Method and reagent for repairing mercury and chromium deep contaminated soil by cooperation of anaerobic sulfate reducing bacteria and iron-based material

A technology for iron-based materials and polluted soil, which is applied in the restoration of polluted soil, chemical instruments and methods, soil conditioning materials, etc., to achieve long-term stable performance, reduced bioavailability, and low cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

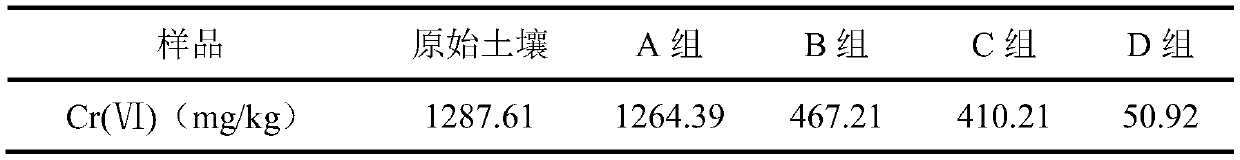

[0026] The Cr(Ⅵ)-contaminated soil samples with a depth of 20-80 cm were taken from Changsha Chromium Salt Factory. After air-drying and sieving (60 mesh), the Cr(Ⅵ) content in the soil was analyzed, as shown in Table 1.

[0027] Preparation of iron-based materials: Mix oxalic acid and phillips (100g) at a ratio of 2:1, add 600mL of deionized water, heat up to 80°C, and continue stirring for 36 hours. After the reaction is completed, filter, wash and dry to obtain Iron-based materials.

[0028] Cultivation of anaerobic sulfate-reducing bacteria: the bacteria were inoculated in the deoxygenated liquid medium (KH 2 PO 4 0.5g / L, NH 4 Cl 1g / L, CaCl 2 0.1g / L, MgSO 4 ·7H 2 O 2.5g / L, sodium lactate 3.5g / L, pH value is 6.5), growth temperature is 30 ℃, grow to the logarithmic phase and wait for use. Simulated remediation of deep Cr(Ⅵ) contaminated soil: the remediation experiment was divided into four groups A, B, C and D, group A did not add remediation agents (no bacteria or ...

Embodiment 2

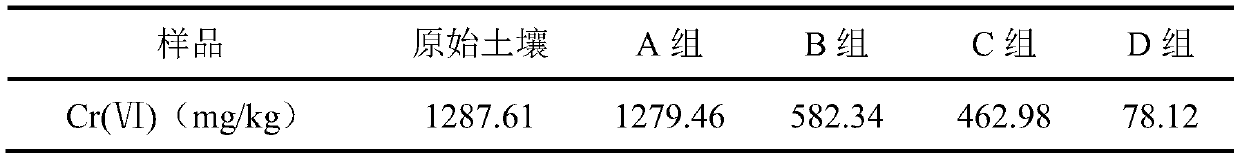

[0033] The Cr(Ⅵ) contaminated soil sample is consistent with the sample in Example 1.

[0034] Preparation of iron-based materials: Mix oxalic acid and biotite (50g) at a ratio of 3:2, add 200mL of deionized water, heat up to 90°C, and continue stirring for 6 hours. After the reaction is completed, filter, wash and dry to obtain Iron-based materials.

[0035] Cultivation of anaerobic sulfate-reducing bacteria: the bacteria were inoculated in the deoxygenated liquid medium (KH 2 PO 4 0.5g / L, NH 4 Cl 1g / L, CaCl 2 0.1g / L, MgSO 4 ·7H 2O 2.5g / L, sodium lactate 3.5g / L, pH value is 6.5), growth temperature is 30 ℃, grow to the logarithmic phase before use, the bacterial density in the bacterial liquid is 7*10 8 individual / mL. Simulated remediation of deep Cr(Ⅵ) contaminated soil: the remediation experiment was divided into four groups A, B, C and D, group A did not add remediation agents (no bacteria or iron-based materials), group B added remediation agents It is an iron-ba...

Embodiment 3

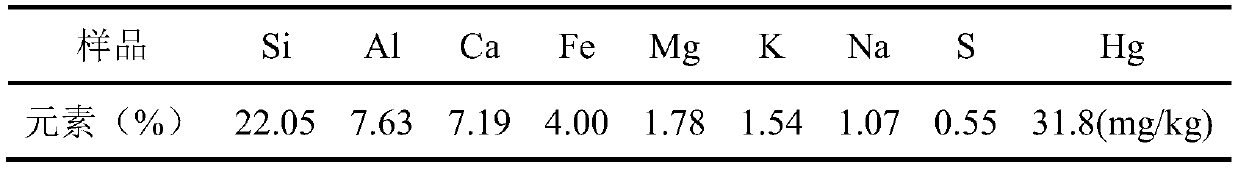

[0040] The Hg-contaminated soil samples with a depth of 20-100 cm were taken from Tongren, air-dried and sieved (40 mesh), and the content and form of Hg in the soil are shown in Table 3 and Table 4.

[0041] Preparation of iron-based materials: Mix oxalic acid and iron-aluminum garnet (100g) at a ratio of 2:1, add 600mL of deionized water, heat up to 80°C for 36 hours, and after the reaction is completed, filter, wash and dry to obtain iron base material.

[0042] Cultivation of anaerobic sulfate-reducing bacteria: the bacteria were inoculated in the deoxygenated liquid medium (KH 2 PO 4 0.5g / L, NH 4 Cl 1g / L, CaCl 2 0.1g / L, MgSO 4 ·7H 2 O 2.5g / L, sodium lactate 3.5g / L, pH value is 6.5) to cultivate, the growth temperature is 30 ℃, after growing to the logarithmic phase, it is used for the remediation of contaminated soil.

[0043] Simulated remediation of deep Hg-contaminated soil: the remediation experiments were divided into four groups: A, B, C and D. Group A had no...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com