Industrial wastewater remediation material and application thereof, and treatment method of industrial wastewater containing cobalt-nickel divalent metal cations

A technology for industrial wastewater and restoration materials, which is applied in water/sewage treatment, adsorption water/sewage treatment, water/sludge/sewage treatment, etc. It can solve problems such as easy analysis of heavy metals, secondary pollution, and long-term restoration effects. Achieve the effect of reducing repair cost, reducing raw material dosage, and fast and efficient repair effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0034] In terms of parts by mass, the industrial wastewater restoration material provided by the present invention includes independently packaged component A, and the component A is rice straw biochar. In the present invention, the method for preparing rice straw biochar preferably includes: successively pulverizing and pyrolyzing rice straw to obtain rice straw biochar.

[0035] The present invention has no special limitation on the source of the rice straw, which can be obtained according to methods well known in the art. The present invention has no special limitation on the crushing process, as long as the rice straw can be crushed. In the present invention, the particle size of the pulverized material is preferably 20-200 mesh, more preferably 50-100 mesh. In the present invention, the pyrolysis temperature is preferably 700-900° C., more preferably 750-850° C., and the time is preferably 2-16 hours, more preferably 4-10 hours. In the present invention, the pyrolysis i...

Embodiment 1

[0056] The industrial wastewater used in this example comes from a non-ferrous metal smelting enterprise in Jiaxing City, Zhejiang Province, and is the untreated smelting wastewater of the enterprise. According to "Determination of Nickel in Water Quality by Flame Atomic Absorption Spectrophotometry (GB / T 11912-1989)" and "Determination of Total Cobalt in Water Quality 5-Chloro-2-(Pyridylazo)-1,3-Diaminobenzene Spectrophotometry (HJ 550-2009) "determination of nickel and cobalt content in the waste water, its nickel and cobalt content reached 242mg / L and 329mg / L respectively, and "copper, nickel, cobalt industrial pollutant discharge standard (GB 25467- 2010)" compared with the discharge standards of nickel and cobalt (both 1.0mg / L), exceeding the standard by 242 and 329 times respectively;

[0057] Restoration material ratio: component A rice straw biochar 57.1g, component B (aluminum chloride) 1g, component C (quicklime);

[0058] Among them, the preparation process of comp...

Embodiment 2

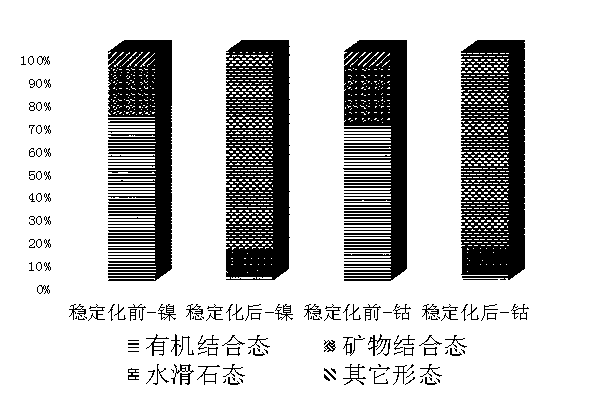

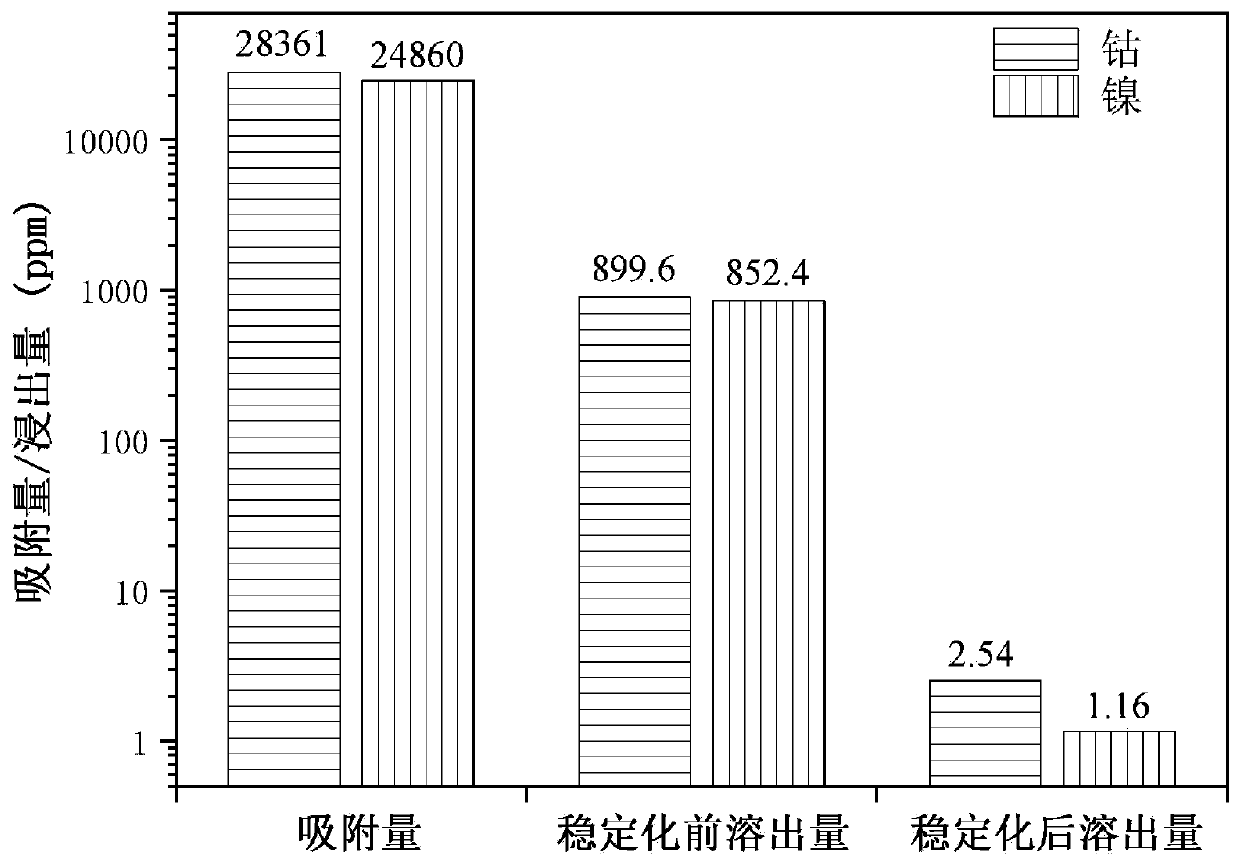

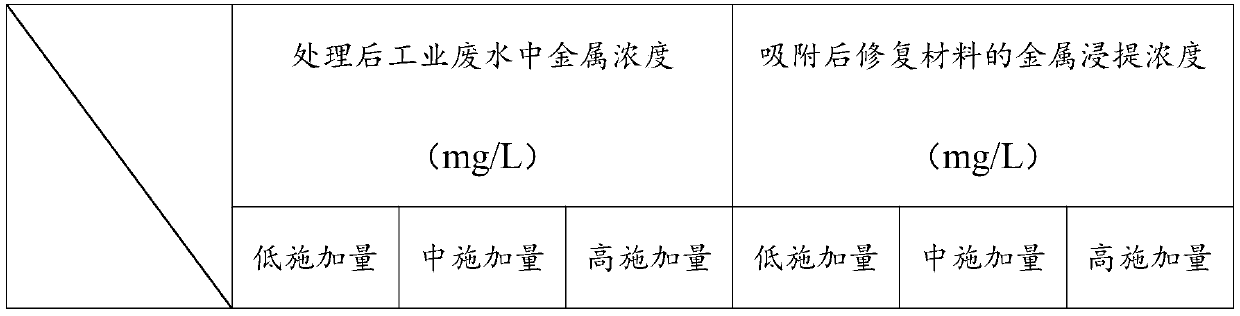

[0069] Study the pyrolysis temperature of rice straw and the application amount of component A on the adsorption and stabilization effect of industrial wastewater. In this example, the application amount of component A is 0.5 and 1% of the application amount of component A in Example 1, respectively. times and 5 times, respectively as low application amount group, middle application amount group and high application amount group, other conditions are the same as in Example 1, compare the contents of cobalt and nickel in industrial wastewater after treatment and cobalt and nickel in repair materials after adsorption The dissolution, as shown in Table 1.

[0070] Table 1 The adsorption and stabilization effects of component A with different pyrolysis temperatures and different application amounts on industrial wastewater (unit: mg / L)

[0071]

[0072]

[0073] According to Table 1, it can be seen that Component A obtained by pyrolysis at 700°C has the highest adsorption ca...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com