Enhanced system and method for adsorption removal of mercury in coal-fired flue gas

A coal-fired flue gas removal technology, applied in lighting and heating equipment, etc., can solve the problems of increasing the amount of adsorbents and the cost of mercury removal, limiting the efficacy of active agents and adsorbents, and avoiding re-release and secondary pollution. , Stabilize mercury removal effect and reduce mercury content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

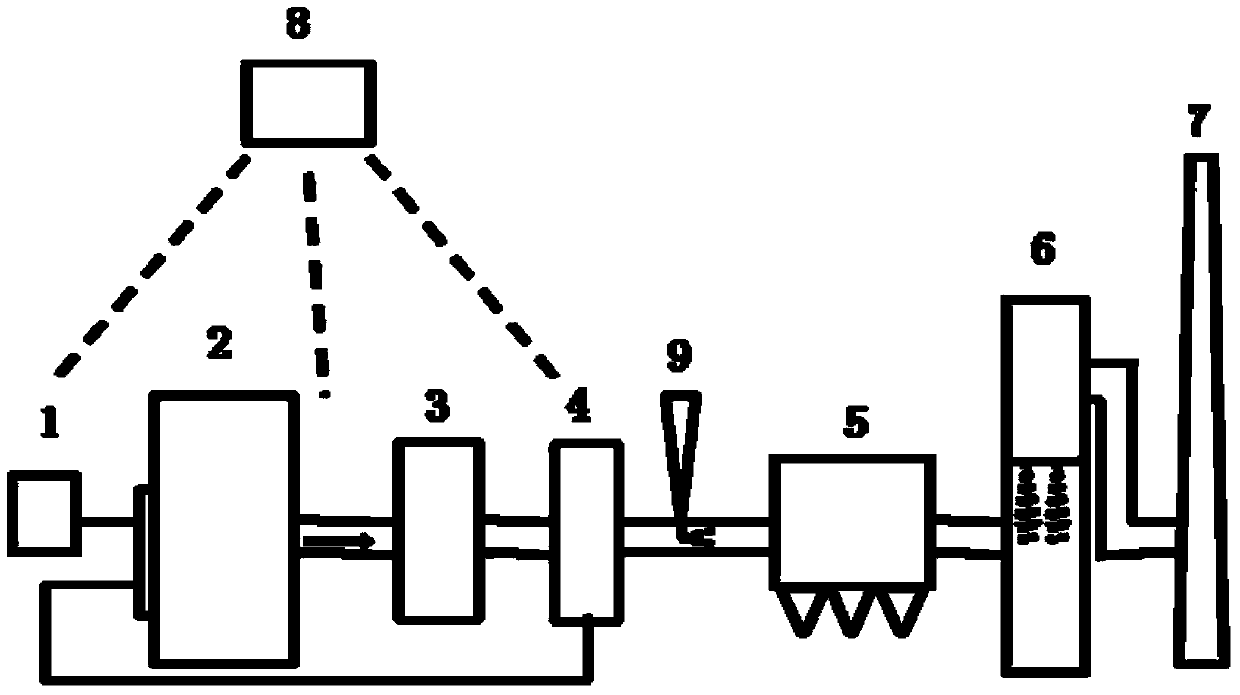

[0022] As shown in the drawings, the present invention is a system for enhanced adsorption and removal of mercury in coal-fired flue gas, which includes a coal feeding system 1, a boiler body 2, a denitrification device 3, an air preheater 4, a dust removal device 5, Desulfurization device 6 and chimney 7, additive addition system 8 installed on coal feeding system 1, boiler body 2, denitrification device 3 or air preheater 4, and adsorbent installed between air preheater 4 and dust removal device 5 Injection system9.

[0023] The above-mentioned system strengthens the method of adsorption and removal of mercury in coal-fired flue gas. First, combined with the actual situation of the power plant, it includes the coal type, the coal feeding system 1, the boiler body 2, the denitrification device 3, the air preheater 4, and the structur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com