellets. diameter pellet material, the pellet material was dried at 200 degrees Celsius for 5 hours, then sintered at 800 degrees Celsius for 5 hours and then cooled to room temperature to obtain the finished product.

Embodiment 3

[0046] Select palygorskite 800 grams according to corresponding ratio and cross 300 mesh sieves after pulverizing, obtain powdery palygorskite, zeolite 750 grams pass 100 mesh sieves after pulverizing, obtain powdery zeolite, scrap iron scrap 680 grams after pulverizing Pass through a 30-mesh sieve to obtain powdery iron scrap, and 500 grams of bentonite are pulverized and pass through an 80-mesh sieve to obtain filtered bentonite. Mix the obtained powdery palygorskite, powdery zeolite, powdery scrap iron scraps and filtered bentonite, stir evenly and add 10 grams of lanthanum chloride aqueous solution with a mass concentration of 0.2%, and put it into a granulator to obtain 0.8mm The particle size of the spherical material is dried at 80 degrees Celsius for 1 hour, then sintered at 280 degrees Celsius for 1 hour and then cooled to room temperature to obtain the finished product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com