Stabilizing method of arsenic-containing waste residues

A technology of waste residue and aluminum salt, applied in chemical instruments and methods, solid waste removal, transportation and packaging, etc., can solve the problems of unsatisfactory stabilization effect of arsenic-containing waste residue, avoid secondary pollution, avoid re-release, The effect of improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

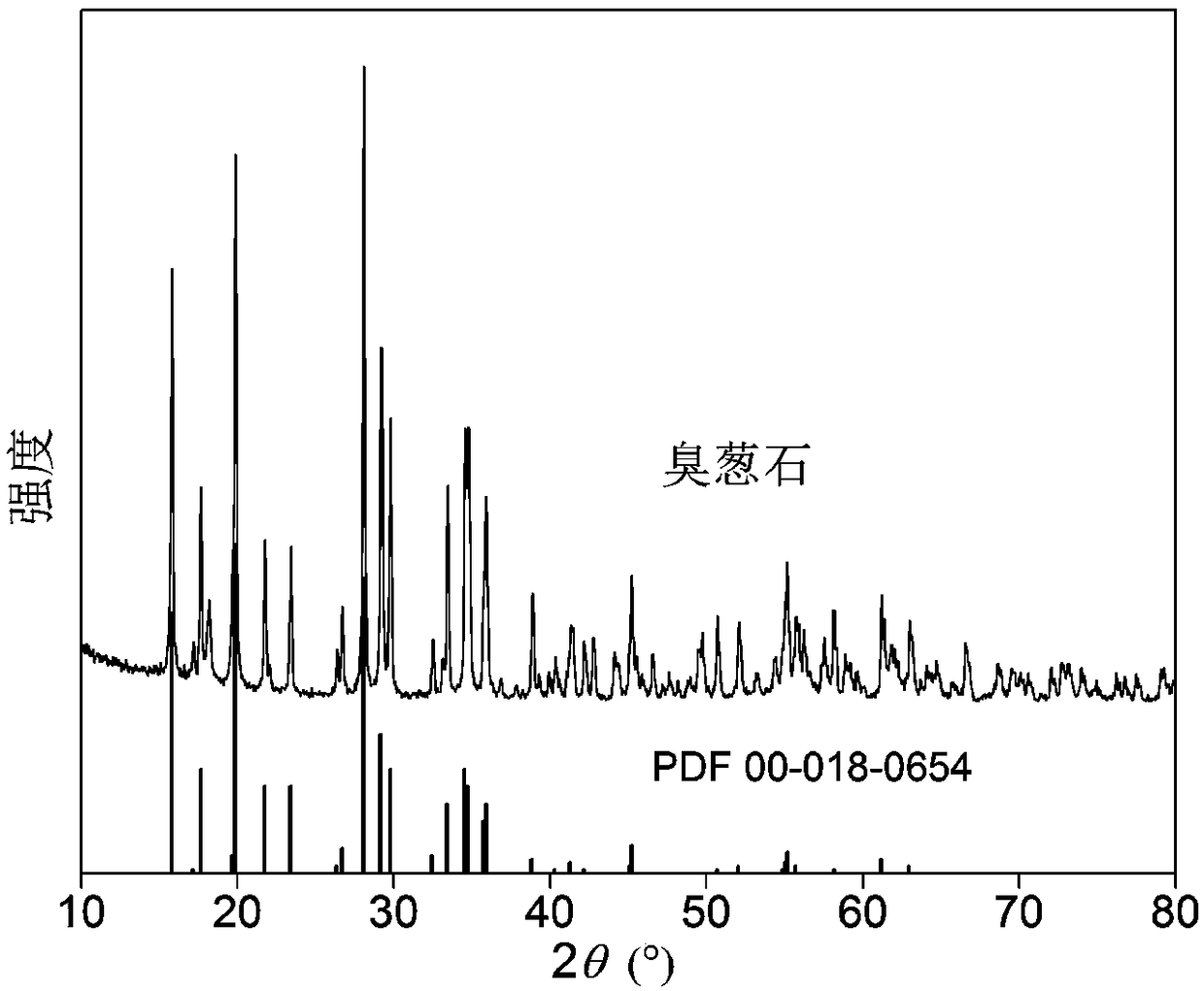

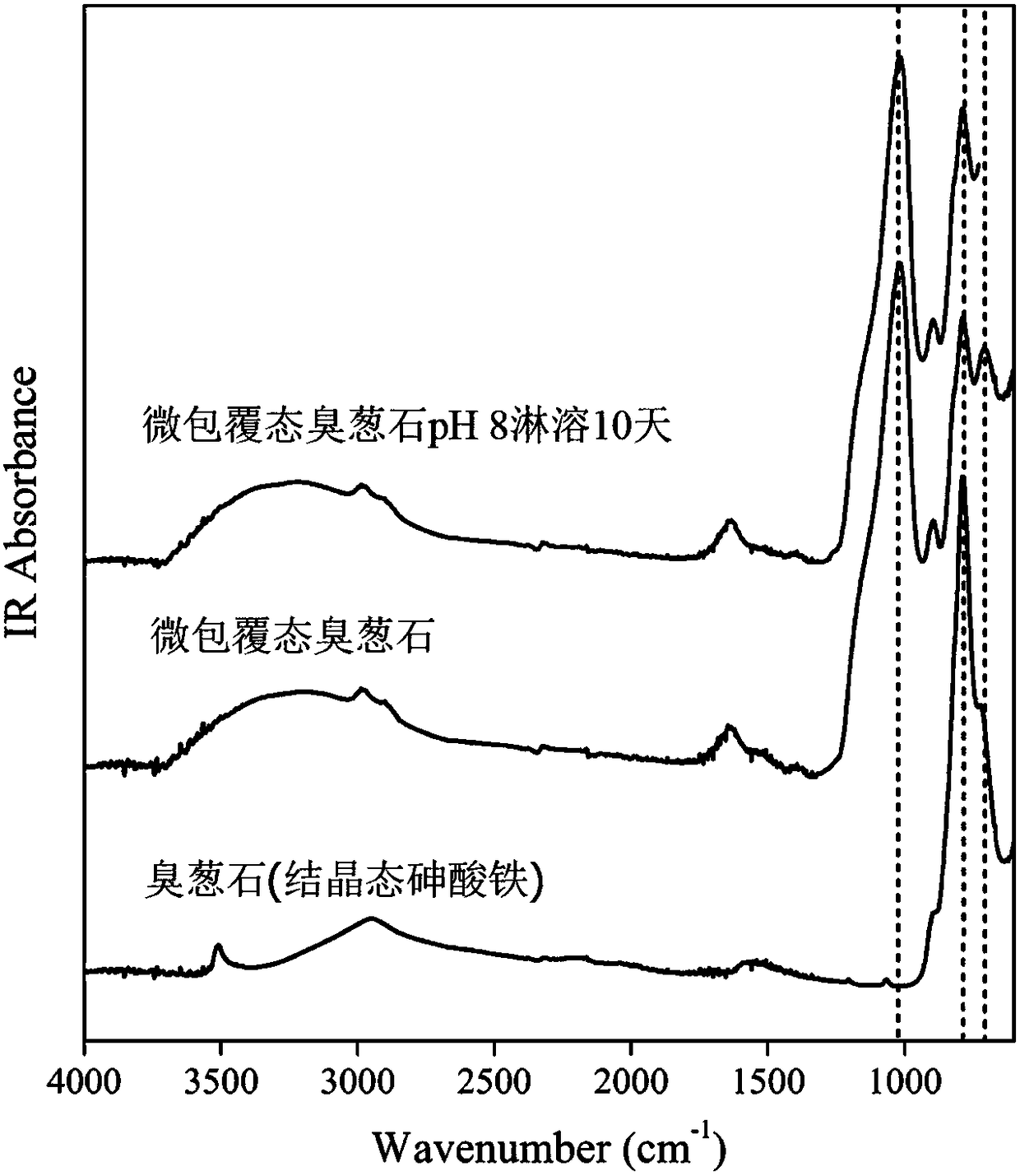

[0058] Scorod slag (crystalline ferric arsenate): containing 33wt.% of As, 23wt.% of iron and the rest of hydrogen and oxygen. Mix 20g of sororid slag with 100ml of water to obtain a mixed slurry of scorodil slag , Add 20mL of aluminum sulfate solution and 20mL of sodium silicate solution dropwise into scorodite slag mixed slurry under mechanical stirring, wherein the molar ratio of aluminum in aluminum sulfate solution to silicon in sodium silicate is 0.6:1, and silicic acid The molar ratio of silicon in sodium solution to arsenic in scorodite slag is 1:1. After the dropwise addition, the metathesis reaction was continued for 3 hours, and the pH value of the micro-coating process was always controlled within the range of 2-5 by acid or alkali.

[0059] Detect the arsenic content in the slurry in the micro-coating process (As content detection method is: use potassium borohydride test reagent to measure by atomic fluorescence spectrometer, and perform single-point calibration ...

Embodiment 2

[0065] Scoord slag (crystalline ferric arsenate): content of As: 33wt.%, scorodid slag 20g and 100ml water are mixed to obtain scorodil slag mixed slurry, aluminum sulfate solution and silicic acid are mixed under mechanical stirring The sodium solution is added dropwise to the mixed slurry of scorodonite slag at the same time, wherein the molar ratio of aluminum in the aluminum sulfate solution to silicon in the sodium silicate is 0.5:1, and the molar ratio of silicon in the sodium silicate solution to arsenic in the scorodonite slag is It is 2:1. The pH value of the micro-coating process is always controlled within the range of 2-5 by using acid or alkali. After the dropwise addition, the metathesis reaction was continued for 3 hours, and solid-liquid separation was carried out to obtain the filtrate and scorodite waste residue treated with micro-coating stabilization.

[0066] According to the method in Example 1, the arsenic concentration of the slurry in the micro-coatin...

Embodiment 3

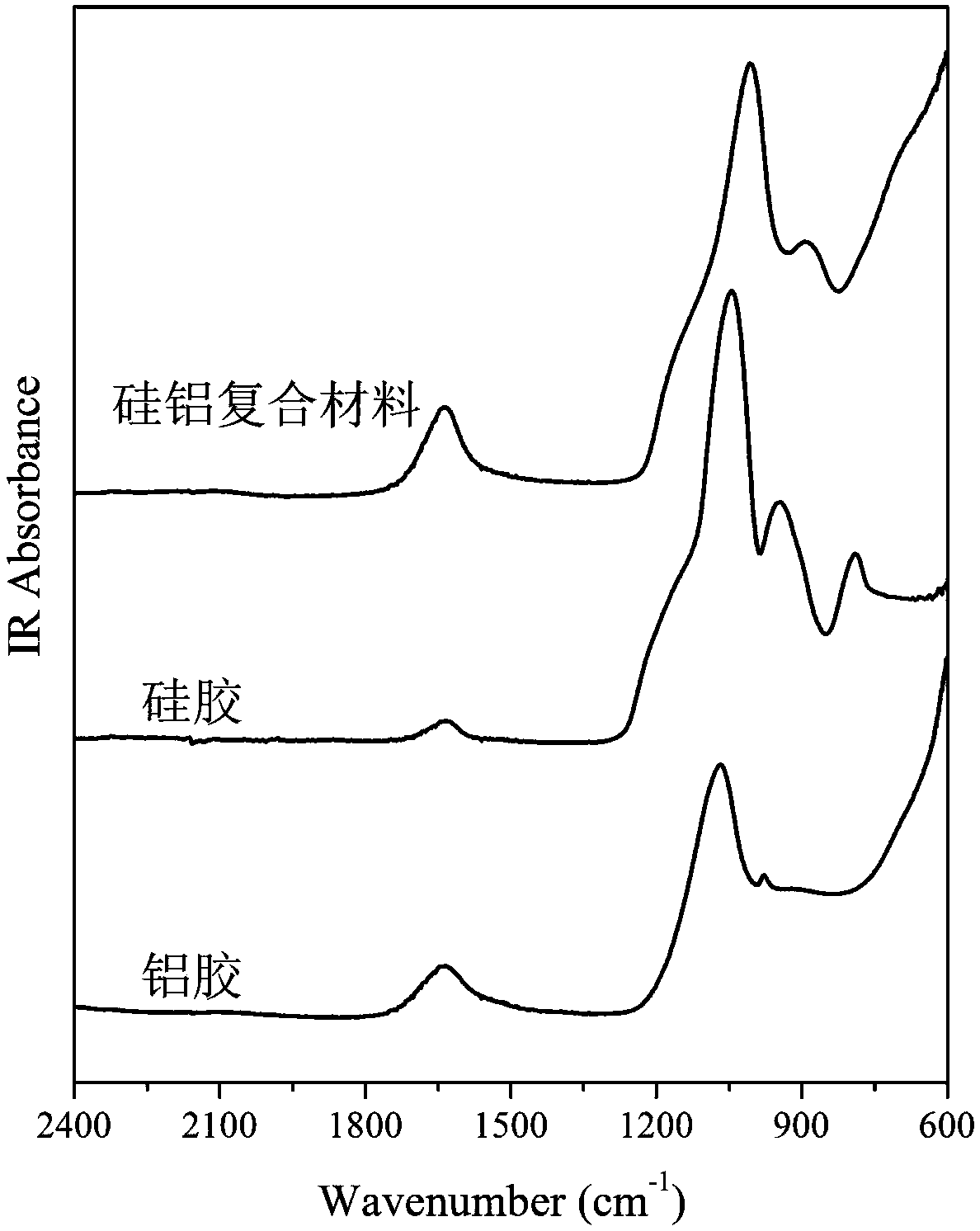

[0073] Scorodor slag (crystalline ferric arsenate): content of As: 33wt.%. Under mechanical stirring, adjust the mixed solution of aluminum sulfate solution and sodium silicate solution to a pH of 3 to 5 to form a mixed slurry of aluminum silicate composite material, and add scorodite slag to the mixed slurry, and the aluminum sulfate solution The molar ratio of silicon in aluminum and sodium silicate is 0.6:1, and the molar ratio of silicon in sodium silicate solution and arsenic in scorodite slag is 1.5:1. The pH value of the micro-coating process is always controlled within the range of 3-5 by using acid or alkali. After the dropwise addition, the metathesis reaction was continued for 3 hours, and solid-liquid separation was carried out to obtain the filtrate and scorodite waste residue treated with micro-coating stabilization.

[0074] According to the method in Example 1, the arsenic concentration of the micro-coating process liquid was detected, and the arsenic concentr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com